A kind of preparation method of polycarbonate surface coating new material

A technology of surface coating and polycarbonate, which is applied in the field of preparation of new materials for polycarbonate surface coating, can solve the limitation of wear resistance in the wide application of polycarbonate materials, the wear resistance of polycarbonate materials, hydrolysis resistance and ultraviolet resistance. Irradiation, poor alkali resistance and other problems, to achieve the effect of enhanced service life and performance, salt spray resistance, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

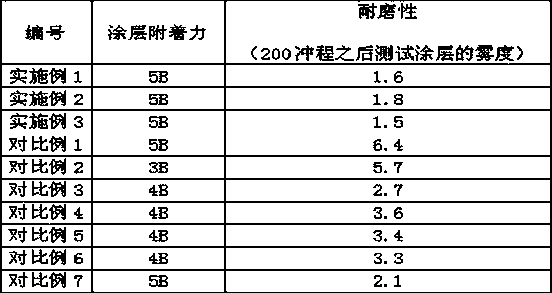

Examples

Embodiment 1

[0019] A preparation method of a new polycarbonate surface coating material, the preparation technical scheme is as follows:

[0020] According to the number of parts by mass: 160 parts of modified silica sol base material and 12 parts of silane coupling agent are inserted into the reactor, heated to 50°C, stirred and reacted for 70 minutes, and then 8 parts of carbonate block polymer are added, After continuing to stir for 25min, add 15 parts of propylene glycol dimethyl ether, 18 parts of ethylene glycol butyl ether, 0.3 part of palm oleeth-60 hexyl dicarbamate, 0.04 part of stearyl hydroxyethyl imidazoline Nitrogenium chloride, 1.3 parts of tetrabutylammonium hydroxide and 0.8 parts of ultraviolet absorber nano-titanium oxide, heat preservation at 55 ° C, and stir for 90 minutes to obtain a new polycarbonate surface coating material.

[0021] The silane coupling agent is vinyltriethoxysilane.

[0022] Described modified silica sol base material is prepared according to the...

Embodiment 2

[0028] A preparation method of a new polycarbonate surface coating material, the preparation technical scheme is as follows:

[0029] According to the number of parts by mass: 150 parts of modified silica sol base material and 9 parts of silane coupling agent are inserted into the reactor, heated to 40°C, stirred and reacted for 60 minutes, and then 5 parts of carbonate block polymer are added, After continuing to stir for 20min, add 12 parts of propylene glycol dimethyl ether, 15 parts of ethylene glycol butyl ether, 0.1 part of palm oleeth-60 hexyl dicarbamate, 0.01 part of stearyl hydroxyethyl imidazoline Nitrogenium chloride, 1.0 part of tetrabutylammonium hydroxide and 0.5 part of ultraviolet absorber nano-titanium oxide are kept at 50°C and stirred for 60 minutes to obtain a new polycarbonate surface coating material.

[0030] The silane coupling agent is methylvinyldimethylsilane.

[0031] Described modified silica sol base material is prepared according to the followi...

Embodiment 3

[0037] A preparation method of a new polycarbonate surface coating material, the preparation technical scheme is as follows:

[0038]According to the number of parts by mass: 180 parts of modified silica sol base material and 16 parts of silane coupling agent were inserted into the reactor, heated to 60°C, stirred and reacted for 80 minutes, and then 10 parts of carbonate block polymer were added, After continuing to stir for 30min, add 18 parts of propylene glycol dimethyl ether, 20 parts of ethylene glycol butyl ether, 0.6 part of palm oleeth-60 hexyl dicarbamate, 0.06 part of stearyl hydroxyethyl imidazoline Nitrogenium chloride, 1.5 parts of tetrabutylammonium hydroxide and 1.0 part of ultraviolet absorber nano-titanium oxide are kept at 60°C and stirred for 120 minutes to obtain a new polycarbonate surface coating material.

[0039] The silane coupling agent is 3-glycidyloxypropyltrimethoxysilane.

[0040] Described modified silica sol base material is prepared according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com