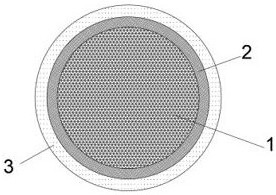

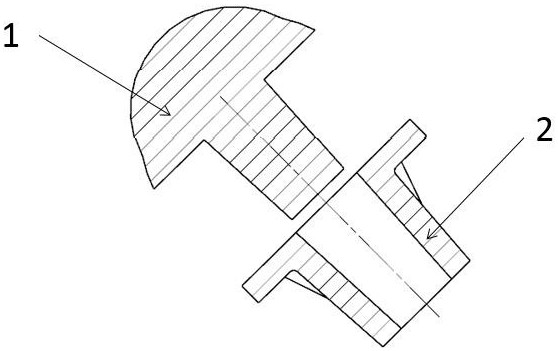

Ultrasonic-assisted 3D printing medical porous renewable handle-free shoulder joint humerus head with cage

A 3D printing and humeral head technology, applied in the field of medical implants, can solve the problems of unfavorable replacement surgery, low connection stability, poor biocompatibility, etc., achieve good adhesion and stretching of osteoblasts, and reduce operation time and blood loss, the effect of easy implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Step 1: Create a 3D model

[0041] Firstly, through CT scanning equipment, scan the bone tissue structure of the part of the human body that needs bone replacement, use 3D reconstruction software to obtain the size and shape of the humeral head, and then use 3D design software to obtain the size and size of the sessile cage, and establish A three-dimensional structural data model of the bone tissue structure of the part.

[0042] Step 2: Preparation of nano-mixed metal powder

[0043] The molar ratio of metal Ti powder, Mg particles, Si particles, Ca particles, Cu particles, and Ag particles: (25-50): (15-30): (20-40): (5-10): (3 -6): (5-10) After uniform mixing and preparation, the mixture is subjected to high-energy ball milling so that the maximum ball diameter does not exceed 100nm to obtain ultrafine powder. The powder is irradiated to preheat, and the mixed material is continuously stirred within 30 minutes, and the temperature of the raw material is heated to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com