Chamfering machine

A chamfering machine and chamfering technology, which is applied in the field of chamfering machines, can solve the problems of unstable grinding wheel grinding and silicon wafer grinding effect, and achieve the effects of convenient chamfering and grinding process, improving work efficiency and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

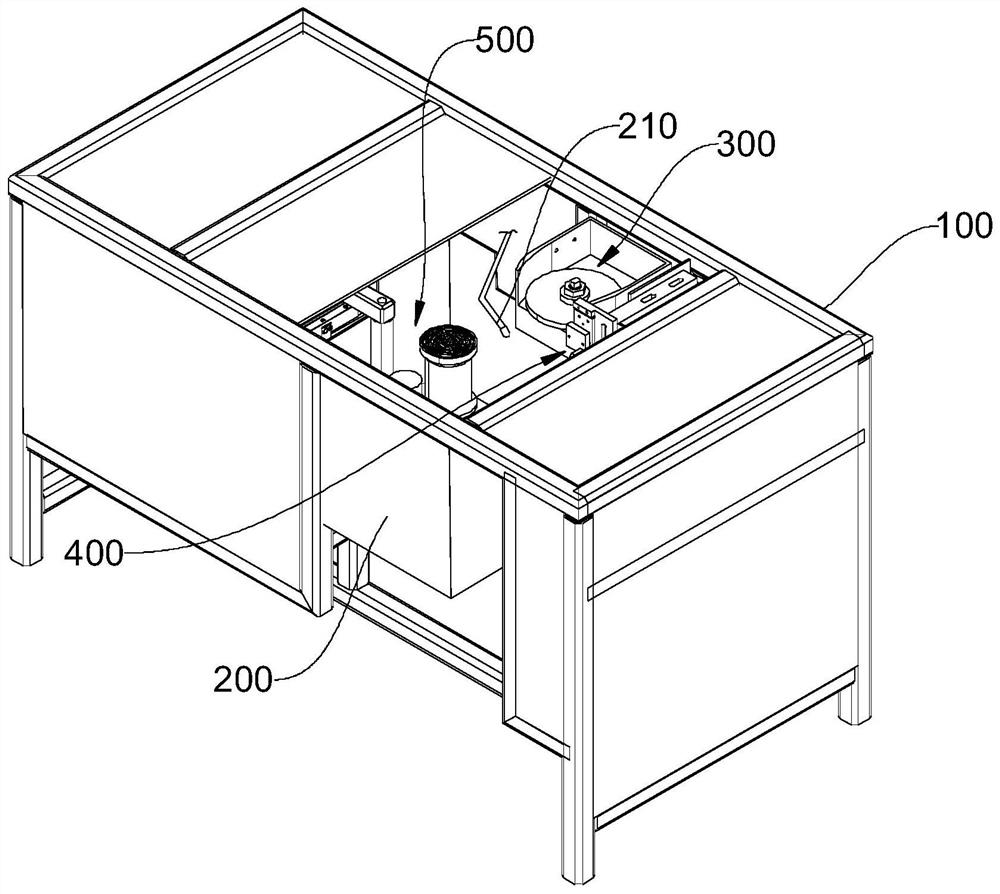

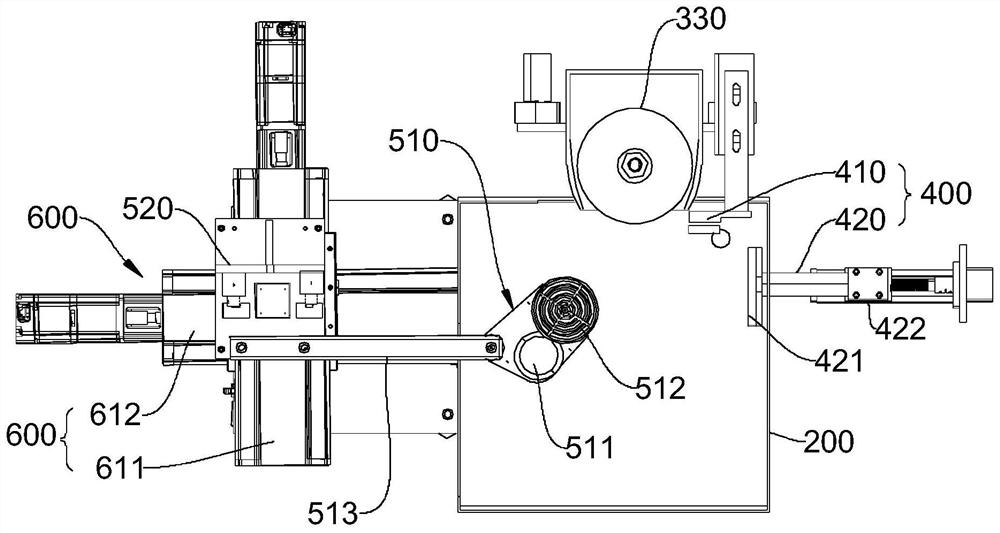

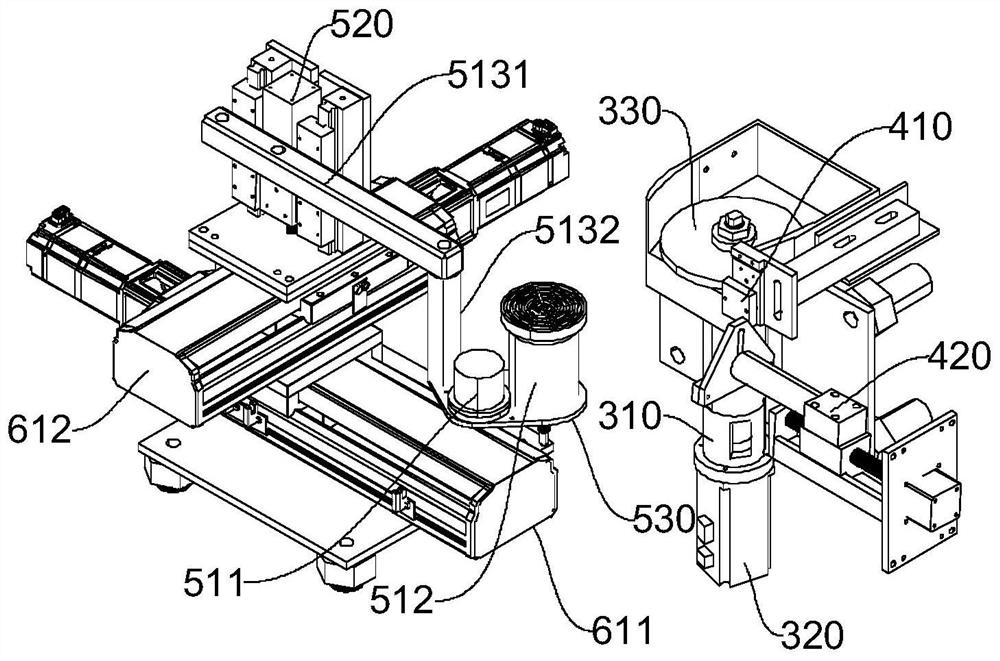

[0033] Please refer to Figure 1 to Figure 5, as shown in this embodiment, a chamfering machine is provided, which includes a frame 100, a working box 200, a chamfering assembly 300, a centering assembly 400, an object loading assembly 500 and a sliding assembly 600 are arranged in the frame 100; The box 200 is used to provide installation stations for some components and to collect debris generated when polishing silicon wafers, making the collection and processing of silicon chips more convenient. The working box 200 is a rectangular box; the chamfering component 300 is installed in the working box 200 The outer wall is between the frame 100 and the outer wall of the working box 200, which makes the maintenance of the chamfering assembly 300 more convenient, and also prevents silicon chips from entering the structure of the chamfering assembly 300, causing damage to the chamfering assembly 300; The object assembly 500 includes an object stage 510 and an elevating table 520 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com