Graphene enhanced phytic acid-based passivator, preparation method and application

A passivating agent and graphene technology, applied in the coating process of metal materials, etc., can solve the problems of easy cracking and poor anti-corrosion performance, and achieve the effects of small production time, improved anti-corrosion ability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The second aspect of the present invention provides a method for preparing a graphene-enhanced phytic acid-based passivator, comprising the following steps: dissolving phytic acid into deionized water, then adding zinc nitrate, stirring evenly, until the phytic acid-based zinc nitrate is completely dissolved ; Then adjust the solution to be alkaline, add aminated modified graphene, and use ultrasonic vibration to stir, so that the graphene is evenly suspended in the solution.

[0030] Further, using sodium hydroxide, potassium hydroxide or ammonia water to adjust the pH;

[0031] Further, the solution is adjusted to pH 10-12.

[0032] The third aspect of the present invention provides a method for using a graphene-enhanced phytic acid-based passivator: directly soak the steel bar whose surface has been degreased and polished in the passivator, take it out after standing for ten minutes, rinse it with distilled water, and use Dry quickly with a hair dryer.

[0033] The...

Embodiment 1

[0036]In terms of parts by mass, dissolve 0.3 parts of phytic acid into 60 parts of deionized water, then add 0.3 parts of zinc nitrate, and stir evenly until the phytic acid-based zinc nitrate is completely dissolved; then slowly add sodium hydroxide, and stir while adding , observe the change of the solution, when the solution changes from turbid to clear, the measured pH is about 10-12; finally add 0.06 parts of modified graphene, and use ultrasonic vibration to stir, so that the graphene is evenly suspended in the solution, and a Graphene-enhanced phytic acid-based passivators.

[0037] Directly soak 10 samples of steel bars whose surface has been degreased and polished in the passivating agent, let it stand for ten minutes, take it out, rinse it with distilled water, and quickly dry it with a hair dryer.

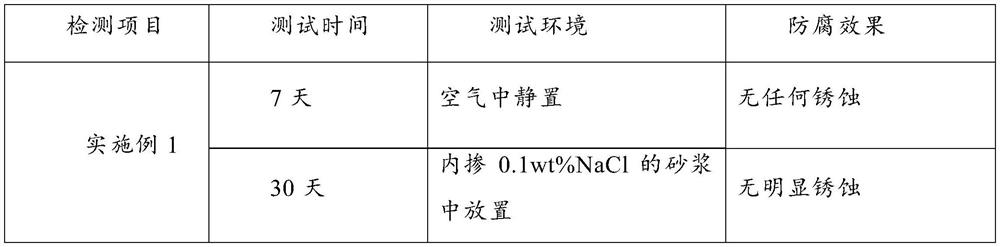

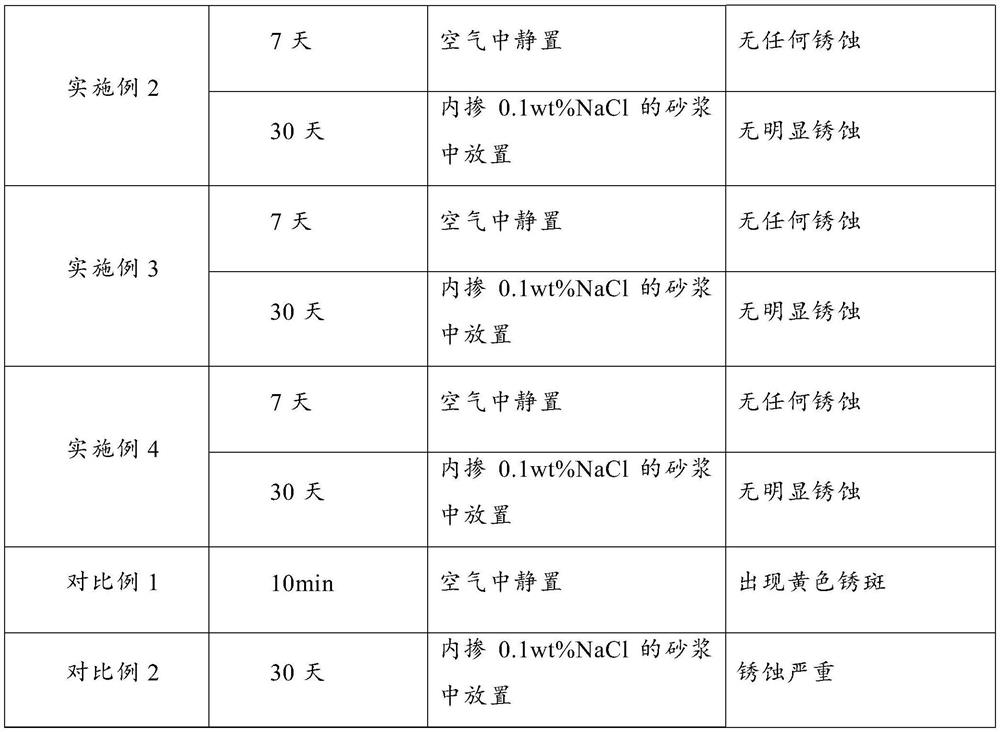

[0038] Put 5 steel bar samples in the air for seven days to observe the changes of the samples; place the other 5 steel bar samples in the mortar mixed with 0.1wt% NaCl...

Embodiment 2

[0040] In terms of parts by mass, dissolve 0.6 parts of phytic acid into 60 parts of deionized water, then add 0.3 parts of zinc nitrate, stir evenly, and wait until the phytic acid-based zinc nitrate is completely dissolved; then slowly add sodium hydroxide, and stir while adding , observe the change of the solution, when the solution changes from turbid to clear, the measured pH is about 10-12; finally add 0.08 parts of modified graphene, and use ultrasonic vibration to stir, so that the graphene is evenly suspended in the solution, and a kind of Graphene-enhanced phytic acid-based passivators.

[0041] Directly soak 10 samples of steel bars whose surface has been degreased and polished in the passivating agent, let it stand for ten minutes, take it out, rinse it with distilled water, and quickly dry it with a hair dryer.

[0042] Put 5 steel bar samples in the air for seven days to observe the changes of the samples; place the other 5 steel bar samples in the mortar mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com