Wear-resistant, anti-oxidation and anti-seepage photoelectric hybrid cable

An optoelectronic hybrid cable, anti-seepage technology, applied in insulated cables, antifouling/underwater coatings, cables, etc., can solve problems such as the decline of mechanical properties of materials, and achieve the effects of long service life, not easy to age, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

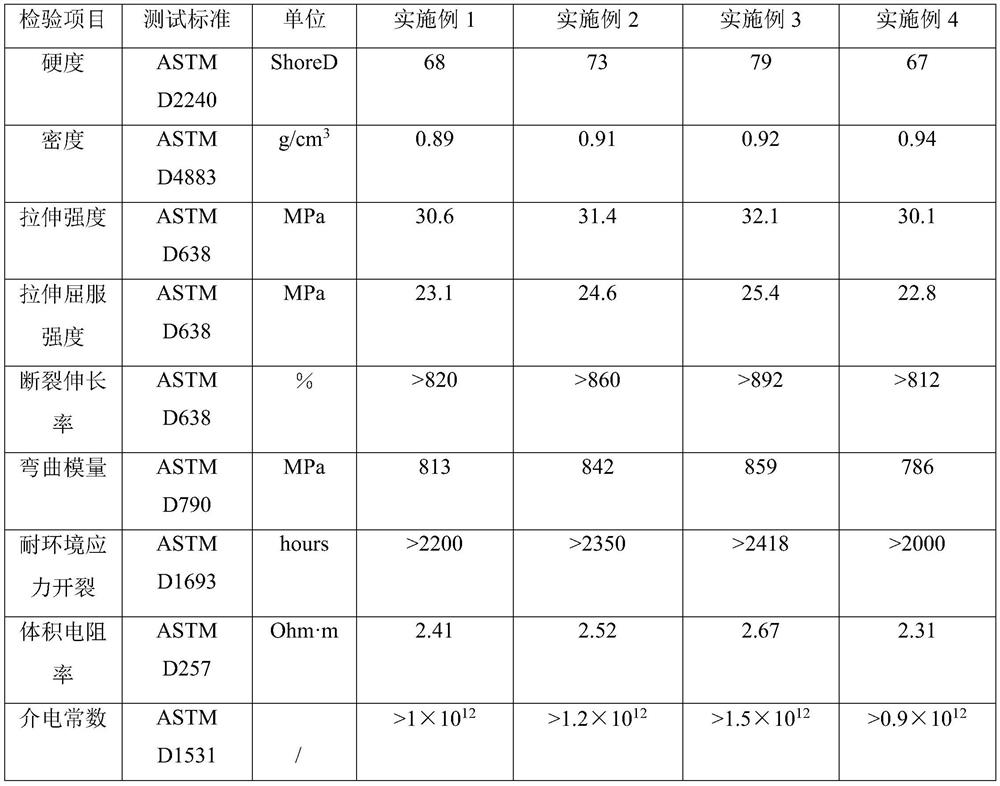

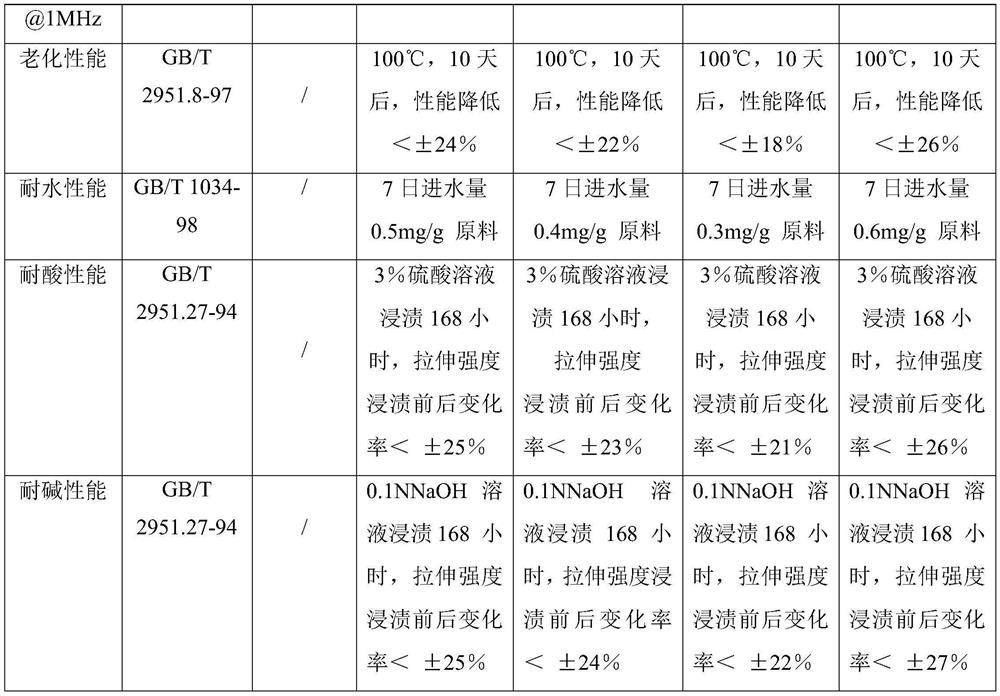

Embodiment 1

[0022] A wear-resistant, anti-oxidation, anti-seepage water photoelectric hybrid cable, which includes an outer protective layer and a rat-proof layer, the rat-proof layer covers the outer surface of the outer protective layer, the preparation of the rat-proof photoelectric hybrid cable Proceed as follows:

[0023] S1: 18 parts of linear low density polyethylene, 6 parts of barium sulfate, 3 parts of high wear-resistant carbon black, 1 part of 2,6-di-tert-butyl-4-methylphenol, and 4 parts of calcium carbonate were ground simultaneously to obtain Mixture A;

[0024] S2: Put the mixture A into the internal mixer, then add 1.3 parts of polyether modified silicone oil, 6 parts of barium sulfate and knead at 161°C for 30 minutes to obtain the mixture B;

[0025] S3: Covering the compound B on the compound cable core through thermoplastic extrusion while it is hot to obtain an outer protective layer;

[0026] S4: Put 5 parts of barium sulfate and 6 parts of diphenoxylate into the ...

Embodiment 2

[0031] A wear-resistant, anti-oxidation, anti-seepage water photoelectric hybrid cable, which includes an outer protective layer and a rat-proof layer, the rat-proof layer covers the outer surface of the outer protective layer, the preparation of the rat-proof photoelectric hybrid cable Proceed as follows:

