Digital controlling method for communicating structure of short-circuit transient COz weld

A technology of short-circuit transition and communication structure, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of difficult multi-task structure time juxtaposition, complicated circuits, and difficult real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

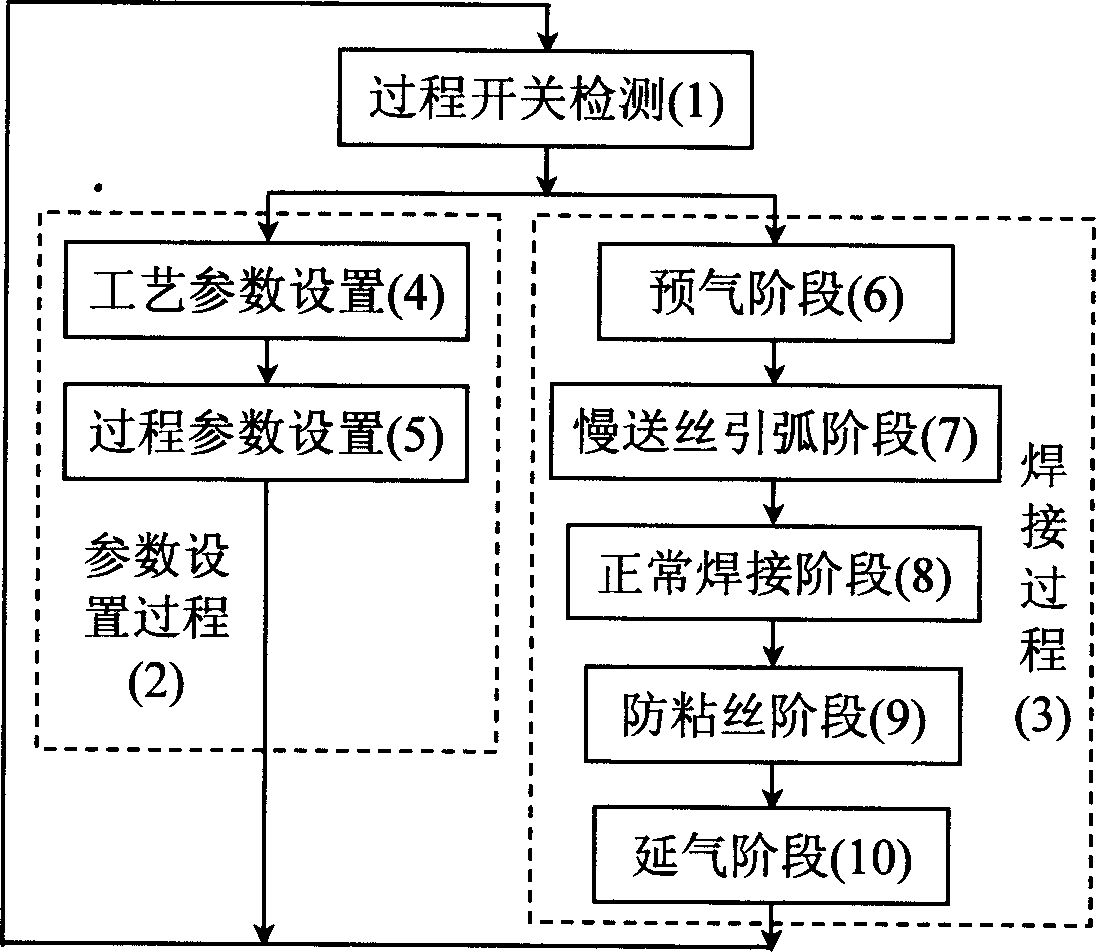

[0023] 1. Process parameter setting (through 5 process selection switches on the welding power panel):

[0024] ① Welding method selection switch CO 2 / MAG;

[0025] ②Wire material selection switch solid core / flux core;

[0026] ③Wire diameter selection switch 1.2mm / 1.0mm;

[0027] ④ Parameter adjustment mode selection switch unified adjustment / individual adjustment;

[0028] ⑤ Welding current form selection switch pulse welding / DC welding.

[0029] 2. Process parameter setting:

[0030] ① welding voltage 15 ~ 26V;

[0031] ②Welding current 40~350A;

[0032] 3. Technical indicators of welding process completion:

[0033] ①The pre-air time is adjustable from 100ms to 500ms;

[0034] ②The slow wire feeding speed is adjustable from 1 to 2m / min;

[0035] ③ Anti-sticking time 380ms and 100ms;

[0036] ④ The delay time is adjustable from 100ms to 500ms.

[0037] 4. On-site parameter display:

[0038] ①Process parameters;

[0039] ②Process param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com