A kind of high-strength and tough medium-entropy Crconi particle reinforced Cu-based composite material and preparation method thereof

A composite material and particle-reinforced technology, which is applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of increased strength, low equipment requirements, and excellent strong-plastic matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

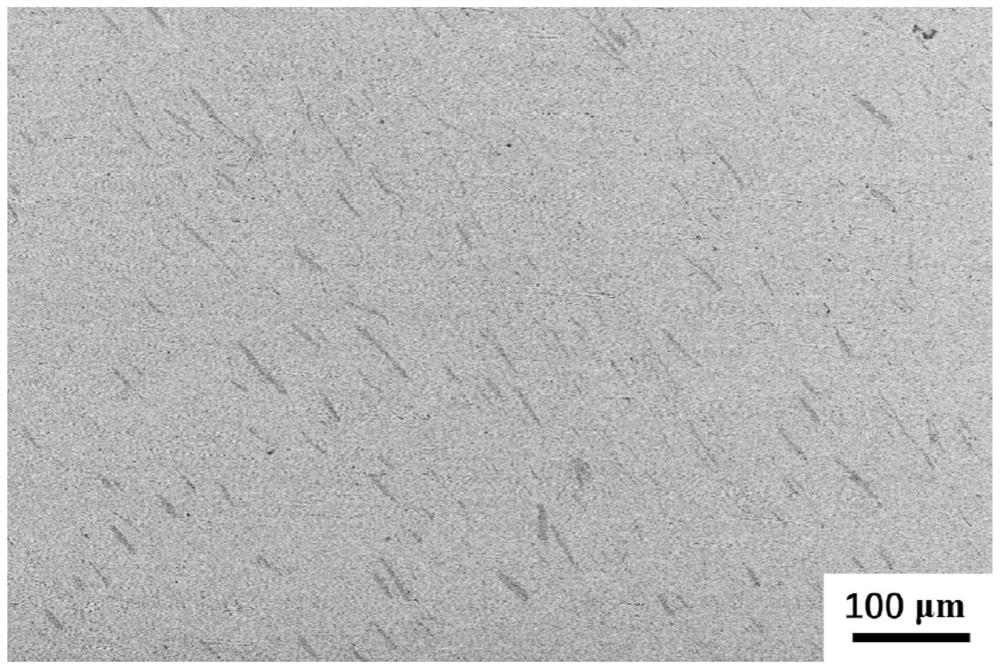

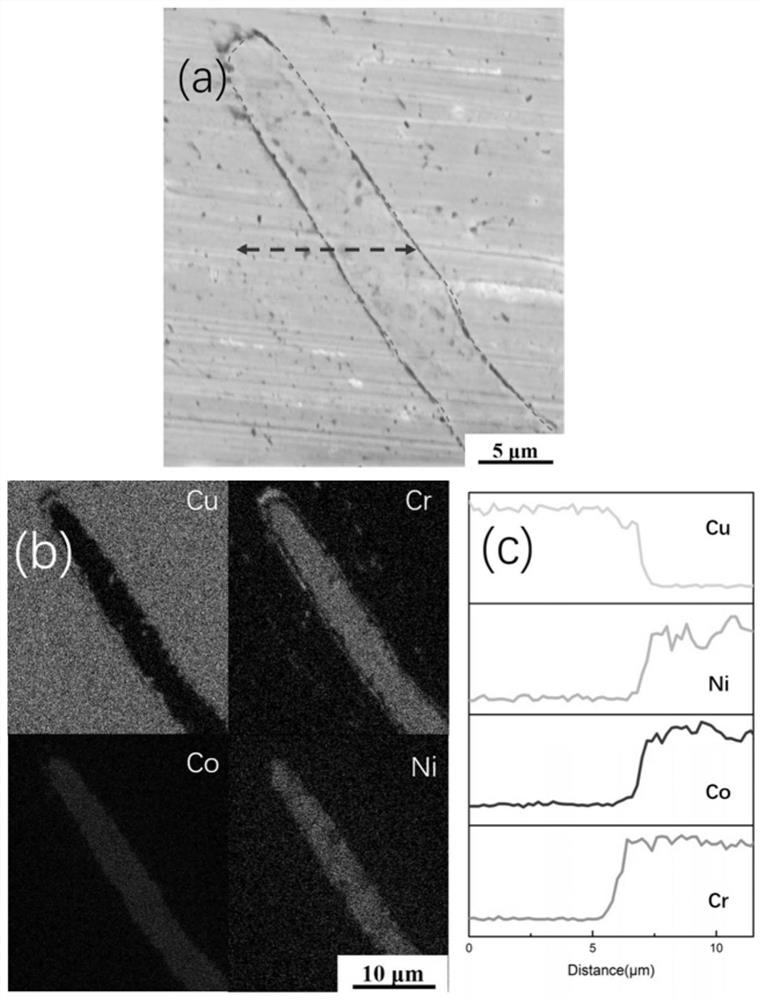

Embodiment 1

[0031] The CrCoNi medium-entropy alloy reinforced Cu-based matrix composite material is prepared, and the raw materials used are 95vol.% spherical pure Cu powder and 5vol.% spherical pure CrCoNi powder. Weigh the raw material powder according to the powder raw material ratio, and through the protection of argon, the pure Cu powder is pre-ground into flake Cu powder with the ball milling parameters of 350 rpm, ball milling time 5h, and ball-to-material ratio of 15:1. The rotation speed per minute, the ball milling time of 4 hours, and the ball milling parameters of the ball-to-material ratio of 20:1 pre-grind the CrCoNi powder into flaky CrCoNi powder. On this basis, the flaky Cu powder and the flaky CrCoNi powder were ball milled and mixed in an alcohol medium. The mixing parameters were ball mill speed 300 rpm, ball to material ratio 5:1, ball milling time 5h, and then vacuum filtration at room temperature into a green body. Then the green body was sintered in a spark plasma...

Embodiment 2

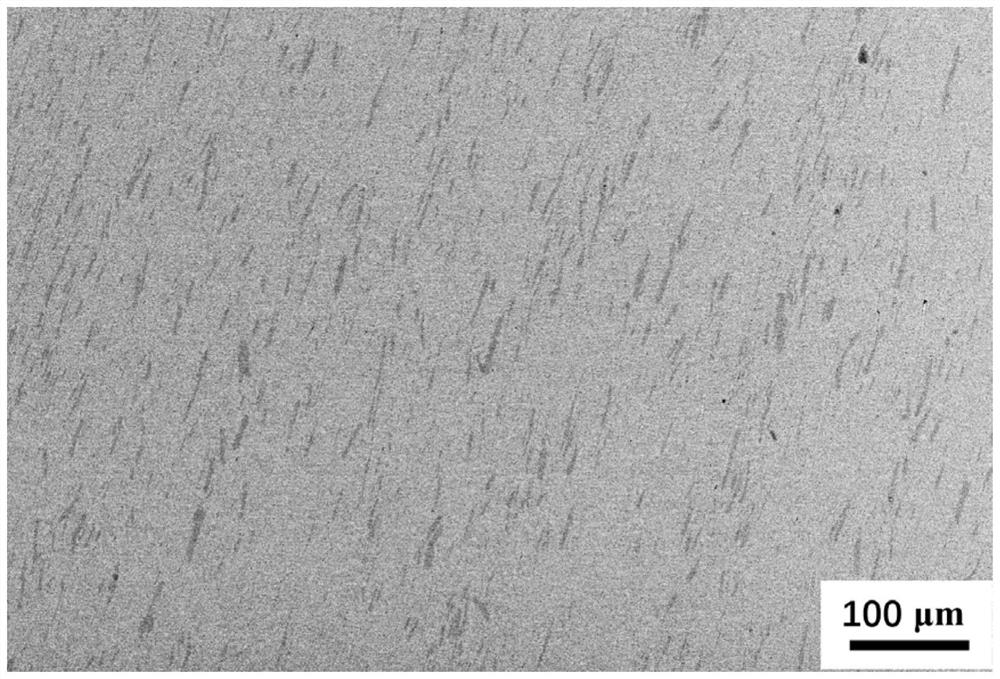

