Light absorbing material and preparation method thereof

A light-absorbing material and crystal structure technology, applied in chemical instruments and methods, other chemical processes, manganese compounds, etc., can solve problems such as difficult control, high cost of spinel transition oxide powder, and complicated preparation process, and achieve Short production cycle, improved light absorption performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A light-absorbing material, the chemical composition formula is CuMn 2 O 4 . DETAILED prepared as follows:

[0028] Molar ratio of the metal element 1: Weigh 2 CuO (15.910g), MnO 2 (34.776g) powder; sphere: material: water mass ratio (g / g) 2: 1: 3, respectively, bead milling, and the raw material ultra pure water was poured into a ball mill jar; the mill pot is placed on a ball mill station first milling for 1 hour, the rotation speed of 300r / min, then suspended 10min, a ball mill as a period, over 10min after milling for 1 hour, the rotation speed of 300r / min, in total powder mixture was ball milled for 5 hours; then milled the resulting powder mixture was dried, milled; and then the mixture powder was calcined at 800 ℃ warmed to grinding in a box resistance furnace in an air atmosphere, heating rate of 3 ℃ / min, the calcination time is 2 hours, after calcination furnace cooling to room temperature , you can get CuMn 2 O 4 A light absorbing material.

[00...

Embodiment 2

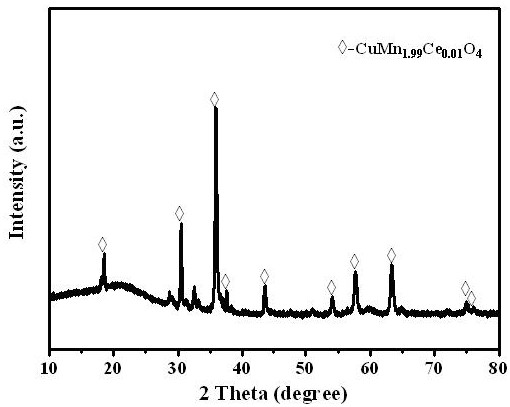

[0030] Example 2 A light absorbing material embodiment, the chemical composition formula CuMn 1.99 CE 0.01 O 4 . DETAILED prepared as follows:

[0031] Molar ratio of the metal element 1: 1.99: 0.01 Weigh CuO (15.910g), MnO 2 (34.602g), CeO 2 (0.344 g) powder; sphere: material: water mass ratio (g / g) 4: 1: 3, respectively, bead milling, and the raw material ultra pure water was poured into a ball mill jar; the mill pot is placed on a ball mill station first milling for 1 hour, the rotation speed of 450r / min, then suspended 10min, a ball mill as a period, over 10min after milling for 1 hour, the rotation speed of 450r / min, a total of 7 hours to give a mixed powder milling; then milled the resulting powder mixture was dried, milled; mixture was then milled powder was heated to 1100 ℃ calcined in a box furnace in an air atmosphere resistance heating rate of 5 ℃ / min, the calcination time was 5 hours, after calcination air quench cooling to room temperature , you can get CuMn 1...

Embodiment 3

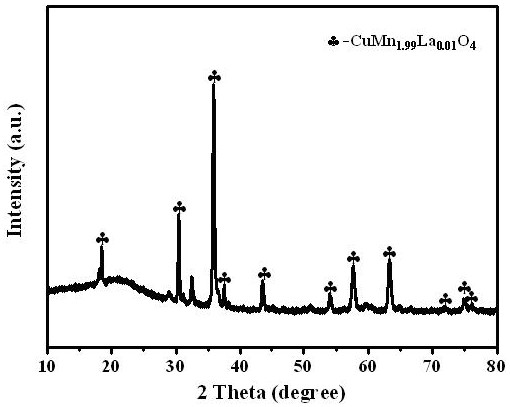

[0034] Example 3 A light absorbing material embodiment, the chemical composition formula CuMn 1.99 La 0.01 O 4 . DETAILED prepared as follows:

[0035] Molar ratio of the metal element 1: 1.99: 0.01 Weigh CuO (15.910g), MnO 2 (34.602g), La 2 O 3(0.326 g) powder; sphere: material: water mass ratio (g / g) 4: 1: 3, respectively, bead milling, and the raw material ultra pure water was poured into a ball mill jar; the mill pot is placed on a ball mill station first milling for 1 hour, the rotation speed of 350r / min, then suspended 10min, a ball mill as a period, over 10min after milling for 1 hour, the rotation speed of 350r / min, a total mixed powder was ball milled for 12 hours; then milled the resulting powder mixture was dried, milled; mixture was then milled powder was heated to 1100 ℃ calcined in a box furnace in an air atmosphere resistance heating rate of 3 ℃ / min, the calcination time was 6 hours, after calcination furnace cooling to room temperature , you can get CuMn 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com