Thermal barrier coating with composite double-ceramic-layer structure and preparation method thereof

A technology of thermal barrier coatings and composite ceramics, applied in coatings, metal material coating processes, fusion spraying, etc., can solve problems such as poor resistance to crack growth, failure, safety of hot end components, and service life hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

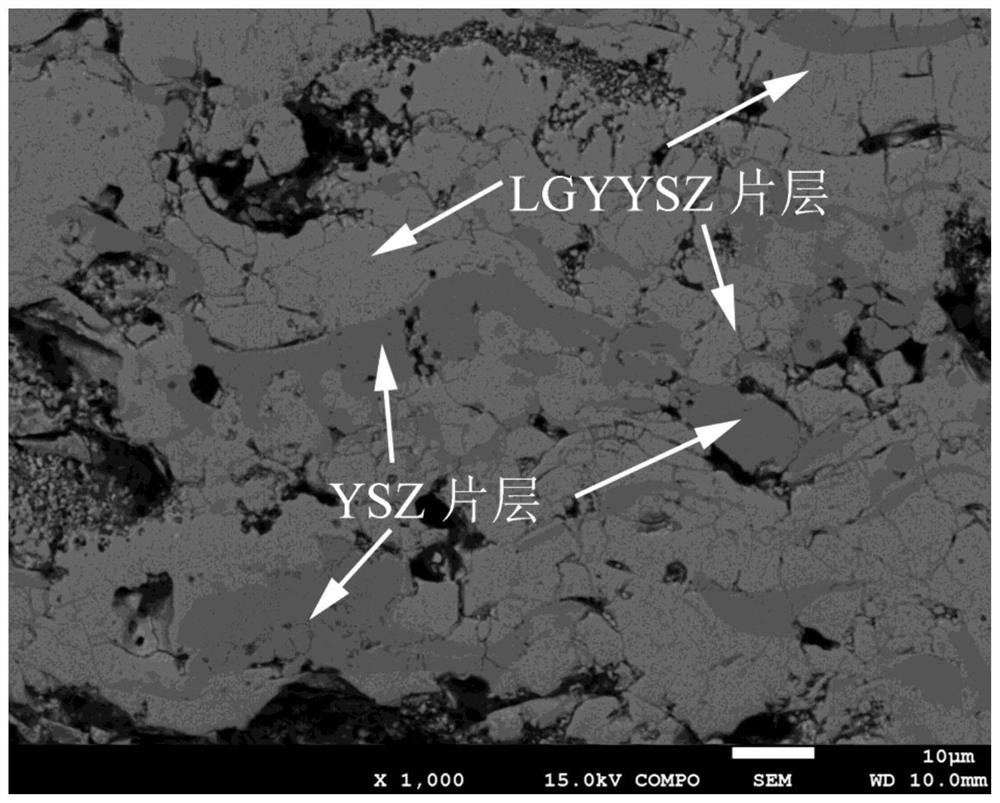

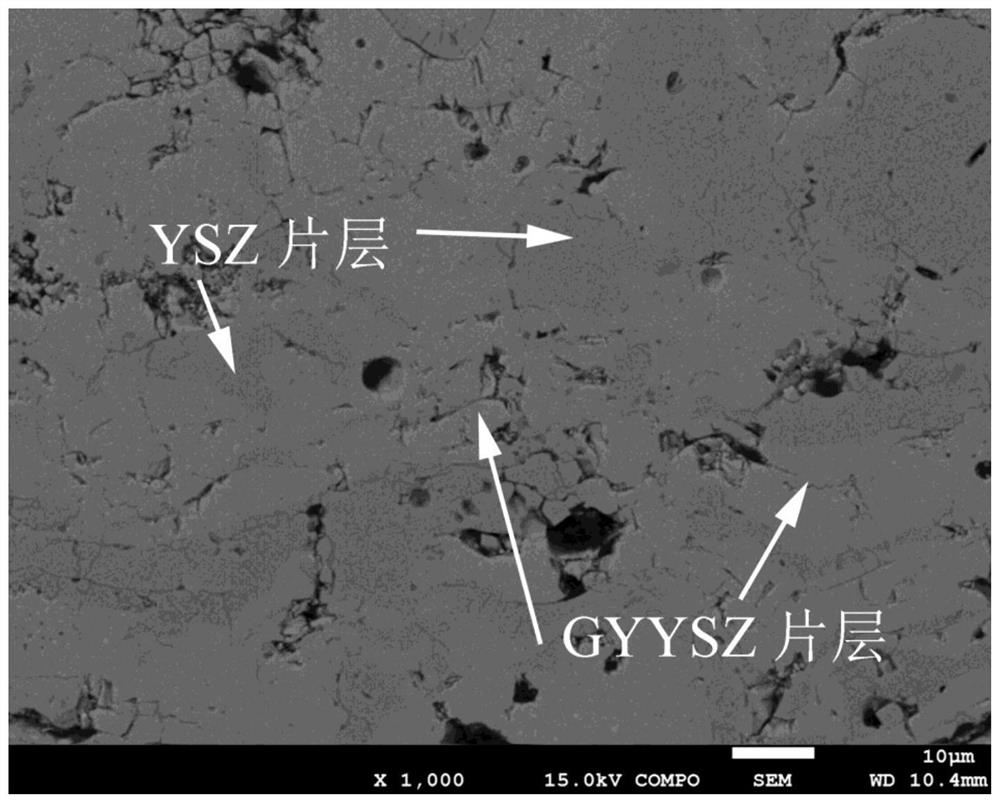

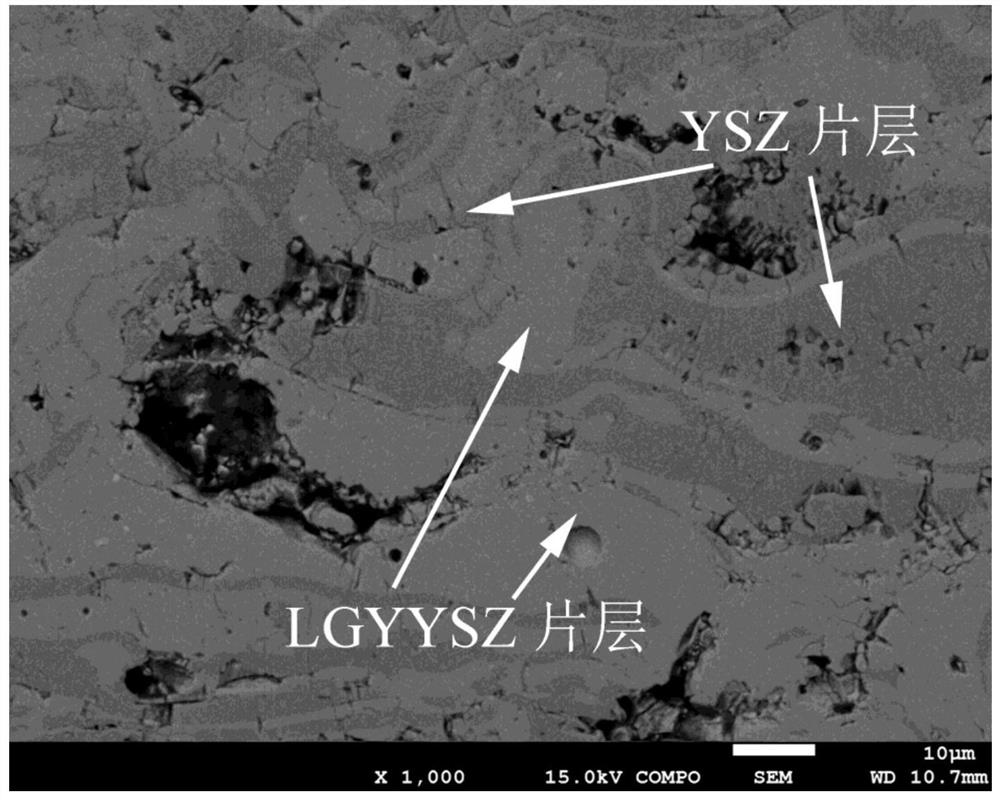

Image

Examples

Embodiment 1

[0048] (1) Ultrasonic cleaning is performed on the surface of the GH2747 superalloy substrate to remove carbon deposits and oil stains on the surface of the substrate, and the surface of the substrate is roughened by sandblasting.

[0049] (2) Adopting the method of plasma spraying, spraying NiCoCrAlY powder on the surface of the superalloy substrate after sandblasting roughening treatment, forms thermal barrier coating bonding layer;

[0050] The specific parameters of plasma spraying are: the spraying distance is 80mm, the current is 580A, the flow rate of argon gas is 120SCFH, the flow rate of helium gas is 10SCFH, the powder feeding rate is 3rpm, the moving speed of the spray gun is 500mm / s, the thermal barrier coating bonding layer The thickness is 0.11mm;

[0051] (3) adopt the method for plasma spraying, spray nanometer YSZ powder on the bonding layer of thermal barrier coating, form nanometer YSZ ceramic layer;

[0052] The specific parameters of plasma spraying are: ...

Embodiment 2

[0064] (1) Ultrasonic cleaning is performed on the surface of the GH2747 superalloy substrate to remove carbon deposits and oil stains on the surface of the substrate, and the surface of the substrate is roughened by sandblasting.

