Preparation and application of in-situ polymerization coated modified silicon-based negative electrode material

A silicon-based negative electrode material and a technology of silicon-based materials, applied in the field of electrochemical energy storage, can solve the problems of low first Coulombic efficiency, uneven distribution of inorganic substances and organic polymers, and increase the volume expansion of negative electrode materials, so as to increase the first Coulombic efficiency. Efficiency and cycle stability performance, optimized material interface effect, simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

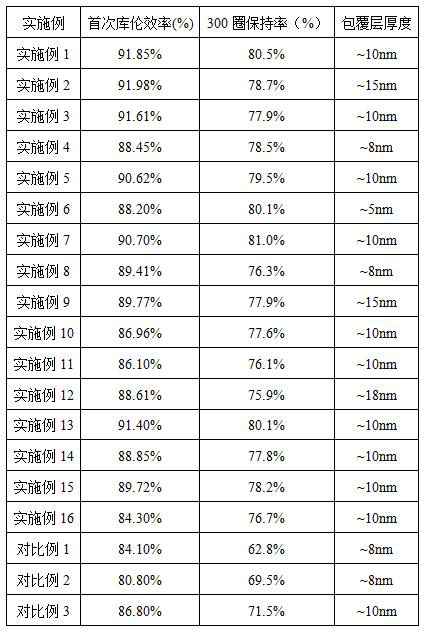

Embodiment 1

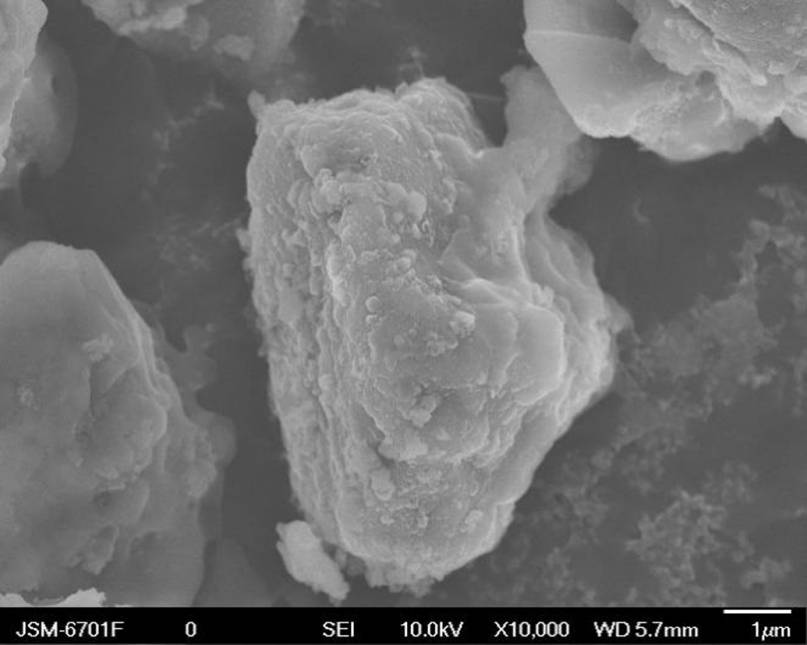

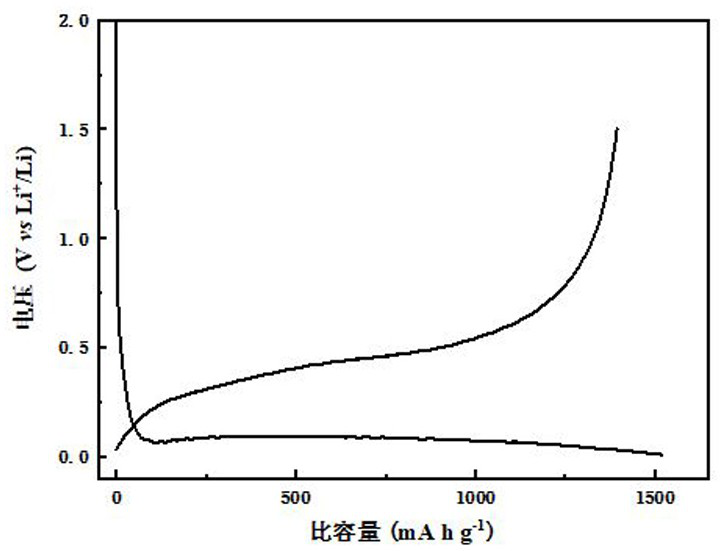

[0049] Embodiment 1 A preparation method of an in-situ polymerization coating modified silicon-based negative electrode material: comprising the following steps:

[0050] S1. Take 10 g of lithium-silicon alloy material (pre-lithiated SiO material) with a median particle size of 5 μm and a specific capacity of 1400 mAh / g and 0.5 g of lithium bis-trifluoromethanesulfonimide (LiTFSI) into 150 ml containing 10v% choline chloride-ethylene glycol solvent (the molar ratio of choline chloride and ethylene glycol is 1:2) in 1,2-dimethoxyethane (DME) mixed solvent, after sonication for 0.5h Stir for 1 h (rotation speed is 500 r / min) to obtain solution A. The whole process of this step is performed in a glove box;

[0051] S2. Add 3g of 1,3-dioxolane (DOL) to the above solution A, and continuously stir for 12 hours (the rotation speed is 150 r / min) to obtain solution B, and obtain a composite coating in which the inorganic matter is uniformly dispersed in the polymer Layer-coated silico...

Embodiment 2

[0054] A preparation method of an in-situ polymerization coating modified silicon-based negative electrode material, comprising the following steps:

[0055] S1. Take 10g of lithium-silicon alloy material (pre-lithiated SiO material) with a median particle size of 5μm and a specific capacity of 1400 mAh / g and 1g of lithium bis-trifluoromethanesulfonimide, and put them in 150ml containing 10v% chloride Choline-ethylene glycol solvent (the molar ratio of choline chloride and ethylene glycol is 1:2) in 1,2 dimethoxyethane (DME) mixed solvent, ultrasonicated for 0.5h and then stirred for 1h (the rotation speed was 500 r / min) to obtain solution A, and the whole process of this step is performed in a glove box;

[0056] S2. Add 3g of 1,3-dioxolane (DOL) to the above solution A, stir continuously for 6h (rotation speed is 150 r / min), obtain solution B, and obtain a composite coating with inorganic substances evenly dispersed in the polymer Layer-coated silicon-based material, this s...

Embodiment 3

[0059] A preparation method of an in-situ polymerization coating modified silicon-based negative electrode material, comprising the following steps:

[0060] S1. Take 10g of lithium-silicon alloy material (pre-lithiated SiO material) with a median particle size of 10μm and a specific capacity of 1400 mAh / g and 0.5g of lithium bis-trifluoromethanesulfonimide (LiTFSI), and put them in 150ml containing 10v% choline chloride-ethylene glycol solvent (the molar ratio of choline chloride and ethylene glycol is 1:2) in 1,2 dimethoxyethane (DME) solvent, sonicated for 0.5 h and stirred for 1 h (rotation speed is 500 r / min) to obtain solution A, the whole process of this step is performed in a glove box;

[0061] S2. Add 2g of 1,3-dioxolane (DOL) to the above solution A, and stir continuously for 12 hours (rotation speed is 150 r / min) to obtain solution B, and obtain a composite coating in which the inorganic matter is uniformly dispersed in the polymer Layer-coated silicon-based mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com