Wear-resistant impact-resistant waterborne epoxy floor paint and preparation method thereof

An epoxy floor paint, impact-resistant technology, applied in the direction of epoxy resin coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem of affecting the appearance of epoxy floors and the use feeling In order to improve the degree of densification, strengthen the mechanical properties and stability, and optimize the wear resistance and impact resistance of the epoxy floor, it can solve problems such as better reinforcement effect and comprehensive performance of epoxy floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

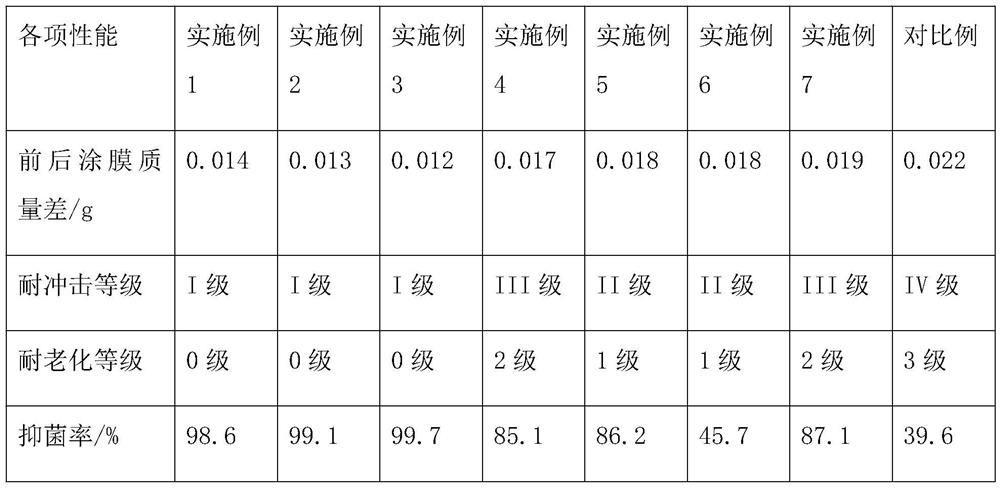

Examples

Embodiment 1

[0039] S1. Preparation of allyltriphenylphosphine bromide / graphene oxide composite:

[0040] 1) Add 15 parts of sodium ion solution to 60 parts of sulfuric acid solution, stir evenly, add 40 parts of graphene oxide, under low pressure, ultrasonically oscillate for 20 minutes, suction filter and dry at 30°C for 10 minutes to obtain a treatment oxidation Graphene;

[0041] 2) Place 30 parts of allyl triphenylphosphine bromide in 70 parts of deionized water and stir evenly, then add 15 parts of graphene oxide for primary treatment, 0.5 parts of hydrochloric acid solution with a mass fraction of 25%, and adjust the rotation speed to 700r / min, and heated at a constant temperature at 35° C., stirred for 1 h, and allowed to stand for 10 min to obtain an allyltriphenylphosphine bromide / graphene oxide composite.

[0042] S2. Preparation of quaternary ammonium salt polymer intermediate:

[0043] 1) Add 20 parts of N,N-dimethyldodecyl tertiary amine to 70 parts of epichlorohydrin, sti...

Embodiment 2

[0053] S1. Preparation of allyltriphenylphosphine bromide / graphene oxide composite:

[0054] 1) Add 20 parts of sodium ion solution to 65 parts of sulfuric acid solution, stir evenly, add 45 parts of graphene oxide, under low pressure conditions, ultrasonically shake for 30 minutes, suction filter and dry at 35°C for 15 minutes to obtain a primary treatment oxidation Graphene;

[0055] 2) After placing 45 parts of allyltriphenylphosphine bromide in 80 parts of deionized water and stirring evenly, add 20 parts of primary treatment graphene oxide, 0.8 parts of hydrochloric acid solution with a mass fraction of 30%, and adjust the speed to 800r / min, and heated at a constant temperature at 40° C., stirred for 1.5 h, and allowed to stand for 15 min to obtain an allyltriphenylphosphine bromide / graphene oxide composite.

[0056] S2. Preparation of quaternary ammonium salt polymer intermediate:

[0057] 1) Add 25 parts of N,N-dimethyldodecyl tertiary amine to 80 parts of epichloroh...

Embodiment 3

[0067] S1. Preparation of allyltriphenylphosphine bromide / graphene oxide composite:

[0068] 1) Add 25 parts of sodium ion solution to 70 parts of sulfuric acid solution, stir evenly, add 50 parts of graphene oxide, under low pressure, ultrasonically oscillate for 40 minutes, suction filter and dry at 40°C for 20 minutes to obtain a treatment oxidation Graphene;

[0069] 2) Put 60 parts of allyltriphenylphosphine bromide in 90 parts of deionized water and stir evenly, then add 25 parts of primary treatment graphene oxide and 1 part of hydrochloric acid solution with a mass fraction of 35%, and adjust the rotation speed to 900r / min, and heated at a constant temperature at 45° C., stirred for 2 h, and allowed to stand for 20 min to obtain an allyltriphenylphosphine bromide / graphene oxide composite.

[0070] S2. Preparation of quaternary ammonium salt polymer intermediate:

[0071] 1) Add 30 parts of N,N-dimethyldodecyl tertiary amine to 100 parts of epichlorohydrin, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com