Pickering emulsion with CO2/double-response type surfactant and preparation method of Pickering emulsion

A surfactant and emulsion technology, applied in the field of Pickering emulsion and preparation, can solve the problems of unsuitability for industrial application, complex chemical synthesis process, cumbersome preparation, etc., and achieve simple preparation method, simple response process, and low dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step, preparation of carboxyl-modified nano-silica particles

[0033] First, accurately weigh 5g of silica nanoparticles with a balance, measure 9mL of aminopropyltriethoxysilane and 100mL of dehydrated toluene with a graduated cylinder, add them to a 250mL flask, and then add a few drops of triethylamine to make Accelerator, put the flask into an oil bath at 110°C for magnetic stirring, and reflux for 5 hours. After the reaction, cool down to room temperature, centrifuge through a centrifuge, remove the solvent toluene, wash and centrifuge with water and absolute ethanol several times, and finally dry to obtain surface aminated silica nanoparticles.

[0034]Weigh 3g of surface-aminated silica nanoparticles, add them to a flask containing 100mL of N,N-dimethylformamide solvent, put them into an ultrasonic instrument and sonicate for about 10min, so that the nanoparticles are fully dispersed in the solvent, Then add 6g of succinic anhydride, then drop a few dr...

Embodiment 2

[0039] CO 2 / oxidation-reduction is the performance detection of the dual stimulus-responsive surfactant stable emulsion of switch, the ferrocene surfactant of different quality is added into 10mL deionized water, makes it disperse evenly in deionized water with ultrasonic instrument (surface Concentration of active agent aqueous solution<CMC), add above-mentioned solution and 10mL paraffin oil in a 30mL glass vial, utilize vortex shaker to emulsify 3min under 1000rpm rotating speed, can not obtain stable emulsion, show that when surfactant concentration When it is less than CMC, no stable emulsion can be formed.

Embodiment 3

[0041] CO 2 Surface activation of carboxylated silica nanoparticles by dual stimuli-responsive surfactants / redox switches.

[0042] Option One:

[0043] Add 0.00299g of ferrocene surfactant into 10mL of deionized water (the use concentration based on the water phase is 1.0×10 -3 mol L -1 ), at the same time, add 0.1g of carboxyl-modified nano-silica particles of different sizes (the water phase is a reference concentration of 1wt%, and the primary particle diameter is respectively 20nm, 30nm, 50nm, 100nm, 200nm), using an ultrasonic instrument It was evenly dispersed in deionized water, and the above solution was added into a 30mL glass vial containing 10mL of paraffin oil, and emulsified with a vortex shaker at 1000rpm for 3min to obtain a stable Pickering emulsion. The results are shown in Table 1.

[0044] Option II:

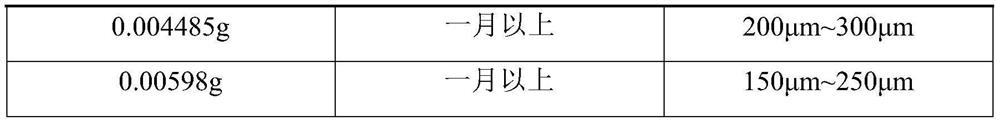

[0045] Ferrocene surfactants of different concentrations were added to 10mL deionized water (masses were respectively 0.000299g, 0.001495g, 0.00299g, 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com