Efficient PP flame-retardant master batch and preparation method thereof

A flame retardant masterbatch, high-efficiency technology, applied in the field of flame retardant masterbatch, can solve the problems of poor compatibility between inorganic flame retardants and substrates, failure of flame retardant performance, high price of decabromodiphenylethane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

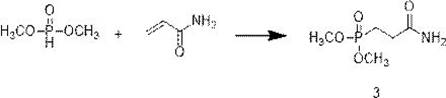

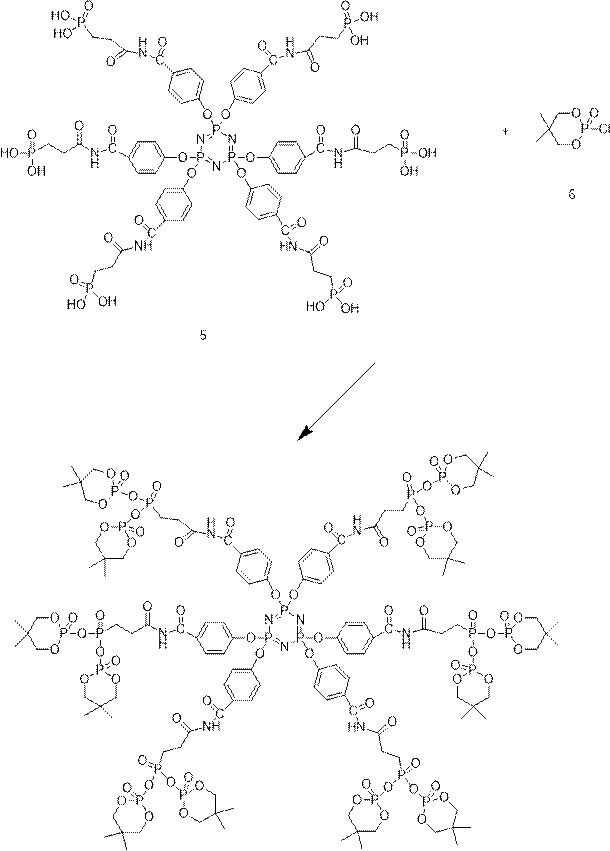

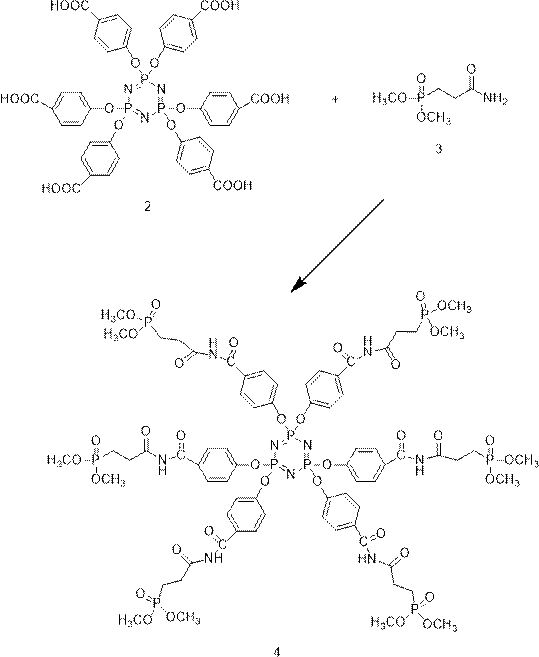

[0038] Auxiliary flame retardants are prepared by the following steps:

[0039] Step S1, add 35.3g of anhydrous potassium carbonate, 19.8g of p-hydroxybenzaldehyde and 198mL of tetrahydrofuran to a dry three-necked flask, feed nitrogen, stir at room temperature to dissolve, add 97mL of tetrahydrofuran of hexachlorocyclotriphosphazene Solution, control the dripping within 1h, reflux reaction for 0.5h, heat up to 65°C, continue reflux reaction for 37h, filter with suction, concentrate the filtrate to one-third of the original volume, add deionized water, stir to precipitate precipitate, filter, filter The cake was washed twice with deionized water, recrystallized twice with ethyl acetate, and dried in an oven at 50°C for 8 hours to obtain intermediate 1, in which hexachlorocyclotriphosphazene in tetrahydrofuran solution The dosage ratio of nitrile and tetrahydrofuran is 8.2g: 100mL;

[0040] Step S2, add 9.8g of intermediate 1 and 12.5mL of concentrated nitric acid with a mass ...

Embodiment 2

[0046] Auxiliary flame retardants are prepared by the following steps:

[0047] Step S1, add 35.5g of anhydrous potassium carbonate, 19.9g of p-hydroxybenzaldehyde and 200mL of tetrahydrofuran to a dry three-necked flask, feed nitrogen, stir at room temperature to dissolve, add 98mL of tetrahydrofuran of hexachlorocyclotriphosphazene Solution, control the drop within 1h, reflux reaction for 0.5h, then heat up to 65°C, continue reflux reaction for 38h, filter with suction, concentrate the filtrate to one-third of the original volume, add deionized water, stir to precipitate precipitate, filter, filter The cake was washed twice with deionized water, recrystallized twice with ethyl acetate, and dried in an oven at 50°C for 9 hours to obtain intermediate 1, in which hexachlorocyclotriphosphazene in tetrahydrofuran solution The dosage ratio of nitrile and tetrahydrofuran is 8.3g: 100mL;

[0048] Step S2, add 10.1g of intermediate 1 and 12.7mL of concentrated nitric acid with a mas...

Embodiment 3

[0054] Auxiliary flame retardants are prepared by the following steps:

[0055] Step S1, add 35.8g of anhydrous potassium carbonate, 20.1g of p-hydroxybenzaldehyde and 203mL of tetrahydrofuran to a dry three-necked flask, feed nitrogen, stir at room temperature to dissolve, and add 100mL of hexachlorocyclotriphosphazene in tetrahydrofuran Solution, control the dripping within 1h, reflux reaction for 0.5h, heat up to 65°C, continue reflux reaction for 40h, filter with suction, concentrate the filtrate to one-third of the original volume, add deionized water, stir to precipitate precipitate, filter, filter The cake was washed 3 times with deionized water, recrystallized 3 times with ethyl acetate, and dried in an oven at 50°C for 10 hours to obtain intermediate 1, in which hexachlorocyclotriphosphazene in THF solution The dosage ratio of nitrile and tetrahydrofuran is 8.5g: 100mL;

[0056] Step S2, add 10.2g of intermediate 1 and 13mL of concentrated nitric acid with a mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com