Method for achieving alternating or pulsed magnetic field action through static magnetic field facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

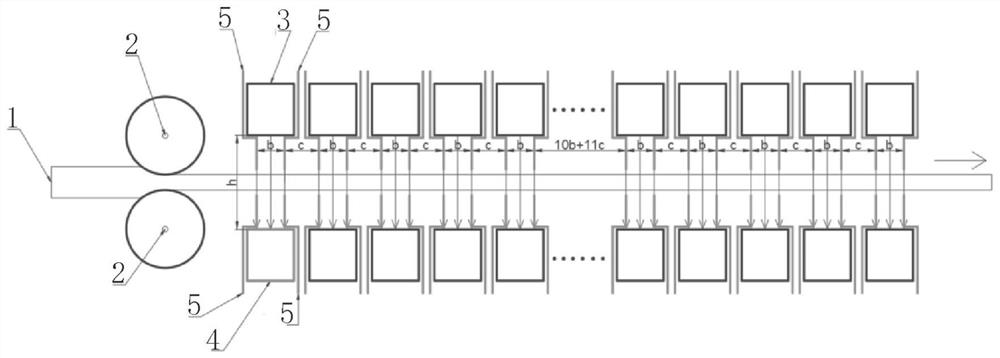

[0041] Taking the copper strip rolling production line as an example, it is known that the continuous rolling speed of the copper strip 1 is 100m / s, and the speed cannot be adjusted; the purpose of the magnetic field treatment is to reduce and homogenize the stress of the rolled copper strip and reduce the shape adjustment. difficulty.

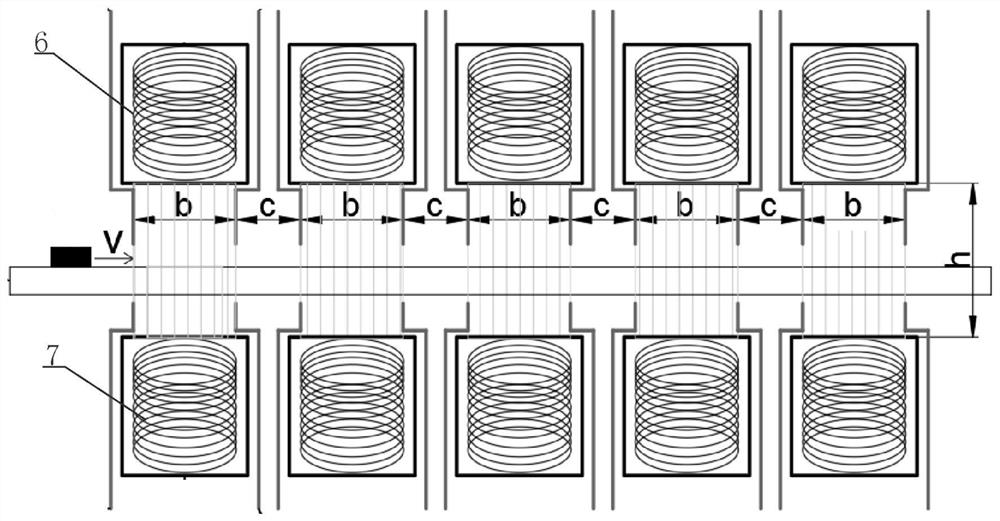

[0042] S1, obtaining the original alternating or pulsed magnetic field waveform and waveform parameters required by the products on the production line with time as the horizontal axis. Specifically, based on theoretical derivation and combined with experimental production experience, the required magnetic field waveform is a unidirectional pulsed magnetic field waveform. Among them, the waveform parameters are: peak magnetic field strength is 0.5T, pulse width is about 5μs, pulse interval is about 25μs, and the total number of pulses The number is 20.

[0043] S2, transforming the original alternating or pulsed magnetic field waveform and wa...

Embodiment 2

[0052] Taking the cemented carbide cutting tool production line as an example, the speed of conveying products in this production line can be adjusted as needed. The purpose of magnetic field treatment is to realize batch pulsed magnetic field treatment of cemented carbide tools, thereby improving the cutting performance and service life of cemented carbide tools. (the following descriptions only describe the differences from Example 1, and those skilled in the art at other similar places can grasp it by conventional technical means)

[0053] According to theoretical derivation and combined with experimental production experience, the required magnetic field waveform is a unidirectional pulsed magnetic field waveform, where the waveform parameters are: peak magnetic field strength is 1.5T, pulse width is about 2μs, pulse interval is about 10μs, and the total number of pulses is 5 indivual.

[0054] The difference between this embodiment and Embodiment 1 is that the peak magne...

Embodiment 3

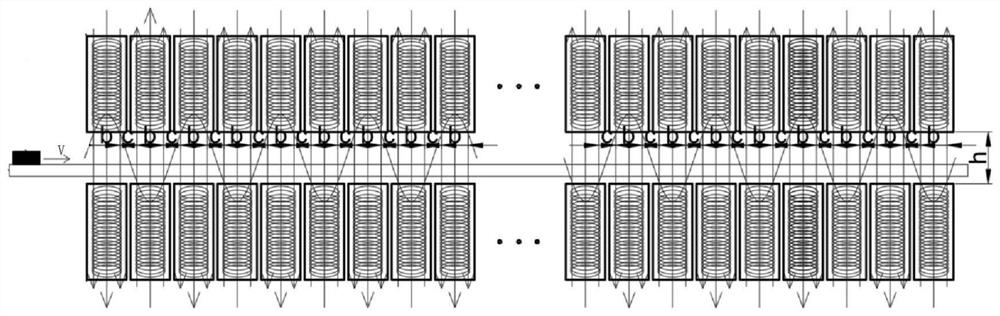

[0060] Taking the titanium alloy blade production line as an example, the conveying speed of the production line can be adjusted; the purpose of the magnetic field treatment is to adjust the microstructure of the parts, optimize the processing stress state, and improve the fatigue life of the titanium alloy blades. (the following descriptions only describe the differences from Example 1, and those skilled in the art at other similar places can grasp it by conventional technical means)

[0061] According to the current magnetic field treatment process, one of the magnetic fields that can be used to improve the fatigue life of titanium alloy blades is an alternating magnetic field with a sinusoidal waveform, where the waveform parameters are: peak magnetic field strength (amplitude) 1.5T, frequency 50Hz, no duty cycle , duration 1s.

[0062] The peak magnetic field strength is 1.5T, and the electromagnetic coil is selected as the static magnetic field facility. The upper electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com