Ga-ZSM-5 catalyst as well as preparation method and application thereof

A technology of ga-zsm-5 and catalyst, which is applied in the field of catalysis, can solve the problems of complex preparation process and poor catalyst stability, and achieve the effects of simple process flow, reduced acid strength and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

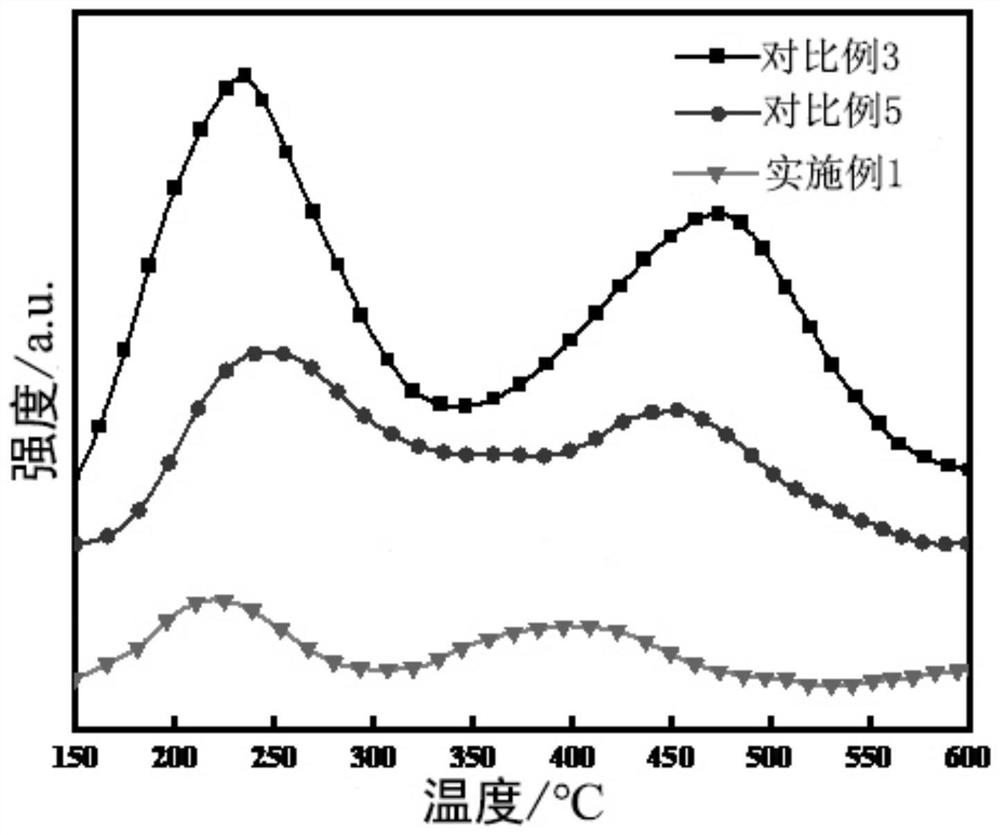

Embodiment 1

[0077] This embodiment provides a method for preparing a Ga-ZSM-5 catalyst. In parts by weight, the raw materials for preparing the Ga-ZSM-5 catalyst include: 75 parts of hydrogen-type Ga-ZSM-5 molecular sieves, binder 25 parts and 1 part of extrusion aid; the binding agent is pseudo-boehmite; the extrusion aid is squash powder;

[0078] Described preparation method comprises the steps:

[0079] (1) mixing hydrogen-type Ga-ZSM-5 molecular sieve, binder and extrusion aid according to the formula to obtain the compound;

[0080] (2) mixing nitric acid with a concentration of 10wt% and the compound obtained in step (1), extrusion molding, the addition of nitric acid is 50% of the mass of the compound; then drying and roasting are carried out successively, and cooled to room temperature to obtain Ga-ZSM -5 catalyst; the drying method includes drying at 100°C for 12 hours; the roasting is at 500°C for 6 hours;

