A kind of preparation method and application of modified hnts supported tin-based catalyst

A catalyst, tin-based technology, applied in the field of preparation of modified HNTs supported tin-based catalysts, can solve the problems of limiting the application of polycaprolactone, impact, and insufficient thermal stability, and achieve the effect of improving the scope and degree of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] An embodiment of the present invention provides a method for preparing a modified HNTs-supported tin-based catalyst, with reference to Figure 8, which mainly includes the following steps:

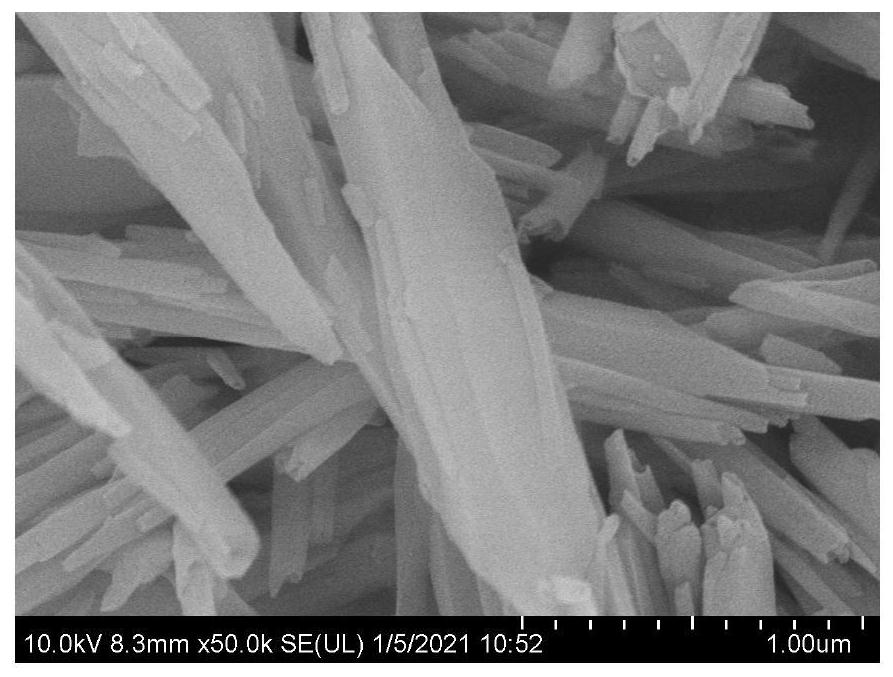

[0032] S1, the stannous chloride (SnCl 2 ) and halloysite nanotubes (HNTs) were added to toluene, and stirred uniformly to obtain a first mixture, wherein, in parts by weight, the first mixture included 100 parts of toluene, 5-12 parts of halloysite nanotubes, 0.4-1.3 parts of stannous chloride; based on the natural multi-walled microtubule structure of HNTs, HNTs can act as a solid carrier when the monomer catalyzes polymerization. The active sites are enhanced by loading stannous chloride onto the inner and outer surfaces of the modified HNTs by physical force;

[0033] S2. Add silane coupling agent KH-550 (APTES) into toluene, stir evenly to obtain a second mixture, wherein, in parts by weight, the mixed solution includes 100 parts of toluene and 1-3 parts of silane coupling agen...

Embodiment 1

[0041] A preparation method of a modified HNTs-supported tin-based catalyst, which mainly comprises the following steps:

[0042] S1, the stannous chloride (SnCl 2 ) and halloysite nanotubes (HNTs) were added into toluene, and stirred uniformly to obtain a first mixture, wherein, in parts by weight, the first mixture included 100 parts of toluene, 8.2 parts of halloysite nanotubes, chlorinated 0.7 parts of tin;

[0043] S2, adding silane coupling agent KH-550 (APTES) into toluene, stirring evenly to obtain a second mixture, wherein, in parts by weight, the mixed solution includes 100 parts of toluene and 1.7 parts of silane coupling agent;

[0044] S3, with n((SnCl 2 ):n(APTES)=1:1 Add the second mixture prepared by S2 to the first mixture prepared by S1 to obtain the third mixture, and apply three nitrogen purge cycles, stir for 15h, stirring speed 500r / min , the modified HNTs-supported tin-based catalyst (APTES-P-HNTs-SnCl 2 ).