[0065] (2) Adopting the method of plasma spraying, spraying NiCoCrAlY powder on the surface of the superalloy substrate after sandblasting roughening treatment, forms thermal barrier coating bonding layer;

[0066] The specific parameters of plasma spraying are: the spraying distance is 80mm, the current is 580A, the flow rate of argon gas is 120SCFH, the flow rate of helium gas is 10SCFH, the powder feeding rate is 3rpm, the moving speed of the spray gun is 500mm / s, the thermal barrier coating bonding layer The thickness is 0.12mm;

[0067] (3) adopt the method for plasma spraying, spray nanometer YSZ powder on the bonding layer of thermal barrier coating, form nanometer YSZ ceramic layer;

[0068] The specific parameters of plasma spraying are: ...

Embodiment 3

[0080] (1) Ultrasonic cleaning is performed on the surface of the GH2747 superalloy substrate to remove carbon deposits and oil stains on the surface of the substrate, and the surface of the substrate is roughened by sandblasting.

[0081] (2) Adopting the method of plasma spraying, spraying NiCoCrAlY powder on the surface of the superalloy substrate after sandblasting roughening treatment, forms thermal barrier coating bonding layer;

[0082] The specific parameters of plasma spraying are: the spraying distance is 80mm, the current is 580A, the flow rate of argon gas is 120SCFH, the flow rate of helium gas is 10SCFH, the powder feeding rate is 3rpm, the moving speed of the spray gun is 500mm / s, the thermal barrier coating bonding layer The thickness is 0.13mm;

[0083] (3) adopt the method for plasma spraying, spray nanometer YSZ powder on the bonding layer of thermal barrier coating, form nanometer YSZ ceramic layer;

[0084] The specific parameters of plasma spraying are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com