Cement bag breaker for construction work

A technology of building construction and bag breaking machine, which is applied in loading/unloading, packaging, cutting and unsealing, etc., which can solve troublesome problems and achieve the effect of convenient collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

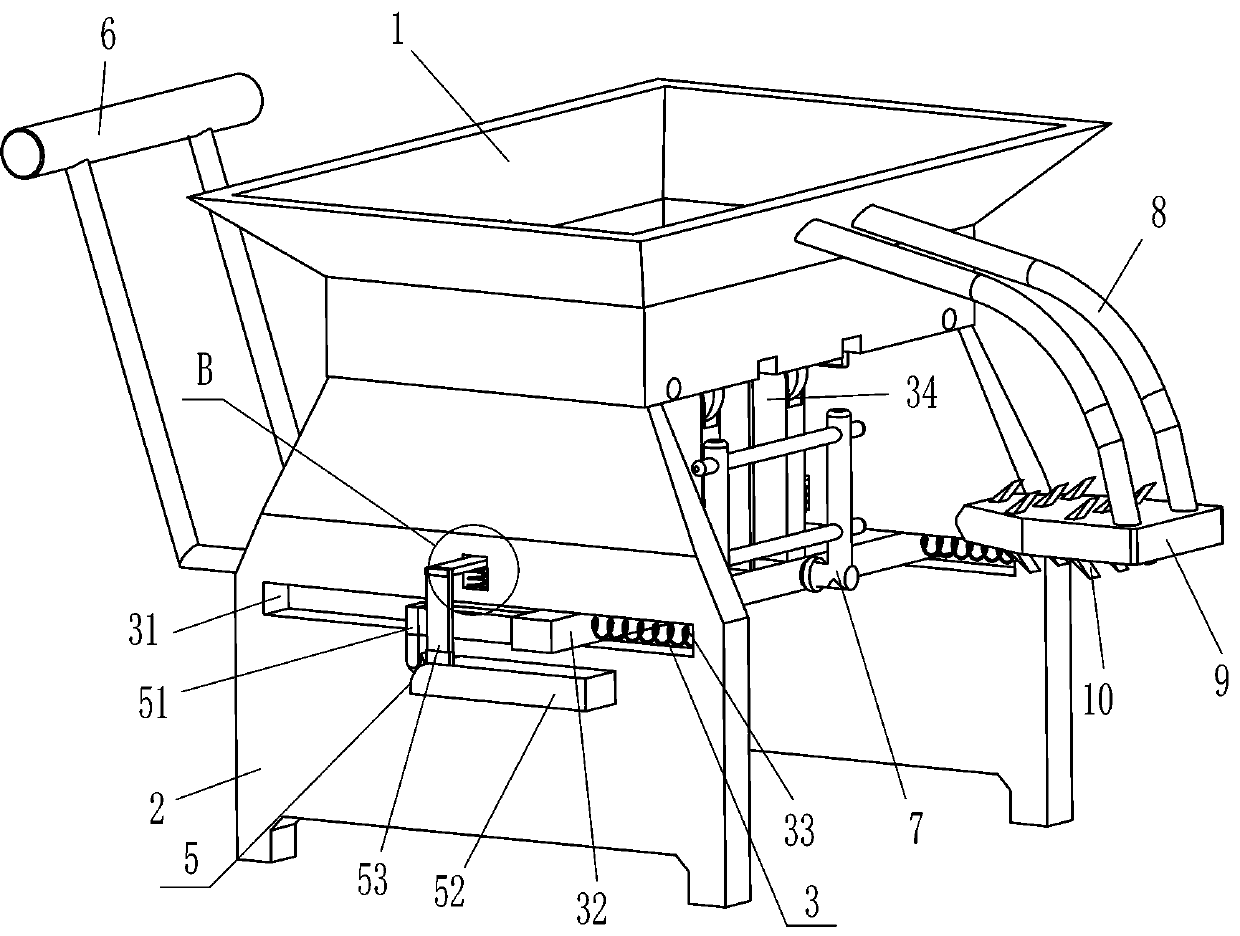

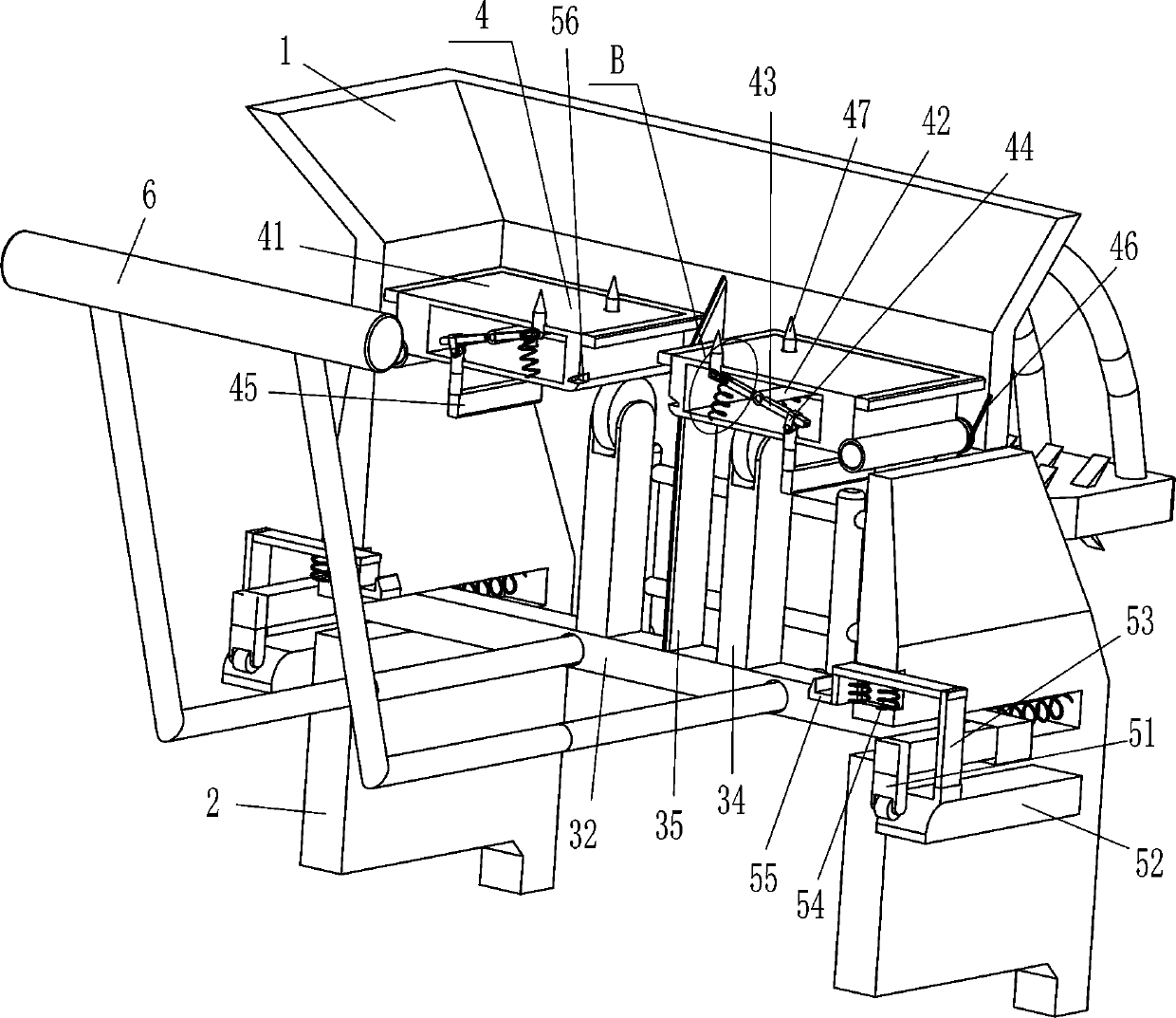

[0023] see Figure 1-Figure 3 , a cement bag breaking machine for building construction, comprising a placement frame 1, a support plate 2, a support cutting mechanism 3 and a swing mechanism 4, the support plate 2 is fixedly connected to the front and rear sides of the bottom of the placement frame 1, and the front and rear support plates A support cutting mechanism 3 is arranged between the two, and a swing mechanism 4 for placing the cement bag is provided in the placing frame 1, and the swing mechanism 4 contacts and cooperates with the support cutting mechanism 3.

