High-strength high-temperature acid fracturing temporary plugging agent and preparation method and application thereof

A high-strength, temporary plugging agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of low pressure bearing strength of temporary plugging agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of high-strength high-temperature acid fracturing temporary plugging agent containing inorganic salts in different proportions

[0049] (1) Mixing: Weigh 300g of polyvinyl alcohol, 250g of polylactic acid, 0.2g of neopentyl glycol, 0.1g of pentaerythritol, 0.2g of triethanolamine, inorganic salt (prepared according to the proportioning in Table 1), chitosan 1.0 g, 0.5g of silane coupling agent KH550, 5.0g of starch binder and 0.5g of antioxidant 1010, mixed uniformly, dried at 80°C for 3h to remove residual trace moisture in the material, and then cooled to room temperature in a desiccator to obtain mixture;

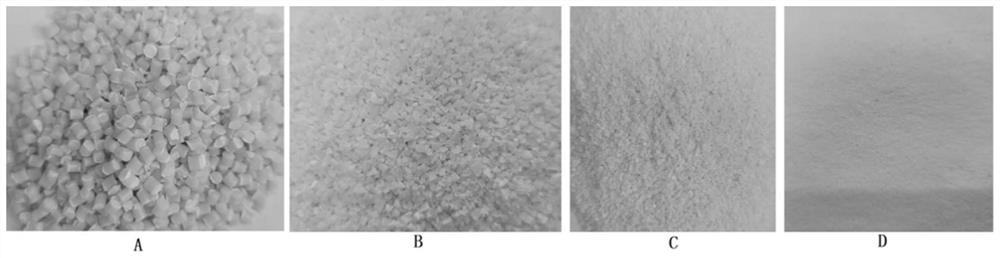

[0050] (2) Extrusion granulation: Put the mixture obtained in step (1) into the SJZS-10B miniature twin-screw extruder for melting and plasticization, extrude the melted and plasticized material to form an extruded strip, and the temperature for melting and extrusion is 180 -190°C, the melt extrusion time is 50-60s; the extruded strips are c...

Embodiment 2

[0058] Example 2 Preparation of high-strength, high-temperature acid fracturing temporary plugging agent containing composite plasticizers in different proportions

[0059] (1) Mixing materials: take polyvinyl alcohol 300g, polylactic acid 250g, composite plasticizer (prepared by the proportioning in Table 2), sodium chloride 50g, potassium chloride 50g, sodium carbonate 20g, calcium carbonate 60g, Chitosan 0.2g, silane coupling agent KH550 0.5g, starch binder 5.0g and antioxidant 1010 0.5g, mix evenly, dry at 90°C for 2h, remove residual trace moisture in the material, then cool in a desiccator To room temperature to obtain the mixture; Steps (2), (3) are the same as in Example 1. And the processing performance of the prepared temporary plugging agent was tested. The results are shown in Table 2.

[0060] Table 2 Effects of different proportions of composite plasticizers on the processing performance of temporary plugging agents

[0061]

[0062] It can be seen from the...

Embodiment 3

[0063] Example 3 Preparation of high-strength high-temperature acid fracturing temporary plugging agents with different meshes

[0064] (1) Mixing: Weigh 200g of polyvinyl alcohol, 400g of polylactic acid, 0.1g of neopentyl glycol, 0.5g of pentaerythritol, 0.2g of triethanolamine, inorganic salt (prepared according to the proportioning in Table 3), chitosan 0.5 g. 0.2g of silane coupling agent KH560, 2.0g of starch binder and 0.2g of antioxidant 168, mixed evenly, dried at 85°C for 2.5h to remove residual trace moisture in the material, and then cooled to room temperature in a desiccator get the mixture;

[0065] (2) Extrusion granulation: put the mixture obtained in step (1) into the SJZS-10B miniature twin-screw extruder for melting and plasticization, and extrude the melted and plasticized material to form an extruded strip, and the temperature for melting and extrusion is 180- 220°C; melt extrusion time is 100-110S, the extruded strips are cooled to room temperature by SF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com