Coated metal plate and drawn-and-ironed can

A technology of deep drawing and thinning, metal plate, applied in metal layered products, devices for coating liquid on the surface, packaging, etc., can solve the problems that the film lamination method cannot be applied to films, film thickness, etc., and achieve excellent can making Processability, excellent productivity, effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

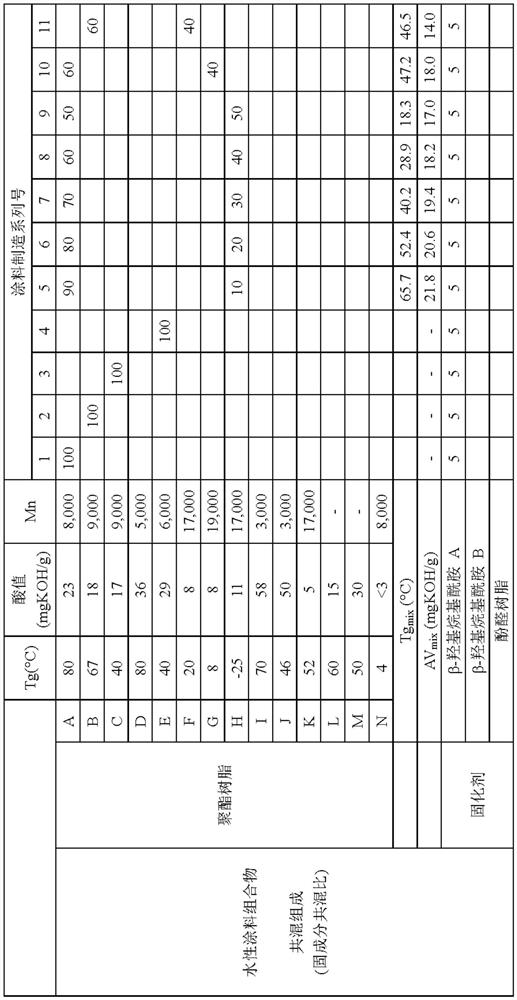

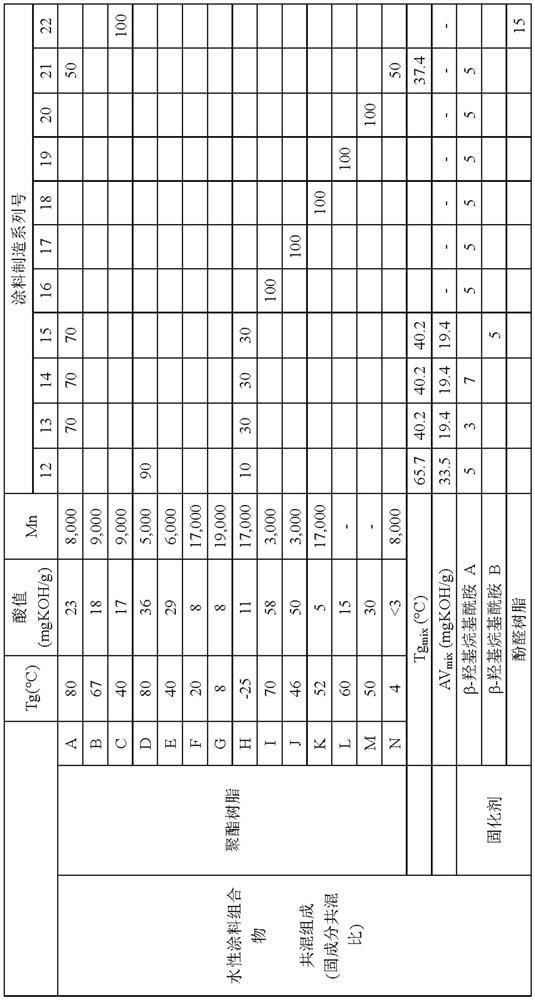

[0139] Hereinafter, the present invention will be described in detail with reference to experimental examples. Here, the term "part" means "part by mass".

[0140] Each measurement item of polyester resin A-K was performed by the following method. Polyester resins A-K are polyester resins that have not been acrylic modified.

