Method for preparing three-dimensional porous graphene sheet by adopting low-temperature double-salt compound and application of three-dimensional porous graphene sheet

A three-dimensional porous, graphene sheet technology, applied in the field of electrochemistry and energy materials, can solve the problems of poor performance of double-layer capacitors, achieve high tap density, good conductivity, and improve the effect of surface loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 200 g of dry coconut shell and place it in a pulverizer for 5 minutes to make it into a powder. The particle size is below 50 µm. Due to the small particle size below 50 µm, it can be evenly mixed and contacted with double salt , increasing the reactivity.

[0044] (2) Take 50 g of crushed coconut shells and place them under an argon atmosphere tube furnace for carbonization. The carbonization temperature is 650 °C, the carbonization time is 3 h, and the heating rate is 5 °C min -1 , naturally cooled to room temperature after carbonization; the heating rate was verified to be 5°C min by experiments -1 , the most suitable, too high a heating rate will affect the formation of carbon, and 650 degrees carbonization for 3 hours, mainly to fully decompose cellulose and hemicellulose.

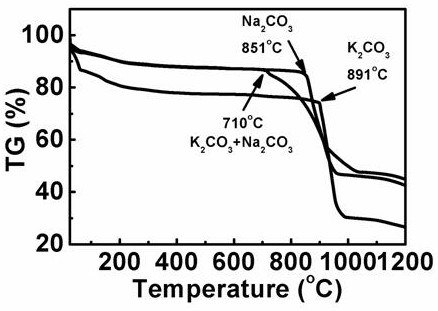

[0045] (3) Combine the carbonized material with K 2 CO 3 and Na 2 CO 3 Mix evenly by mass 1:4, where K 2 CO 3 and Na 2 CO 3 The molar ratio is 0.45:0.55, carbon takes 10 g, K...

Embodiment 2

[0059] (1) Weigh 200 g of dry coconut shell and place it in a pulverizer for 5 min to make it into a powder with a particle size of 50 µm or less.

[0060] (2) Take 50 g of crushed coconut shells and place them under an argon atmosphere tube furnace for carbonization. The carbonization temperature is 650 °C, the carbonization time is 3 h, and the heating rate is 5 °C min -1 , and naturally cooled to room temperature after carbonization.

[0061] (3) Combine the carbonized material with K 2 CO 3 and Na 2 CO 3 Mix evenly by mass 1:4, where K 2 CO 3 and Na 2 CO 3 The molar ratio is 0.45:0.55, carbon takes 10 g, K 2 CO 3 and Na 2 CO 3 Take 20.6507 g and 19.3493 g, respectively.

[0062] (4) The mixed material was activated under a tube furnace in an argon atmosphere. The activation temperature was 1000°C, the activation time was 4h, and the heating rate was 5°C min -1 , and naturally cooled to room temperature after activation.

[0063] (5) Wash the activated materi...

Embodiment 3

[0066]Weigh 200 g of dry coconut shells and place them in a pulverizer for 5 min to make them into powder with a particle size of 50 μm or less.

[0067] (2) Take 50 g of crushed coconut shells and place them under an argon atmosphere tube furnace for carbonization. The carbonization temperature is 650 °C, and the carbonization time is 3 h. The heating rate is 5 °C min -1 , and naturally cooled to room temperature after carbonization.

[0068] (3) Combine the carbonized material with K 2 CO 3 and Na 2 CO 3 Mix evenly by mass 1:4, where K 2 CO 3 and Na 2 CO 3 The molar ratio is 0.45:0.55, the carbon is 10g, K 2 CO 3 and Na 2 CO 3 Take 20.6507 g and 19.3493 g, respectively.

[0069] (4) The mixed material was activated under a tube furnace in an argon atmosphere. The activation temperature was 900°C, the activation time was 4h, and the heating rate was 5°C min -1 , and naturally cooled to room temperature after activation.

[0070] (5) Wash the activated material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com