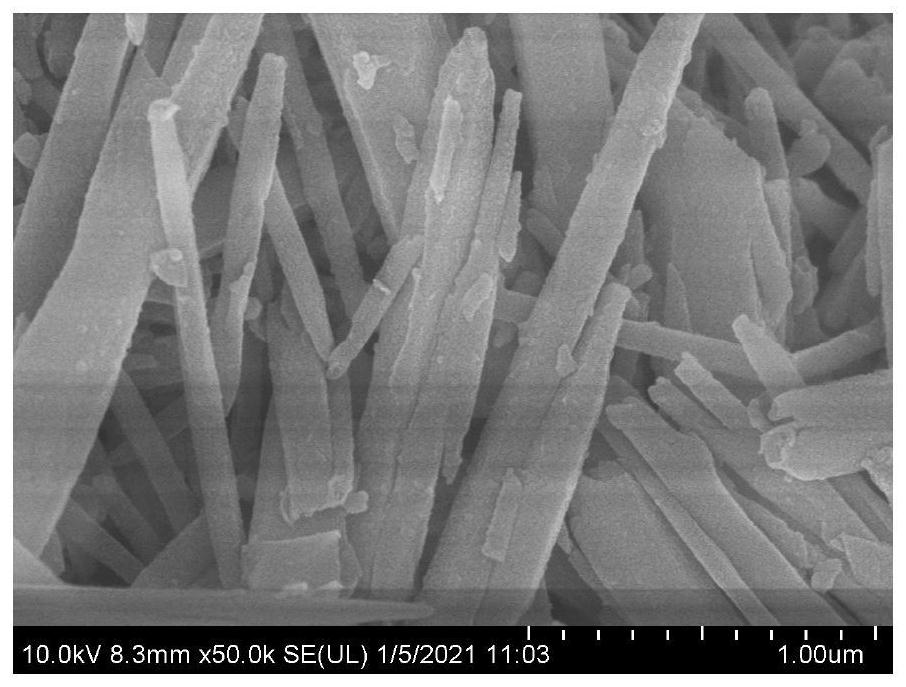

[0045] Taking the halloysite nanotubes i...

Embodiment 2

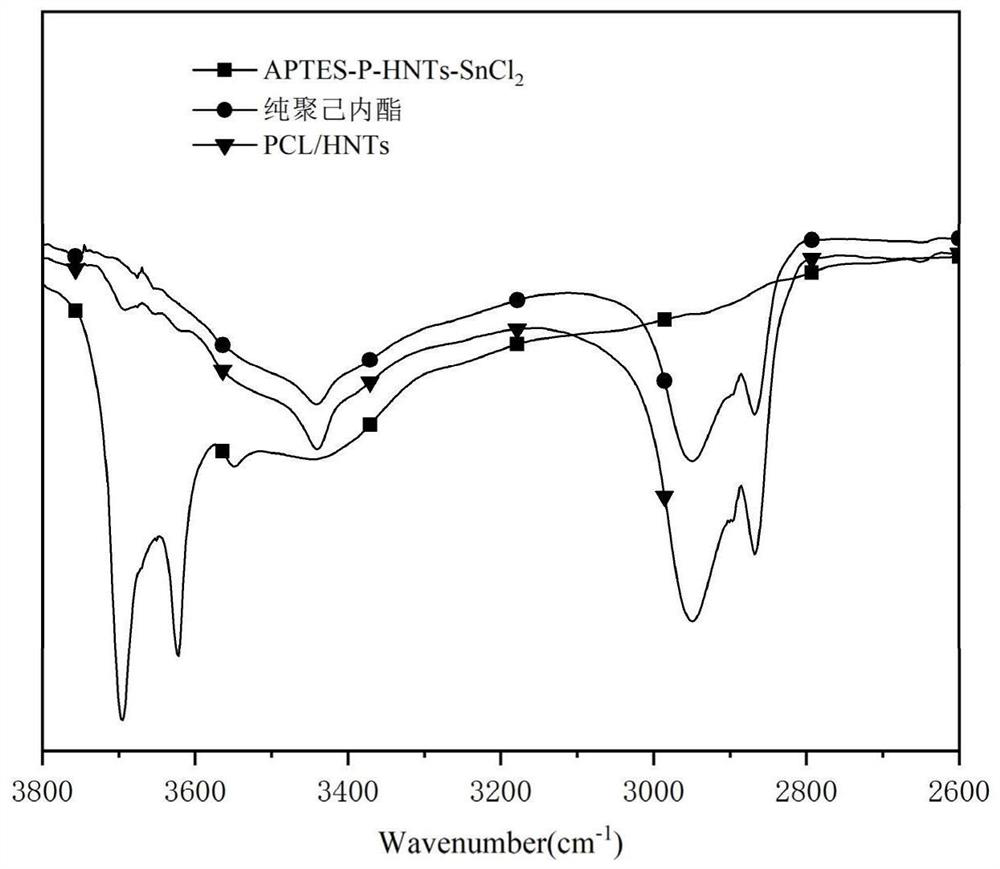

[0051] S1. The modified HNTs supported tin-based catalyst and ε-caprolactone prepared in Example 1 were mixed with a mass ratio m(APTES-P-HNTs-SnCl 2 ):m(ε-caprolactone)=1:100 ratio, put it into the reaction flask to form a mixture, add magnetron into the mixture, carry out end-capping operation after evacuating for 45min, and then put it into an oil bath, Start the magnetic stirrer and perform magnetic stirring to obtain the product, wherein the stirring speed is 500r / min, and after rising from room temperature to 150°C, the temperature is kept constant for 24h;

[0052] S2. Add dichloromethane to the product to completely dissolve the product, and finally add methanol to precipitate the product, stand, filter and dry to obtain PCL / HNTs with a yield of 92.4% and a number average molecular weight of 28190. Wherein, in terms of weight ratio, product:dichloromethane:methanol=1:2.65:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com