Nano-zinc oxide protection introduced packaging material and preparation method thereof

A technology of nano-zinc oxide and packaging materials, which is applied in the direction of radiation-absorbing coatings and coatings, which can solve problems affecting light transmittance and performance, and improve the ability to resist ultraviolet radiation, water vapor barrier, and environmental aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

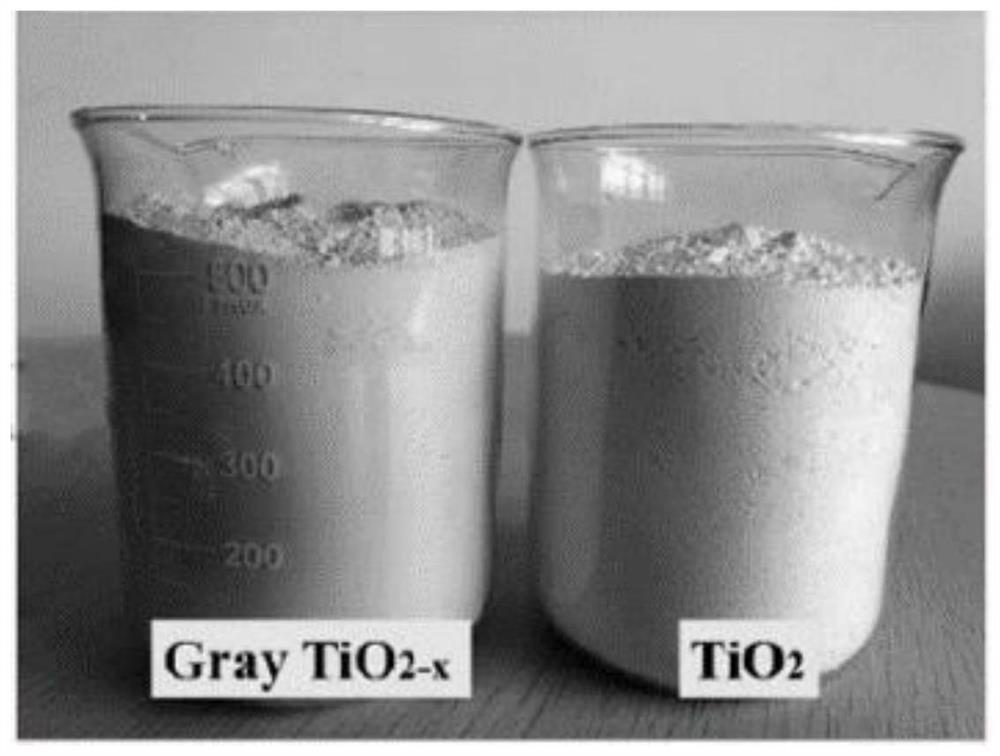

[0042] Embodiment 1: Preparation of encapsulation material of titanium dioxide single coating

[0043] Mix 5g of polybutylmethacrylate, 4g of titanium dioxide, 0.2g of barium sulfate and 50mg of graphene evenly, and add them into a reaction kettle containing a stirrer and a reflux condenser. Add zirconium beads with a volume ratio of 0.5, and grind at a speed of 4000 r / min. When the fineness of the color paste is less than 10 μm, use a filter to filter to obtain the desired color paste.

[0044] 40g of fluorocarbon resin, 35g of acrylic resin, 4g of isocyanate, 1g of propylene glycol methyl ether acetate (PGMEA), 0.4625g of the color paste prepared above, 5g of polyvinylpyrrolidone, 2g of epoxy resin, 2g of polydimethylsiloxane, Put 0.8g of stannous octoate and 10g of absolute ethanol into a reaction kettle containing a stirrer, and disperse for 10 minutes at a stirring speed of 3000r / min to obtain solar battery backsheet coating 1, which is coated with a scraper or casting te...

Embodiment 2

[0046]Embodiment 2: Preparation of encapsulation material introducing nano-zinc oxide protection double-layer coating

[0047] Mix 5g of polybutylmethacrylate, 4g of nano-zinc oxide, 0.2g of barium sulfate and 50mg of graphene evenly, and add them into a reaction kettle containing a stirrer and a reflux condenser. Add zirconium beads with a volume ratio of 0.5, and grind at a speed of 4000 r / min. When the fineness of the color paste is less than 5 μm, use a filter to filter to obtain the required color paste.

