High-CTI brominated flame-retardant reinforced polyamide composite material and preparation method and application thereof

A brominated flame retardant and composite material technology, applied in the field of polyamide resin modification, can solve the problem that the synergistic effect of brominated flame retardants and halogen-free flame retardants is not good, and the thermal stability of halogen-free flame retardants cannot be eliminated. , increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

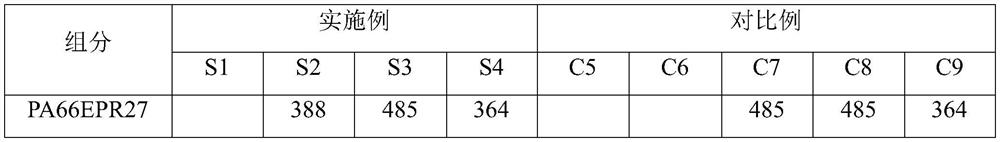

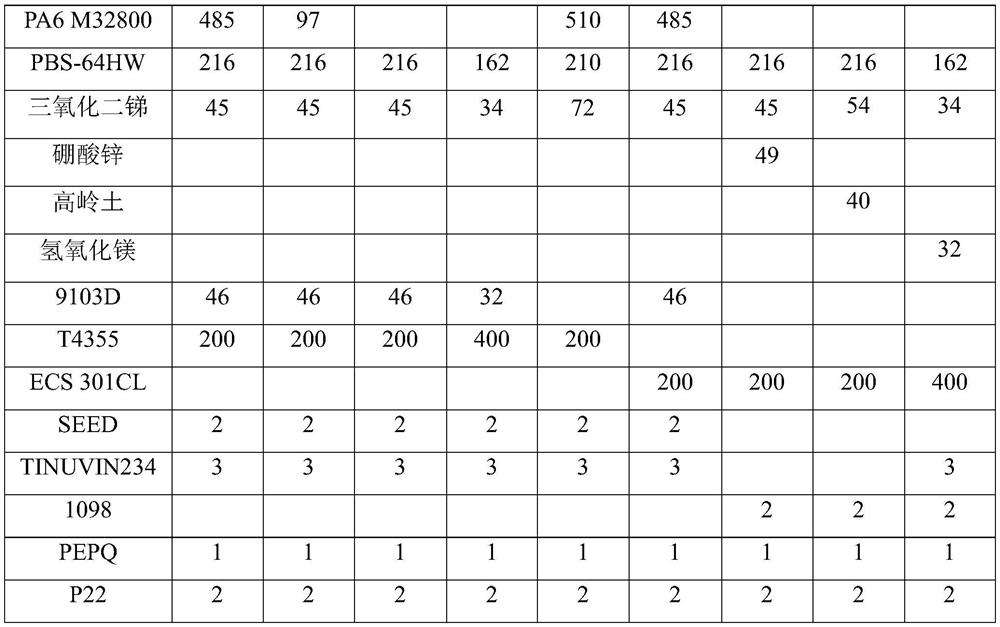

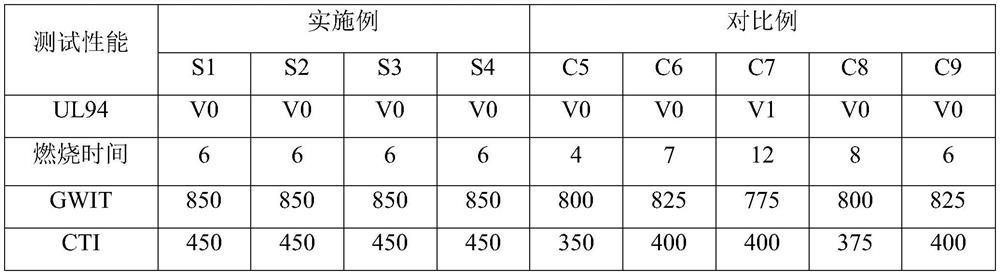

[0037] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0038] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention, especially are not limited to the model of each component raw material used in the following specific examples.

[0039] Materials and models used in the embodiment:

[0040] PA66 resin: PA66 EPR27, Pingdingshan Shenma;

[0041] PA6 resin: PA6 M32800, Guangdong Xinhui Meida;

[0042] Brominated flame retardant: polybrominated styrene PBS-64HW, Great Lakes;

[0043] Antimony trioxide: commercially available;

[0044] Talc powder: Cimtuff9103D;

[0045] Flat glass fiber: TFG-3.0-T4355;

[0046] Chopped glass fiber: ECS 301CL, Chongqing International Composite Materials Co., Ltd.;

[0047] Hindered amine antioxidant: Clariant S-EED;

[0048] Phosphite antioxidant: C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com