Preparation method for metal injection molding of titanium alloy composite material

A composite material and injection molding technology, applied in the field of titanium alloy composite metal preparation, can solve the problems of poor preparation quality, complex process equipment and high cost, and achieve the effects of simple and convenient operation, improved strength and toughness, and reduced preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

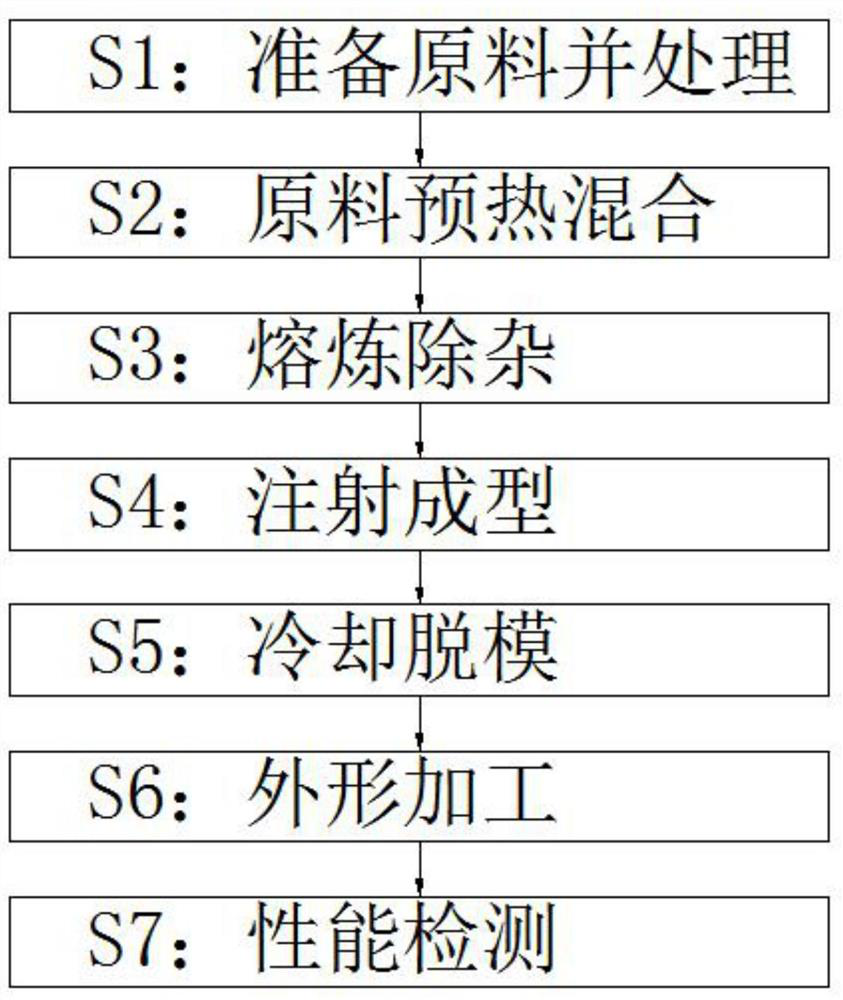

[0037] Refer Figure 1 , A method of preparing a metal injection molding of a titanium alloy composite, including the following preparation steps:

[0038] S1: Prepare raw materials and process;

[0039] S2: Preheating mix;

[0040] S3: Melting is amortized;

[0041] S4: injection molding;

[0042] S5: Cooling and demolding;

[0043] S6: Processing;

[0044] S7: Performance detection.

[0045] In the present embodiment, the material of S1 includes 60 parts of titanium powder, 10 binder, 3 parts of boron carbide powder, 3 aluminum powder, 1 magnesium powder, 1.5 parts of copper powder, 2 Nickel powder, carbon fiber powder 5 0.5 parts of the modifier.

[0046] Preferably, the carbon fiber powder preparation is:

[0047] First, take out the carbon fiber raw material to degenerate, clean, dry treatment;

[0048] Second, and use a crusher to smash and use a 500 mesh filter multiple screening;

[0049] Third, weigh the amount of carbon fiber powder.

[0050] In the present embodiment, th...

Embodiment 2

[0064] Refer Figure 1 , A method of preparing a metal injection molding of a titanium alloy composite, including the following preparation steps:

[0065] S1: Prepare raw materials and process;

[0066] S2: Preheating mix;

[0067] S3: Melting is amortized;

[0068] S4: injection molding;

[0069] S5: Cooling and demolding;

[0070] S6: Processing;

[0071] S7: Performance detection.

[0072] In the present embodiment, the material of S1 includes 80 parts of titanium powder, 12 binder, 4 parts of boron carbide powder, 4 parts of aluminum powder, 2 magnesium powder, 2.5 copper powder, 3 parts of nickel powder, carbon fiber powder 8 0.8 parts of the modifier.

[0073] Preferably, the carbon fiber powder preparation is:

[0074] First, take out the carbon fiber raw material to degenerate, clean, dry treatment;

[0075] Second, and use a crusher to smash and use a 500 mesh filter multiple screening;

[0076] Third, weigh the amount of carbon fiber powder.

[0077] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com