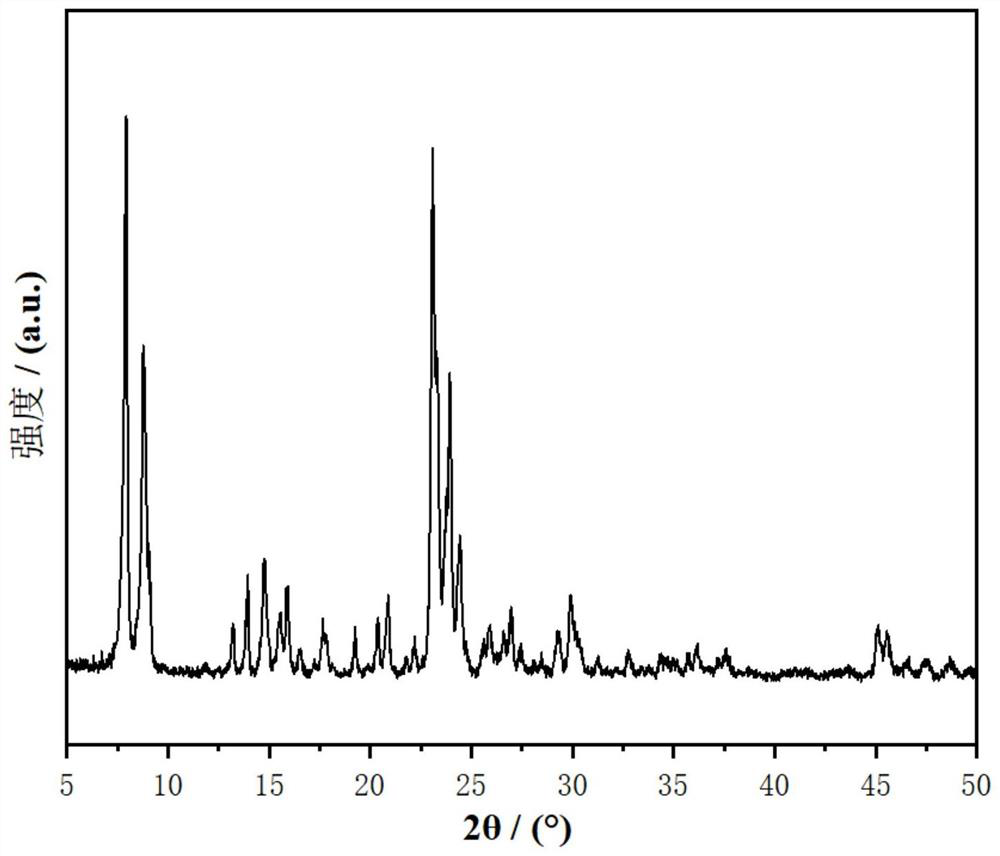

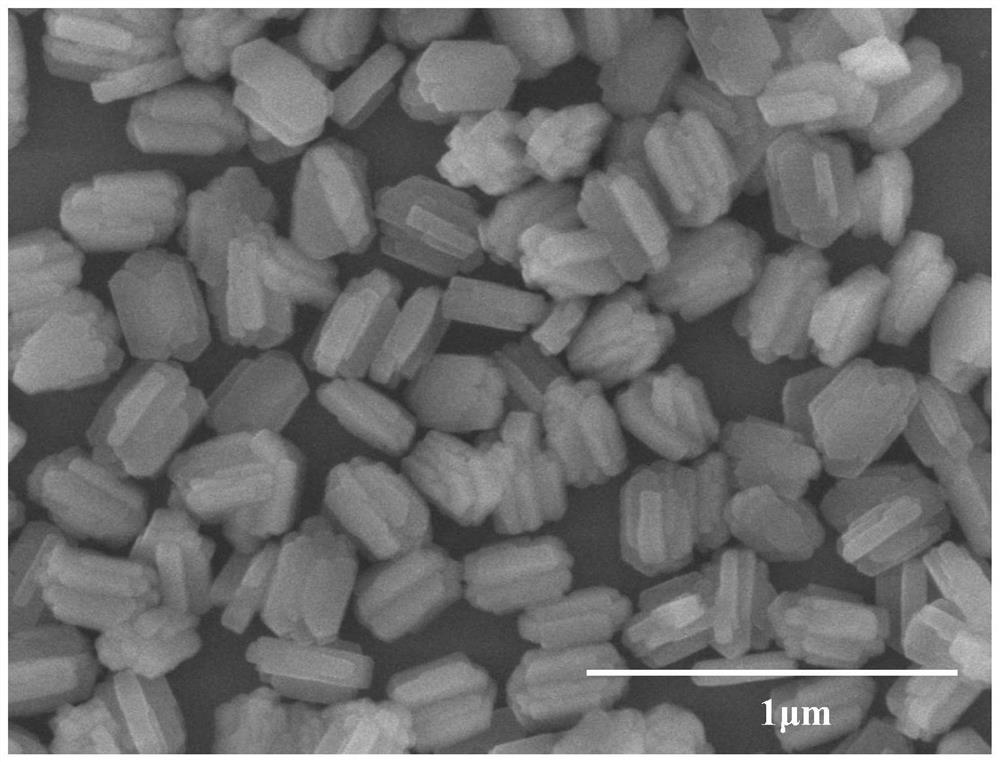

[0081] The preparation method of hydrogen type Ga-ZSM-5 molecular si...

Embodiment 2

[0088] This embodiment provides a method for preparing a Ga-ZSM-5 catalyst. In parts by weight, the raw materials for preparing the Ga-ZSM-5 catalyst include: 70 parts of hydrogen-type Ga-ZSM-5 molecular sieves, binder 30 parts and 0.5 parts of extrusion aid; the binder is γ-Al 2 o 3 ; The extrusion aid is lanthanum nitrate;

[0089] Described preparation method comprises the steps:

[0090] (1) mixing hydrogen-type Ga-ZSM-5 molecular sieve, binder and extrusion aid according to the formula to obtain the compound;

[0091] (2) mixing sulfuric acid with a concentration of 8wt% and the compound obtained in step (1), extrusion molding, the addition of sulfuric acid is 30% of the mass of the compound; then drying and roasting are carried out successively, and cooled to room temperature to obtain Ga-ZSM -5 catalyst; the drying method includes drying at 90°C for 18 hours; the roasting is at 450°C for 8 hours;

[0092] The preparation method of the hydrogen-type Ga-ZSM-5 molecula...

Embodiment 3

[0094] This embodiment provides a method for preparing a Ga-ZSM-5 catalyst. In parts by weight, the raw materials for preparing the Ga-ZSM-5 catalyst include: 80 parts of hydrogen-type Ga-ZSM-5 molecular sieves, a binder 20 parts and 2 parts of extrusion aid; the binder is γ-Al 2 o 3 ; The extrusion aid is cerium nitrate;

[0095] Described preparation method comprises the steps:

[0096] (1) mixing hydrogen-type Ga-ZSM-5 molecular sieve, binder and extrusion aid according to the formula to obtain the compound;

[0097] (2) mixing phosphoric acid with a concentration of 15wt% and the compound obtained in step (1), extrusion molding, the addition of phosphoric acid is 60% of the mass of the compound; then drying and roasting are carried out successively, and cooled to room temperature to obtain Ga-ZSM -5 catalyst; the drying method includes drying at 120°C for 6 hours; the roasting is at 550°C for 4 hours;

[0098] The preparation method of the hydrogen-type Ga-ZSM-5 molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com