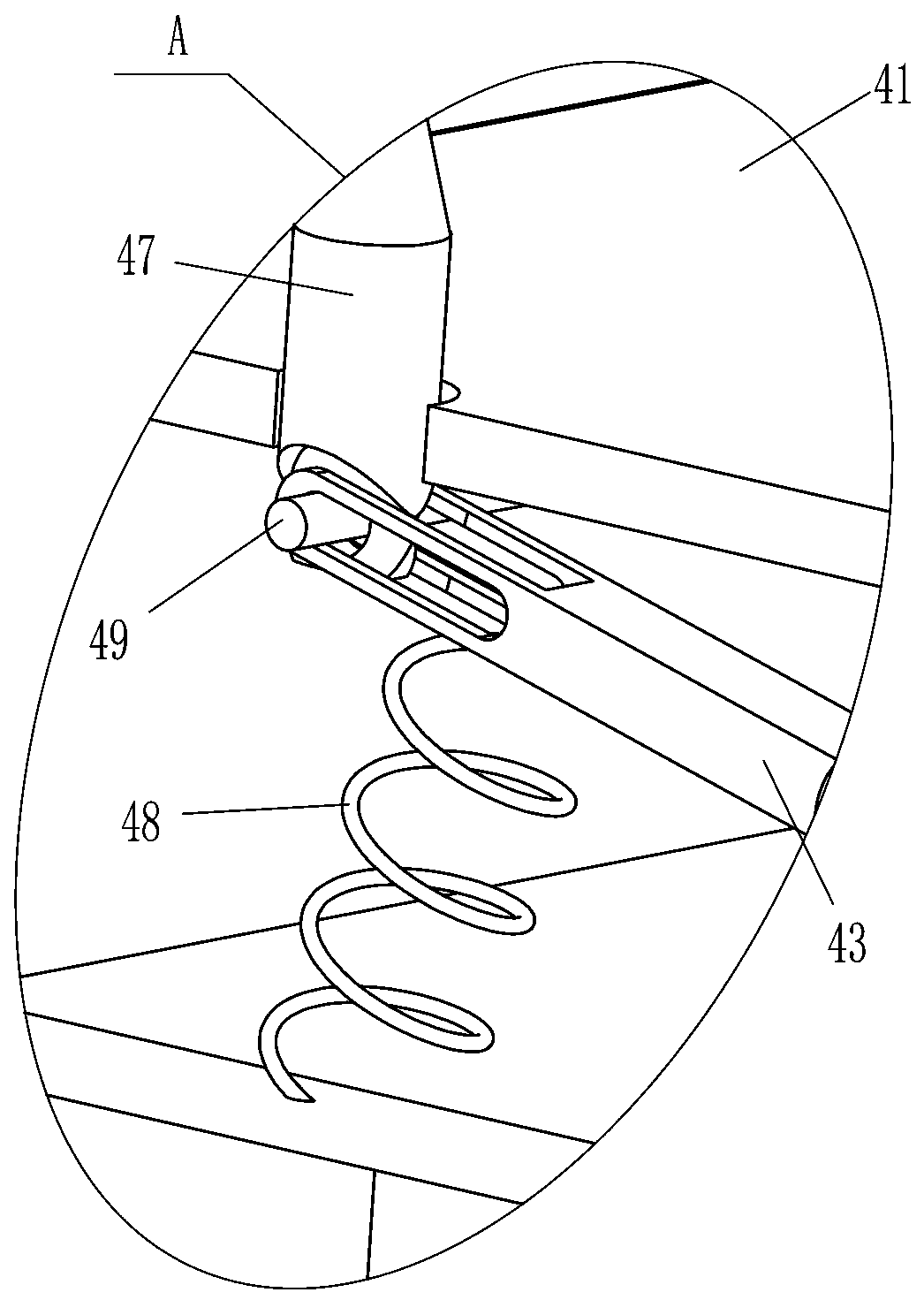

[0024] Support cutting mechanism 3 comprises slide plate 32, first spring 33, support wheel 34 and cutter 35, all has chute 31 in the middle part of support plate 2 of front and rear sides, between the chute 31 of front and back sides, sliding type is provided with Sliding plate 32, the front and rear sides on the right side of sliding plate 32 are respectively connected with the first spring 33 between the fr...

Embodiment 2

[0030] see figure 1 , figure 2 with Figure 4 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a clamping mechanism 5 is also included, and the clamping mechanism 5 includes a contact wheel 51, a trigger block 52, an L-shaped plate 53, a third spring 54 and Buckle 55, the upper side of the middle part of the support plate 2 on the front and rear sides is slidingly provided with an L-shaped plate 53, and two third springs 54 are connected between the inner top of the L-shaped plate 53 and the inside of the support plate 2, and the L-shaped plate 53 The bottom end is fixedly connected with a trigger block 52, the upper left side of the trigger block 52 is an arc surface, the inner ends of the L-shaped plates 53 on the front and rear sides are fixedly connected with buckles 55, and the front side hollow frame 41 is connected to the middle part of the outer rear side and the rear side hollow frame. The middle part of the outer front...

Embodiment 3

[0033] see figure 1 with figure 2 The main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, an L-shaped tie rod 6 and a fixed frame 7 are also included, and an L-shaped tie rod is provided for sliding between the front and rear parts of the sliding plate 32. 6. Between the two ends on the right side of the L-shaped pull rod 6, there is a fixed frame 7 that can push the cement bag.

[0034] Also includes arc rod 8, fixed plate 9 and limit block 10, two arc rods 8 are affixed to the upper side of the middle part of the outer right side of the placement frame 1, and two arc rods 8 bottom ends are affixed with The fixed plate 9 that can make cement bag place, fixed plate 9 tops and the bottom all evenly spaced are affixed with the spacer block 10 that can cement bag be fixed.

[0035] When a bag of cement was put into the placement frame 1, the operator could pull the L-shaped pull rod 6 to drive the slide plate 32 to move to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com