Preparation method of cellulose-based self-reinforcing material

A technology of reinforcing materials and cellulose, which is applied in the field of preparation of cellulose-based self-reinforcing materials, can solve the problems that the anti-ultraviolet aging performance of materials needs to be improved, cellulose cannot realize full shielding in the ultraviolet region, and the anti-ultraviolet aging performance is insufficient, etc., to achieve Excellent UV full shielding performance, excellent anti-ultraviolet aging performance, and the effect of improving anti-ultraviolet aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

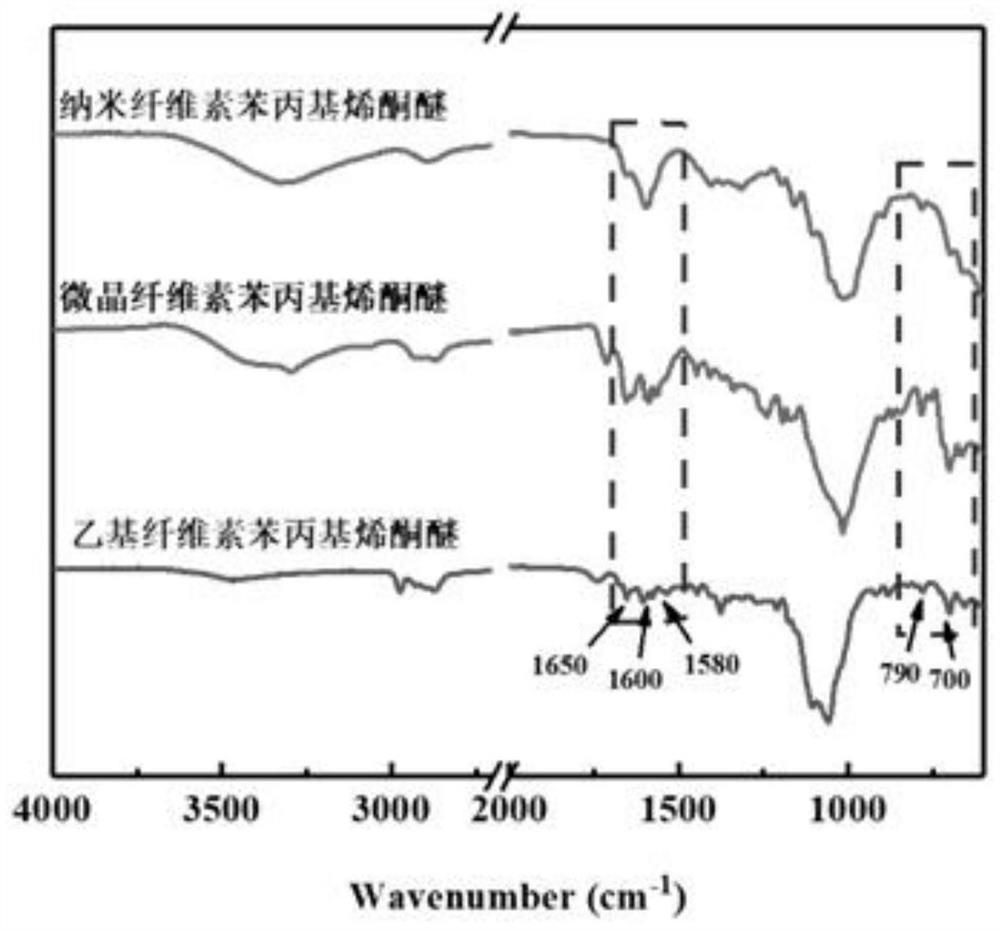

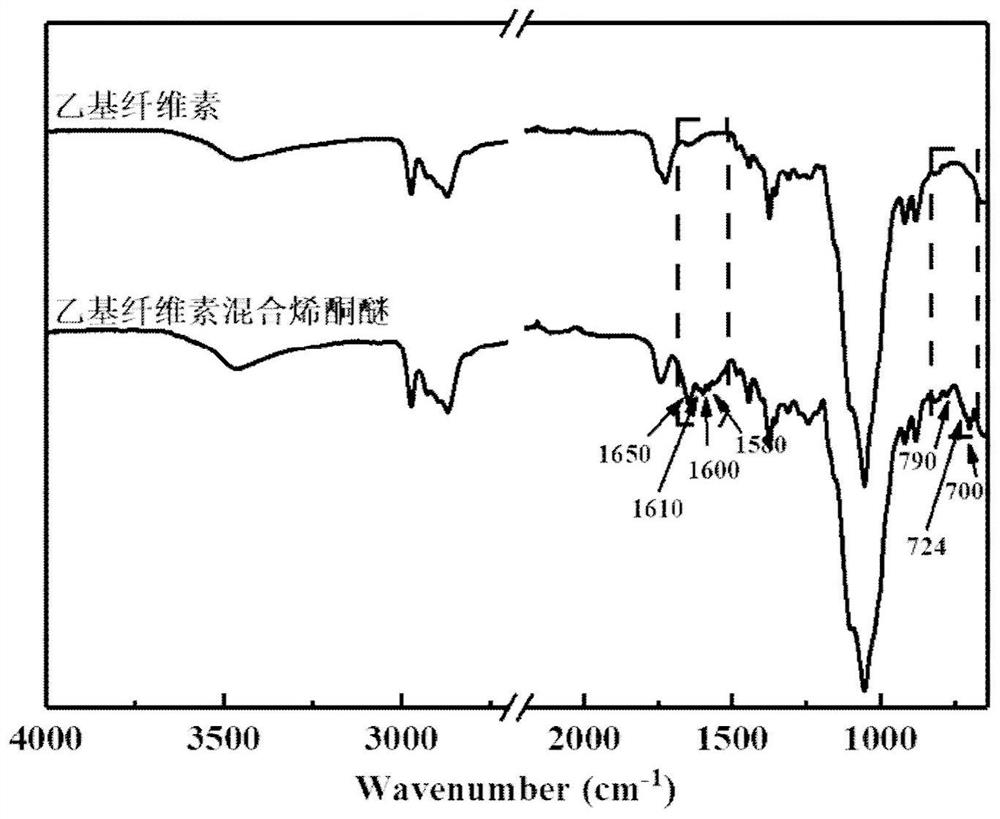

[0034] (1) Preparation of cellulose ether compounds: Take 10 g of 2% cellulose ionic liquid solution and add it to the reaction flask, and add 0.482g of 1-phenyl-2-propyn-1-one and 0.045g of dimethylaminopyridine (DMAP) were stirred at room temperature for 4 hours to obtain cellulose phenylpropyl ketene ether.

[0035] (2) Preparation and self-reinforcement of cellulose phenylpropyl ketene ether gel: Cast cellulose phenylpropyl ketene ether in the above step (1) into a plastic petri dish, store at 4°C for 3 hours, and finally Deionized water and ethanol washing purification obtained from reinforced cellulose phenylpropenyl ketene ether gel.

[0036] The self-reinforcing cellulose gel can also be obtained by irradiating the cellulose gel obtained above under a 365 nm ultraviolet lamp for 2 hours.