[0032] S1: Grind 19 parts of linear low density polyethylene, 8 parts of barium sulfate, 4 parts of high wear-resistant carbon black, 2 parts of 2,6-di-tert-butyl-4-methylphenol, and 4 parts of calcium carbonate at the same time to obtain Mixture A;

[0033] S2: Put the mixture A into the internal mixer, then add 1.5 parts of polyether modified silicone oil, 7 parts of barium sulfate and knead at 161°C for 30 minutes to obtain the mixture B;

[0034] S3: Covering the compound B on the compound cable core through thermoplastic extrusion while it is hot to obtain an outer protective layer;

[0035] S4: put 6 parts of barium sulfate and 7 parts of diphenoxylate into the bal...

Embodiment 3

[0040] A wear-resistant, anti-oxidation, anti-seepage water photoelectric hybrid cable, which includes an outer protective layer and a rat-proof layer, the rat-proof layer covers the outer surface of the outer protective layer, the preparation of the rat-proof photoelectric hybrid cable Proceed as follows:

[0041] S1: Grind 20 parts of linear low density polyethylene, 8 parts of barium sulfate, 4 parts of high wear-resistant carbon black, 2 parts of 2,6-di-tert-butyl-4-methylphenol, and 5 parts of calcium carbonate at the same time to obtain Mixture A;

[0042] S2: Put the mixture A into the internal mixer, then add 2.1 parts of polyether modified silicone oil, 8 parts of barium sulfate and knead at 161°C for 30 minutes to obtain the mixture B;

[0043] S3: Covering the compound B on the compound cable core through thermoplastic extrusion while it is hot to obtain an outer protective layer;

[0044] S4: put 7 parts of barium sulfate and 8 parts of diphenoxylate into the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com