Device and method for preparing copper-clad aluminum wire through laser welding

A copper-clad aluminum and laser welding technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high current density, large heat-affected parts, undercut or insufficient bonding force in argon arc welding, and achieve the degree of automation And the effect of high production efficiency, good weld surface and internal quality, and no interference from electric and magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

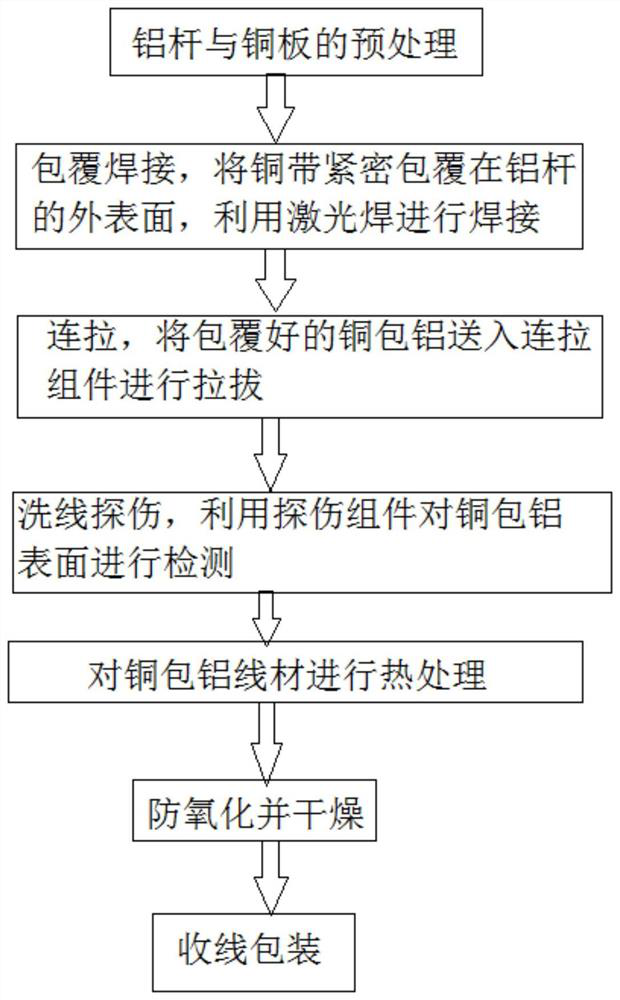

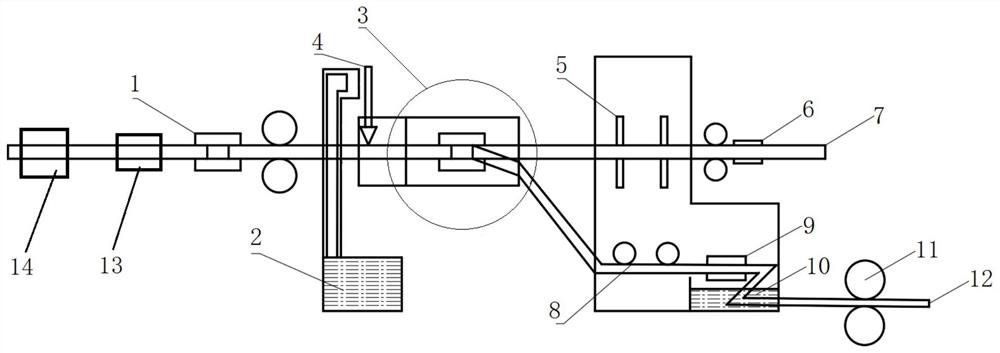

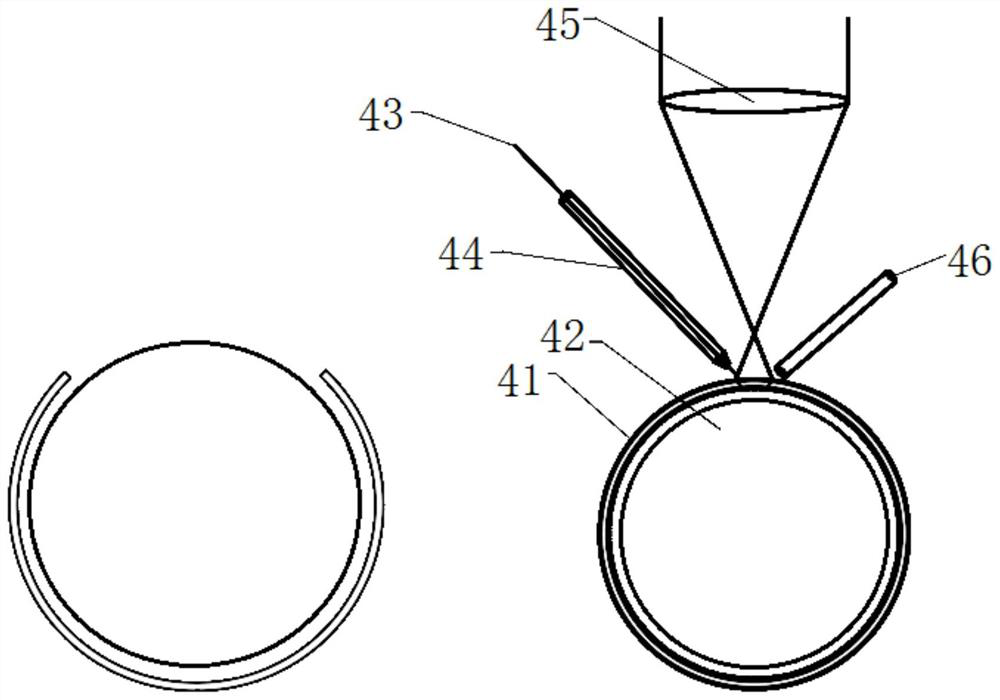

[0036] The present invention utilizes laser welding to prepare the device of copper-clad aluminum wire rod such as figure 2 , image 3 As shown, the device is used to wrap high-quality copper tape concentrically on the outer surface of the aluminum rod, so that a strong interatomic metallurgical bond is formed between the copper layer and the aluminum core, so that it has both the conductivity of copper and the conductivity of aluminum. Composite features of low density, expanding the scope of use, it includes the first straightening component 1, water cooling component 2, cladding component 3, welding component 4, grinding component 5, second straightening component 6, aluminum rod 7, surface grinding brush Component 8, drying component 9, cleaning component 10, roll 11, copper plate 12, continuous pulling component 13 and flaw detection component 14.

[0037] Wherein, roll 11 is arranged on both sides of copper plate 12 rotatably (roll 11 realizes rotation under the drive ...

Embodiment 2

[0053] This embodiment provides a device and method for preparing copper-clad aluminum wires by laser welding, which is roughly the same as the solution in Embodiment 1, except that in step S2, the welding power of laser welding is 250W, and the laser scanning speed is 480mm / min.

Embodiment 3

[0055] This embodiment provides a device and method for preparing copper-clad aluminum wires by laser welding, which is roughly the same as the solution in Embodiment 1, except that in step S2, the welding power of laser welding is 260W, and the laser scanning speed is 490mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com