Embodiment 2

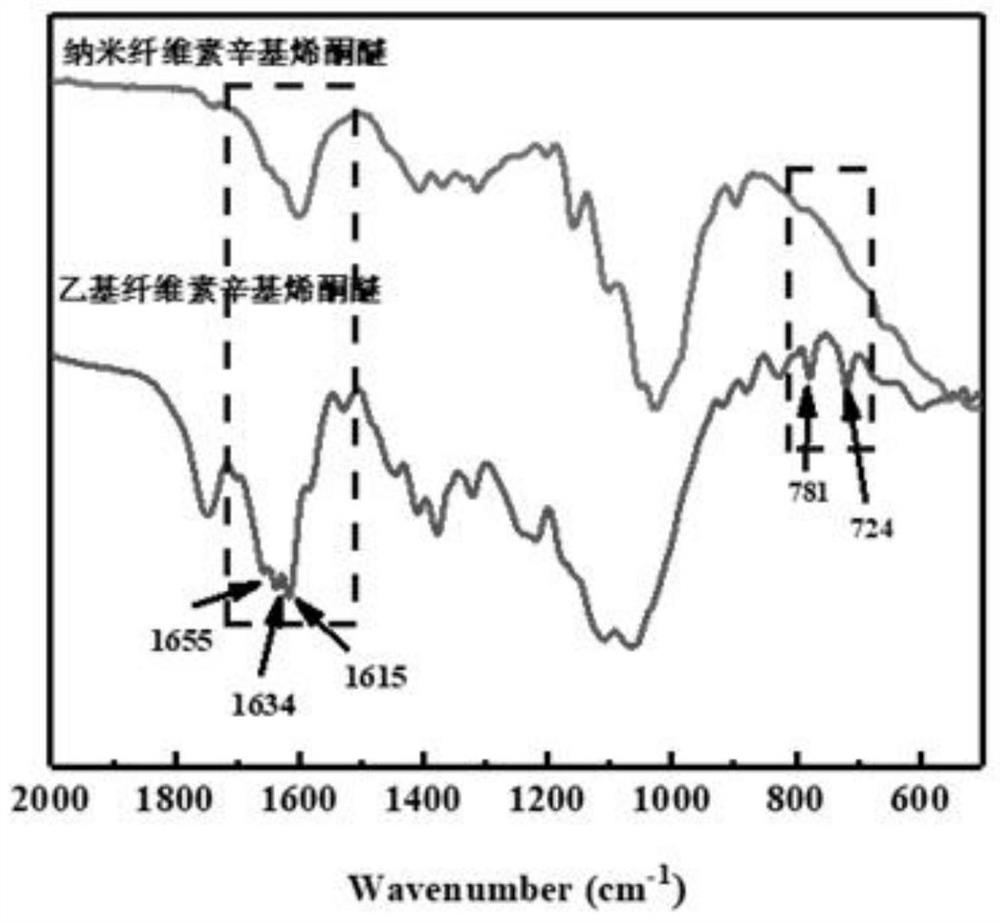

[0038] (1) Nanocellulose can be synthesized according to the synthesis method in the open literature (Yu, J. Cellulose 2019, 26(10), 6023-6034).

[0039] After solvent exchange, 0.162 g of nanocellulose (1 mmol AGU) was ultrasonically dispersed in DMF, and then 0.130 g of 1-phenyl-2-propyn-1-one (PPK, 1 mmol) and 0.012 g of dimethylaminopyridine (DMAP , 0.1 mmol) was added to the nanocellulose dispersion, and reacted for 4 hours at room temperature; finally, the nanocellulose phenylpropyl ketene ether (TOCNPPK) was obtained by ethanol washing and purification.

[0040] (2) Preparation and self-reinforcement of nanocellulose phenyl propyl ketene ether film: TOCNPPK film was prepared by solution casting method. Casting 0.4wt% nano-cellulose dispersion liquid into a tetrafluoroethylene mold, drying at 25-80° C. to constant weight, and obtaining a self-reinforced nano-cellulose phenylpropyl ketene ether film.

[0041] The self-reinforced nanocellulose film can also be obtained by...

Embodiment 3

[0044] (1) Nanocellulose phenyl propyl ketene ether (TOCNPPK) was prepared from Example 2.

[0045](2) Preparation and self-reinforcement of nanocellulose phenyl propyl ketene ether film: TOCNPPK film was prepared by solution casting method. The 0.3wt% nano-cellulose dispersion is cast into a tetrafluoroethylene mold, dried at 25-80° C. to constant weight, and the self-reinforced nano-cellulose phenylpropenyl ketene ether film is obtained.

[0046] The cellulose film obtained above can also be exposed to natural light for 2 hours to obtain a self-reinforced nanocellulose film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com