[0048] 40g of fluorocarbon resin, 35g of acrylic resin, 4g of isocyanate, 1g of propylene glycol methyl ether acetate (PGMEA), 0.4625g of the color paste prepared above, 5g of polyvinylpyrrolidone, 2g of epoxy resin, 2g of polydimethylsiloxane, Put 0.8g of stannous octoate and 10g of absolute ethanol into a reaction kettle containing a stirrer, and disperse for 10 minutes at a stirring speed of 3000r / min to obtain solar battery backsheet coating 2, which is coated with ...

Embodiment 3

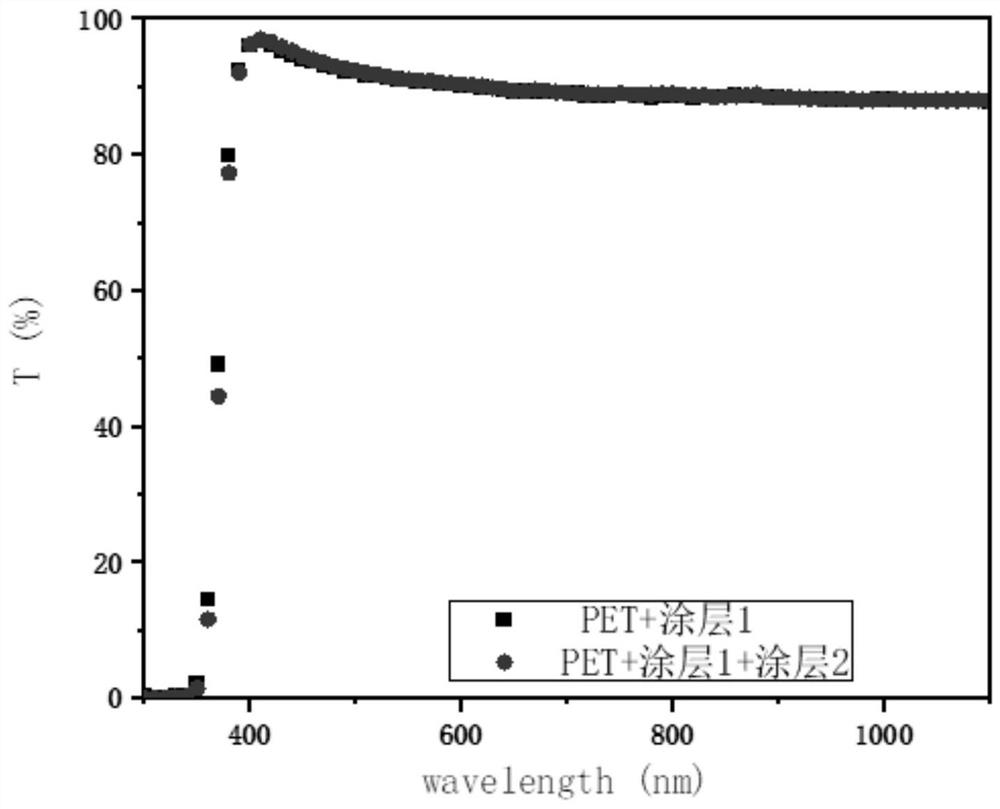

[0050] Example 3: Performance comparison of packaging materials with different coating treatments

[0051] Using an ultraviolet-visible-near-infrared spectrophotometer, the transmittances of the two different packaging materials obtained in the above examples to light of different wavelengths were studied.

[0052] image 3 The transmittance of the packaging material with a single coating of titanium dioxide and the packaging material with a double coating of nano-zinc oxide protection to light with a wavelength of 300-1100nm can be seen from the results in the figure. The transmittance of the material to ultraviolet rays is lower, indicating that the introduction of nano-zinc oxide absorbs more ultraviolet rays to achieve the protective effect on the inner layer of titanium dioxide; Figure 4 In order to introduce the difference histogram of the transmittance of the double-coated packaging material protected by nano-zinc oxide and the single-coated titanium dioxide to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com