Method for preparing ethyl silicate hydrolysate capable of being stored for long time

A technology of ethyl silicate and hydrolyzate, applied in coatings, anti-corrosion coatings, etc., can solve problems such as short storage period, inconvenient production and application process, and achieve fast drying speed, short storage period and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a glass four-necked reaction flask equipped with mechanical stirring, reflux condenser, thermometer and water bath heating, 180g of ethyl silicate (40% silicon content) and 90g of absolute ethanol were sequentially added to the four-necked flask, and opened Stir and heat up to 40°C, the stirring speed is 300 rpm, then add 0.3g of 98% concentrated sulfuric acid into 30g of deionized water and stir evenly, then dropwise into a four-necked flask for hydrolysis reaction, the dropping time is controlled at 1 hour, After the dropwise addition, heat up to 70°C and continue the reaction for 2 hours. After the reaction is completed, when the temperature is cooled to below 30°C, filter the ethyl silicate hydrolyzate into the container, and seal it with a cover.

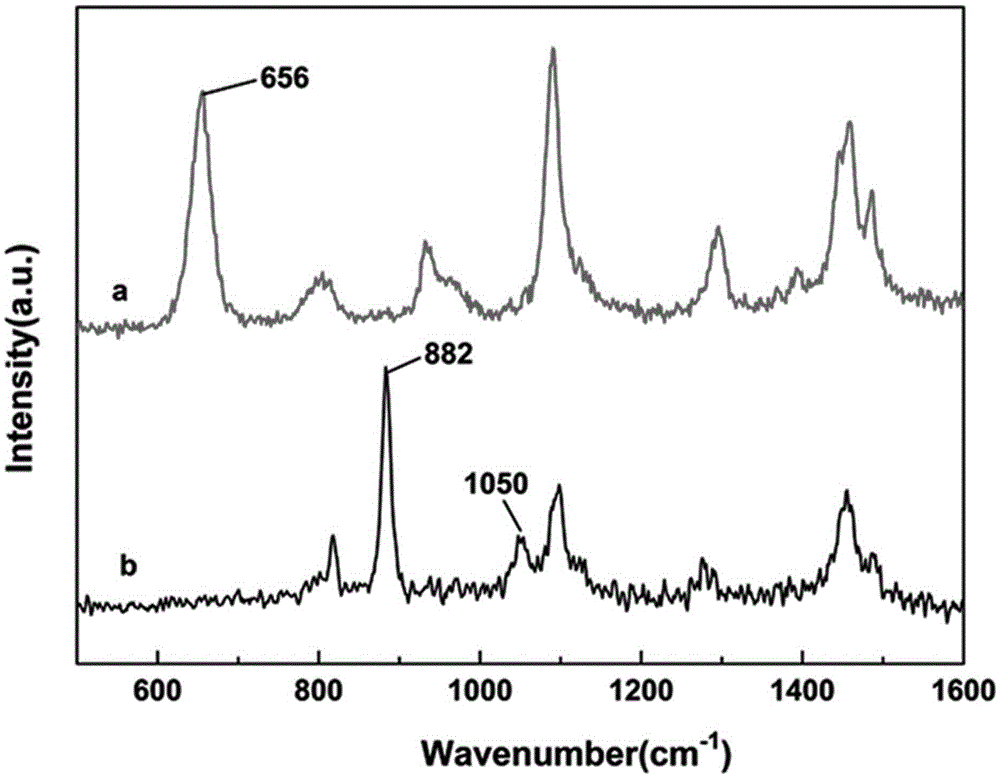

[0021] The Raman spectrum of ethyl silicate hydrolyzate is as follows figure 1 shown by figure 1 It can be known: 656cm after hydrolysis of ethyl silicate -1 The characteristic peak of the Si-O-C bond in ethyl silic...

Embodiment 2

[0027] In a glass four-necked reaction flask with mechanical stirring, reflux condenser, thermometer and water bath heating, 5Kg ethyl silicate (silicon content is 28%) and 4.5Kg absolute ethanol were successively added to the four-necked flask, Turn on the stirring and heat up to 30°C, the stirring speed is 400 rpm, then add 0.03Kg 98% concentrated sulfuric acid into 0.5Kg deionized water and stir evenly, then drop them into a four-necked flask for hydrolysis reaction, and the dropping time is controlled at 1.5 After the dropwise addition, heat up to 60°C and continue the reaction for 3 hours. After the reaction is completed, when the temperature is cooled to below 30°C, filter the ethyl silicate hydrolyzate into the container and seal it with a cover.

