A method for synergistically fermenting wheat straw to prepare high-quality biological feed

A technology for wheat straw and biological feed is applied in the field of synergistic degradation and fermentation of wheat straw into high-quality biological feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The amino acid sequence of LiP (Protein ID: 1589173) in JGI database (https: / / jgi.doe.gov) Irpex lacteus CCBAS Fr.238 617 / 93v1.0 is shown as SEQ ID NO.3. Its coding sequence is codon optimized according to the codon preference of Schizosaccharomyces pombe, and the nucleotide sequence of the LiP gene after codon optimization is shown in SEQ NO.1.

[0037] Design primers to amplify the target gene sequence. The forward primer sequence is shown in SEQ ID NO.4, and the reverse primer sequence is shown in SEQ ID NO.5. 60°C for 30s, 72°C for 60s, 30 cycles). The primers were designed using the shuttle plasmid pREP as the template. The sequence of the forward primer is shown in SEQ ID NO.6, and the sequence of the reverse primer is shown in SEQ ID NO.7. , 72 ℃ 50s, 30 cycles). The target fragment was recovered and the product concentration was determined. figure 1 For the fragment map of the PCR product of the vector and the target gene, the above PCR product fragments were...

Embodiment 2

[0040] In this example, the enzymatic properties of recombinant LiP were determined.

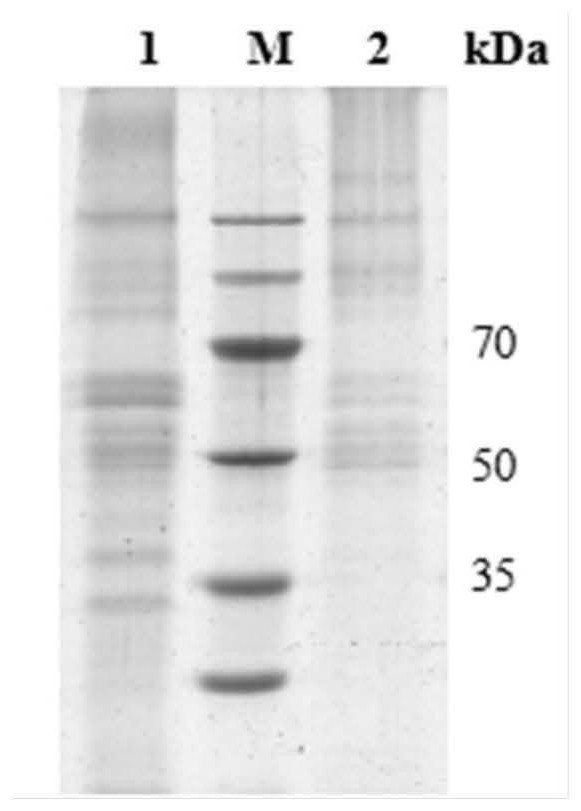

[0041] The S. pombe-pREP-lip obtained in Example 1 was expanded and cultured in YES liquid medium, and the culture medium was collected. After the culture medium was concentrated by ultrafiltration tube, SDS-PAGE and Western Blot verified the extracellular secretion of target protein by Schizosaccharomyces pombe. figure 2 is the SDS-PAGE electropherogram of Schizosaccharomyces pombe exocrine protein, image 3 Western Blot of S. pombe exocrine protein; combined with figure 2 and image 3 It can be seen that the recombinant LiP is expressed extracellularly in Schizosaccharomyces pombe, and the apparent molecular weight is about 37kDa. The change of the amount of extracellular secreted protein with the culture time is as follows: Figure 4 As shown in the figure, it can be seen from the figure that the amount of extracellular secreted protein of S.pombe-pREP-lip reached the peak on the 6t...

Embodiment 3

[0046] In this example, the inoculation amount of S.pombe-pREP-lip and S.pombe-pREP-mnp is 2%, the inoculation amount of N.crassa is 2%, the inoculation amount of L.fermentium is 1%, and the inoculation amount of C.utilis is 1% %; the inoculation of the bacterial classification is all fermented seed liquid; the preparation method of the fermented seed liquid of the bacterial classification is as follows:

[0047] N.crassa: Take the frozen N.crassa, inoculate it on the slant of PDA solid medium, incubate at 30 °C for 3 days until the spores are abundant, filter with 8 layers of gauze in the ultra-clean workbench, and repeat with sterilized water. Rinse the mature spores of N. crassa on the slant of the PDA, and the eluate is the spore suspension, which is counted with a hemocytometer, and adjusted to the number of 1 × 10 spores. 9 N.crassa spore suspension was then added to the PDA culture medium at 1% inoculum, and cultivated at 120 rpm, 30° C., in a constant temperature shake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com