Polymer-based double-layer nanofiber composite proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and nanofiber membrane, which is applied in the field of proton membrane fuel cells, can solve the problems of poor proton conductivity and structural stability, and achieve the effects of improving proton transmission efficiency, improving proton conductivity, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

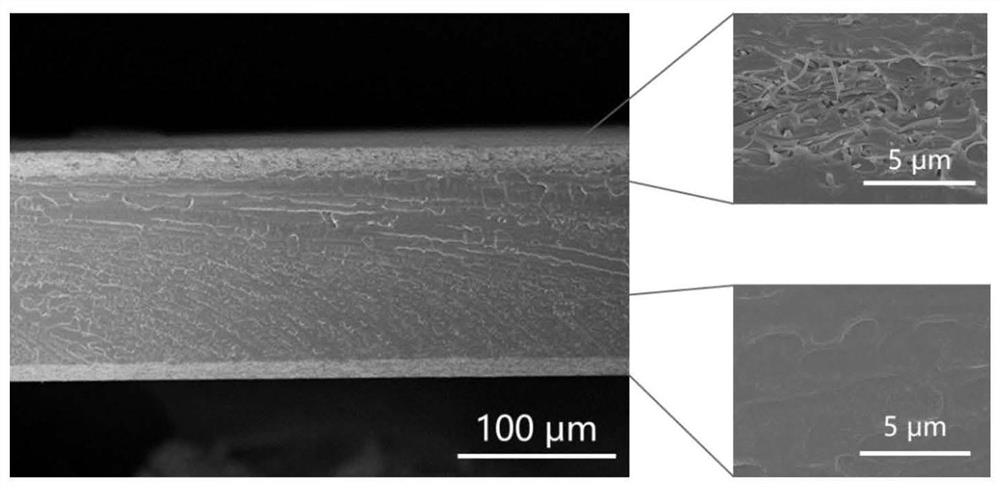

[0031] The preparation method of the above-mentioned polymer-based double-layer nanofiber composite proton exchange membrane provided by the present invention includes: (1) preparing a nanofiber composite membrane, including: using a fiber precursor as a raw material to prepare uncrosslinked nanofiber by electrospinning Fiber membrane; crosslinking the uncrosslinked nanofiber membrane to obtain a crosslinked nanofiber membrane; using a polymer electrolyte as a raw material to form a polymer electrolyte layer on one surface of the crosslinked nanofiber membrane to obtain a nanofiber composite membrane (2) prepare the proton exchange membrane, the proton exchange membrane is made of two nanofiber composite membranes made according to the process of step (1), and its preparation process includes: after the two nanofiber composite membranes are laminated and placed, press The proton exchange membrane is obtained through the combined treatment; wherein, the way of stacking and placi...

Embodiment 1

[0041] (1) Preparation of nanofiber composite membrane

[0042] Preparation of cross-linked nanofiber membrane: add 1.8334g of diaminodiphenyl ether into 30mL of N, N-dimethylformamide, stir evenly, add 2.0121g of pyromellitic anhydride to it and react to obtain polyamic acid solution; then using the polyamic acid solution, a polyamic acid fiber membrane with a fiber diameter of 150nm was obtained by electrospinning; the polyamic acid fiber membrane was placed in a muffle furnace and thermally cross-linked at 300°C. The spinning time was 2 hours, and a polyimide fiber membrane with a fiber diameter of 140nm was obtained; the electrospinning conditions were: voltage 16KV, injection speed 0.05mm / min, receiving distance 15cm, and spinning time 2 hours.

[0043] Preparation of polymer electrolyte solution: 0.637 g of sulfonated polyether ether ketone with a sulfonation degree of 60% was added to 4.267 g of dimethyl sulfoxide solution to prepare a sulfonated polyether ether ketone ...

Embodiment 2

[0047] (1) Preparation of nanofiber composite membrane

[0048] Preparation of cross-linked nanofiber membrane: add 1.8334g of diaminodiphenyl ether into 30mL of N, N-dimethylformamide, stir evenly, add 2.0121g of pyromellitic anhydride to it and react to obtain polyamic acid solution; then using the polyamic acid solution, a polyamic acid fiber membrane with a fiber diameter of 180nm was obtained by electrospinning; the polyamic acid fiber membrane was placed in a muffle furnace and thermally cross-linked at 300°C. The bonding time was 4 hours, and a polyimide fiber membrane with a diameter of 180 nm was prepared; wherein, the electrospinning conditions were: voltage 16KV, injection speed 0.07mm / min, receiving distance 15cm, and spinning time 5 hours.

[0049]Preparation of polymer electrolyte solution: 1.3365g of sulfonated polyether ether ketone with a sulfonation degree of 60% was added to 8.944g of dimethyl sulfoxide solution and 0.2673g of phosphotungstic acid to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com