Hydrophobic silica sol precursor composition and preparation method thereof

A composition, silica sol technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of short storage period, insufficient waterproofness, and insufficient dense film formation, so as to solve the problem of short storage period and realize water solubility. The effect of ensuring waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

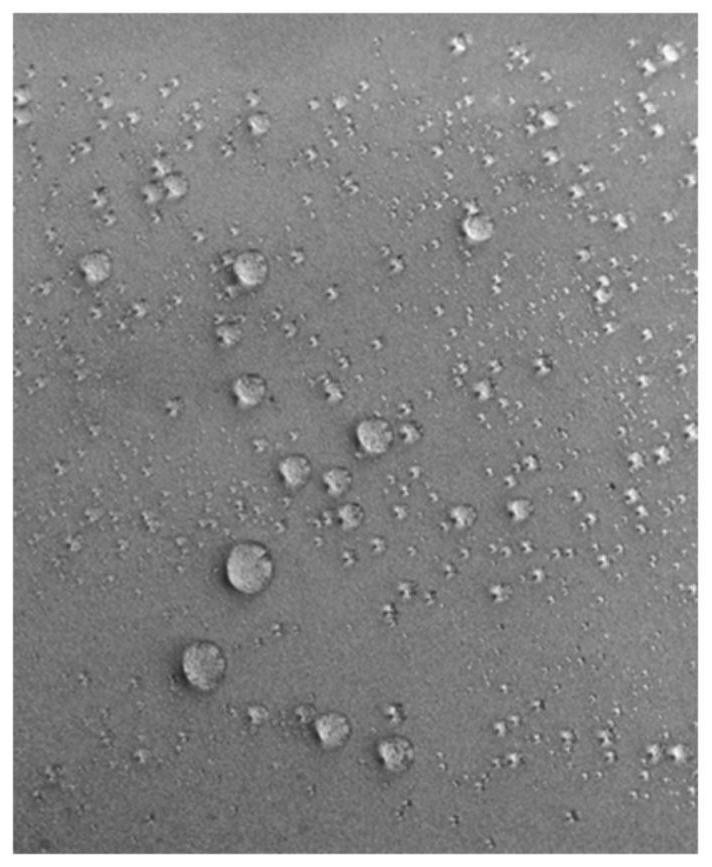

Image

Examples

Embodiment 1

[0071] Preparation of Hydrophobic Silica Sol Precursor Composition 1

[0072] a) 7 parts by weight of hexamethyldisiloxane (monofunctional silane component A), 40 parts by weight of dimethyldimethoxysilane (bifunctional silane component B), 5 parts by weight of KH550 ( Silane coupling agent C), 15 parts by weight of isobutanol (solvent D) and 10 parts by weight of triethanolamine (organic base E) are stirred evenly in a double-layer reactor with a reflux device, heated by hot oil to maintain the system The temperature was refluxed at 65°C to obtain the mixed solution X1,

[0073] b) 15 parts by weight of sodium hydroxide (inorganic base F) is added to 20 parts by weight of water and stirred evenly to obtain lye Y1,

[0074] c) Keep the temperature at reflux at 65°C, and add the lye Y1 into the mixed solution X1 under stirring. After the addition is complete, collect and distill off part of the small molecule solvent, raise the temperature to 90°C and reflux for 0.5h to obtain...

Embodiment 2

[0079] Preparation of Hydrophobic Silica Sol Precursor Composition 2

[0080] a) 5 parts by weight of hexamethyldisiloxane (monofunctional silane component A), 30 parts by weight of hydroxyl silicone oil (bifunctional silane component B), 5 parts by weight of KH790 (silane coupling agent C) 10 parts by weight of n-butanol (solvent D) and 15 parts by weight of diethanolamine (organic base E) are stirred evenly in a double-layer reactor with a reflux device, heated by heating oil, and the temperature of the system is kept at 70 ° C for reflux. Get the mixed solution X2,

[0081] b) 15 parts by weight of potassium hydroxide (inorganic base F) is added to 20 parts by weight of water and stirred evenly to obtain lye Y2,

[0082] c) Keep the temperature at 70°C and reflux, and add the lye Y2 into the mixed solution X2 under stirring. After the addition is complete, collect and distill off part of the small molecule solvent, raise the temperature to 95°C and reflux for 0.5h to obtai...

Embodiment 3

[0087] Preparation of Hydrophobic Silica Sol Precursor Composition 3

[0088] a) 10 parts by weight of hexamethyldisilazane (monofunctional silane component A), 35 parts by weight of dimethyldiethoxysilane (bifunctional silane component B), 5 parts by weight of KH560 ( Silane coupling agent C), 10 parts by weight of ethylene glycol butyl ether (solvent D) and 15 parts by weight of ethanolamine (organic base E) are stirred evenly in a double-layer reactor with a reflux device, and heated by hot oil to keep The temperature of the system was refluxed at 70°C to obtain a mixed solution X3,

[0089] b) 20 parts by weight of potassium hydroxide (inorganic base F) is added to 30 parts by weight of water and stirred evenly to obtain lye Y3,

[0090] c) Keep the temperature at reflux at 70°C, and add the lye Y3 into the mixed solution X3 under stirring. After the addition is complete, collect and fractionate the small molecule solvent, raise the temperature to 95°C and reflux for 0.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com