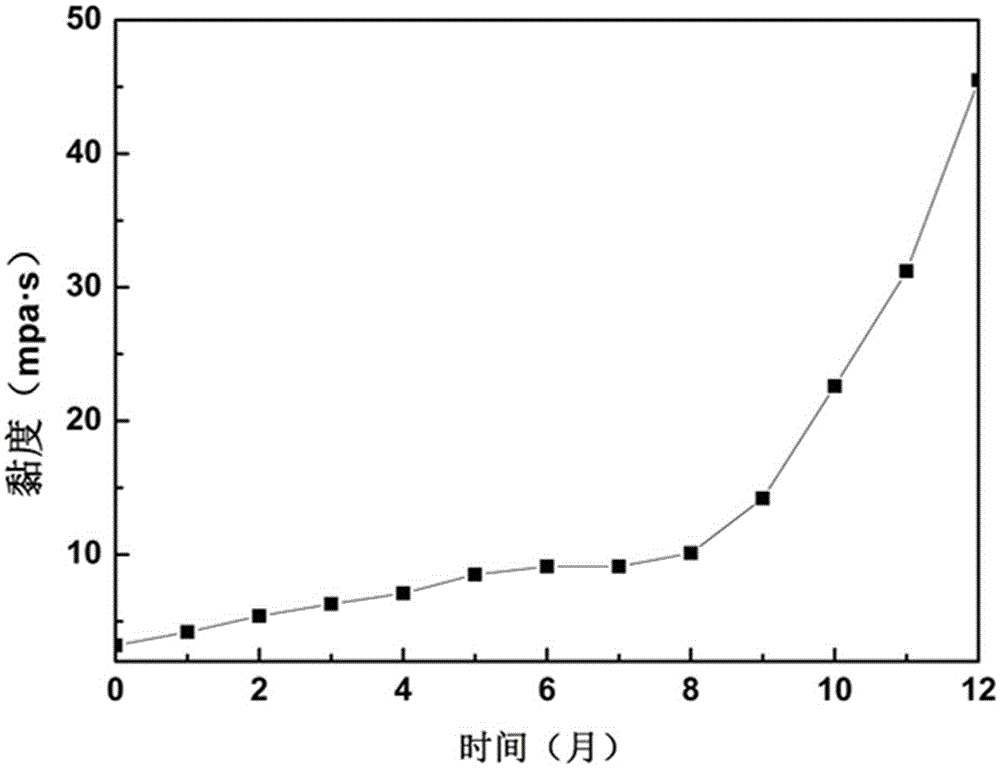

[0028] The ethyl silicate hydrolyzate prepared in Example 2 and the solvent-type inorganic zinc-rich paint main agent A (its composition is mainly polyvinyl butyral, polyamide wax, phosphorus iron powder, zinc powder, precipit...

Embodiment 3

[0032] In a glass four-necked reaction flask equipped with mechanical stirring, reflux condenser, thermometer and water bath heating, 4Kg of ethyl silicate (32% silicon content) and 5Kg of absolute ethanol were sequentially added to the four-necked flask, and opened Stir and heat up to 20°C with a stirring speed of 200 rpm, then add 0.02Kg of 98% concentrated sulfuric acid into 1Kg of deionized water and stir evenly, then dropwise into a four-necked flask for hydrolysis reaction, the dropping time is controlled at 2 hours, After the dropwise addition, heat up to 80°C and continue the reaction for 2 hours. After the reaction is completed, when the temperature is cooled to below 30°C, filter the ethyl silicate hydrolyzate into the container, and seal it with a cover.

[0033] The ethyl silicate hydrolyzate prepared in Example 2 and the solvent-type inorganic zinc-rich paint main agent A (its composition is mainly polyvinyl butyral, polyamide wax, phosphorus iron powder, zinc powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com