[0034] The CrCoNi medium entropy alloy reinforced Cu-based composite material is prepared, and the raw materials used are 90vol.% spherical pure Cu powder and 10vol.% spherical pure CrCoNi powder. Weigh the raw material powder according to the powder raw material ratio, and through the protection of argon, the pure Cu powder is pre-ground into flake Cu powder with the ball milling parameters of 350 rpm, ball milling time 5h, and ball-to-material ratio of 15:1. Pre-grind CrCoNi powder balls into flaky CrCoNi powder at a speed of revolution per minute, ball milling time of 4 hours, and ball-to-material ratio of 20:1. On this basis, the flaky Cu powder and the flaky CrCoNi powder were ball milled and mixed in an alcohol medium. The mixing parameters were ball mill speed 300 rpm, ball-to-material ratio 3:1, ball milling time 5h, and then vacuum filtration at room temperature into a green body. The green body was then sintered in a spark plasma sintering furnace at 950° C. for 20 ...

Embodiment 3

[0036] The CrCoNi medium entropy alloy reinforced Cu-based matrix composite material is prepared, and the raw materials used are 90vol.% spherical pure Cu powder and 10vol.% spherical pure CrCoNi powder. Weigh the raw material powder according to the powder raw material ratio, and through the protection of argon, use the ball milling parameters of 350 rpm, ball milling time 8h, and ball-to-material ratio 10:1 to ball mill pure Cu powder into flake Cu powder, and use 500 rpm CrCoNi powder is ball-milled into flaky CrCoNi powder at the speed of rotation per minute, ball milling time of 4 hours, and ball-to-material ratio of 10:1. On this basis, the flaky Cu powder and the flaky CrCoNi powder were ball milled and mixed in an alcohol medium. The mixing parameters were ball mill speed 350 rpm, ball to material ratio 4:1, ball milling time 4h, and then vacuum filtration at room temperature into a green body. The green body was then sintered in a spark plasma sintering furnace at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com