[0141] (measurement of number average molecular weight)

[0142] Solids of polyester resins were measured based on gel permeation chromatography (GPC) using a calibration curve of standard polystyrene.

[0143] (measurement of glass transition temperature)

[0144] The solid content of the polyester resin was measured using a differential scanning calorimeter (DSC).

[0145] (measurement of acid value)

[0146] Dissolve 1 g of the solid matter of the polyester resin in 10 ml of chloroform, and titrate with 0.1 N KOH ethanol solution to determine its resin acid value (mgKOH / g). Phenolphthalein was used as an indicator. For polyester resins insolubl...

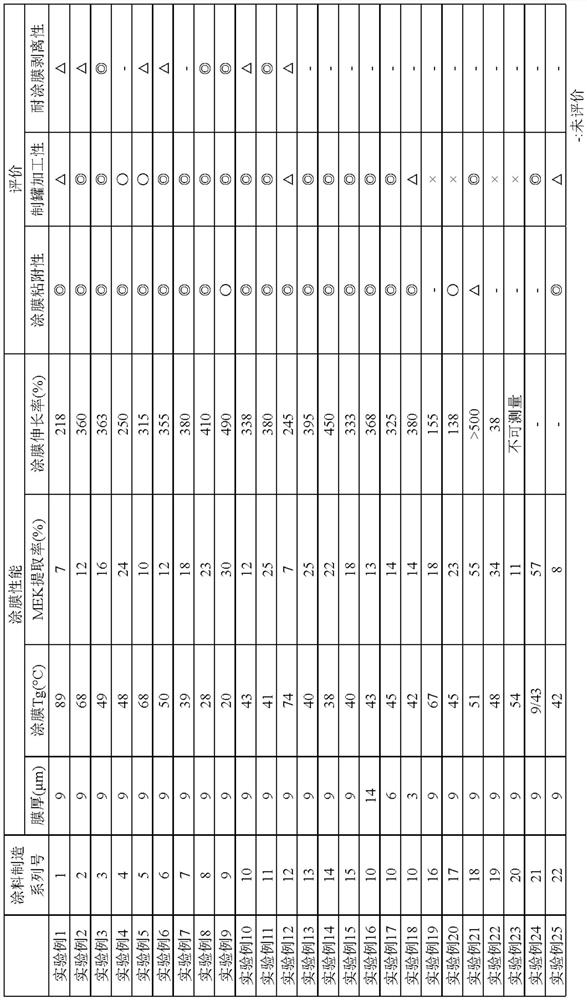

experiment example 1 to 25

[0169] A coated metal sheet used in each experimental example was prepared using the aqueous coating composition obtained in each production example. The coating films on the inner and outer sides of each coated metal sheet were formed using the same aqueous coating composition. For the metal plate, use an aluminum plate (alloy 3104, plate thickness: 0.28mm, chromium weight in the surface treatment film: 20mg / m2) treated with phosphoric acid chromate 2 ). First, the formed outer surface was coated with an aqueous coating composition using a bar coater so that the coating film thickness after drying and firing would be 3 μm, and dried at 120° C. for 60 seconds. Thereafter, the opposite surface to be the inner surface side was coated with an aqueous coating composition using a bar coater in such a manner that the coating film thickness after drying and firing would be as shown in Table 2. The metal plate thus coated was fired at 250° C. (inner temperature of the oven) for 60 s...

experiment example 26 to 40

[0171] Aqueous coating compositions were prepared similarly to Production Example 5, except that the type of polyester resin, type of curing agent, or solid content blending ratio was changed as shown in Table 3.

[0172] The aqueous coating composition thus obtained was used for the production of coated metal panels. The coating films on the inner side and outer side of the coated metal plate were formed using the same aqueous coating composition. The metal plate used here is an aluminum plate (3104 alloy, plate thickness: 0.28mm, chromium weight in the surface treatment film: 20mg / m 2 ). First, the formed outer surface was coated with an aqueous coating composition using a bar coater so that the coating film thickness after drying and firing would be 3 μm, and dried at 120° C. for 60 seconds. After that, the opposite surface on the inner side was coated with an aqueous coating composition using a bar coater in such a manner that the thickness of the coating film after dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com