Diffuse reflection tunnel energy-saving paving ceramic particle and preparation process thereof

A preparation process and ceramic particle technology, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of low reflective effect of white gravel, reduced reflective effect of road surface, and easy damage, etc., to improve light reflection ability , enhance the diffuse reflection effect, and improve the effect of total reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Such as figure 1 The preparation process of energy-saving pavement ceramic particles for a diffuse reflection tunnel includes the following steps:

[0059] mixing green body raw materials to obtain a green body mixture, the green body raw materials including kaolin, quartz, bauxite, albite and potassium feldspar;

[0060] Pressing the green body mixture with a mold to obtain a green body with a texture layer formed on the surface, and calcining the green body;

[0061] The reflective material is prepared, the reflective material is sprayed on the texture layer of the green body, and the ceramic particles covered with the reflective layer on the texture layer are obtained after drying.

[0062] In the above steps, the quartz, bauxite, albite and potassium feldspar in the green body raw materials are respectively dried, crushed, and iron-removed, and then mixed uniformly. Specifically, the quartz, bauxite, albite and potassium feldspar in the green body raw materials ar...

Embodiment 2

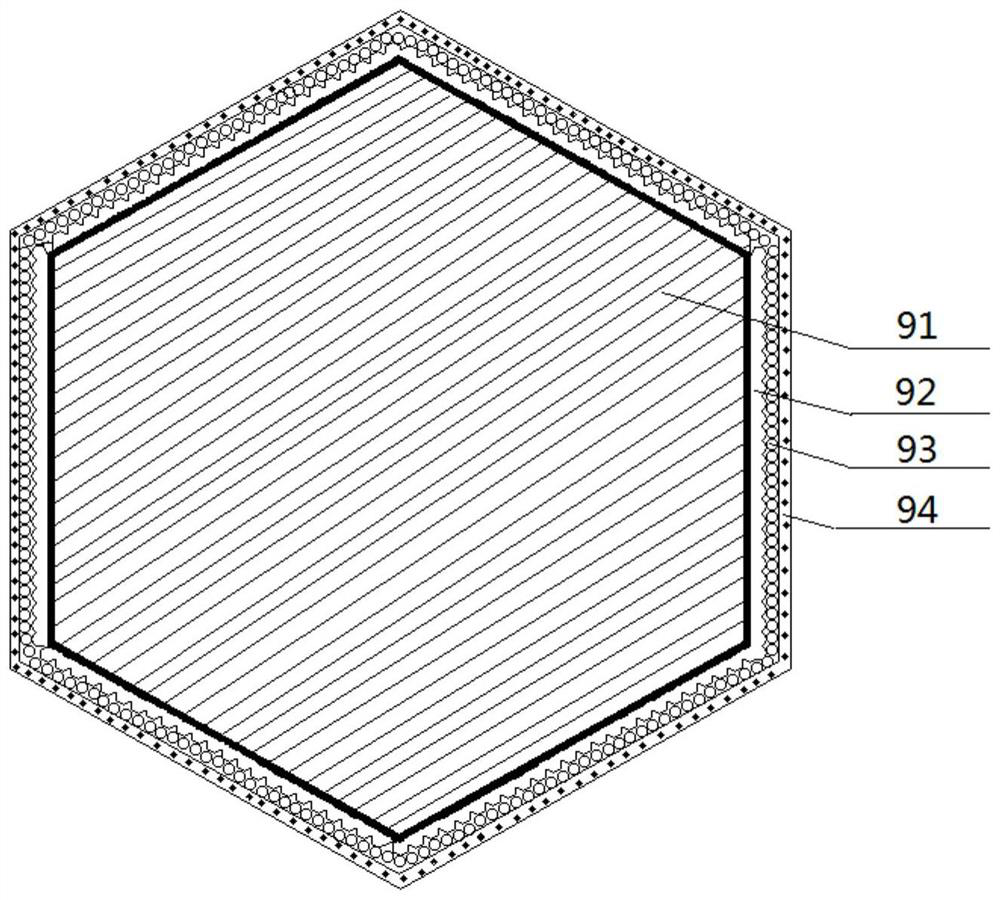

[0066] On the basis of Example 1, after the green body mixture is pressed by pressing molding equipment, a second green body with a textured layer on the surface is obtained, such as Figure 3 to Figure 10 As shown, the press molding equipment includes a conveying device 5 on which several lower molds 4 are installed, and also includes a first upper mold 6 and a second upper mold arranged in sequence along the conveying direction of the conveying device 5 1. The first upper mold 6 and the second upper mold 1 are located above the lower mold 4; the first upper mold 6 is used to press the green body mixture with the lower mold 4 to obtain a first green body, The second upper mold 1 is used to press the first blank with the lower mold 4 to obtain the second blank.

[0067] In some embodiments, the first driving device and the second driving device are hydraulic cylinders or air cylinders. In one or more embodiments, both the first cavity of the first upper mold and the second ca...

Embodiment 3~ Embodiment 7

[0073] The ceramic particles P1-P5 were prepared by the preparation process in the foregoing examples.

[0074] The green body raw materials of ceramic particles P1 include 30 parts by weight of kaolin, 10 parts of quartz, 5 parts of bauxite, 20 parts of albite feldspar, and 10 parts of potassium feldspar. The reflective material is calculated by weight percentage and consists of the following components Composition: 33% barium sulfate powder, 11% titanium dioxide powder, 13% pearl powder, 16% glass microsphere powder, 3% antioxidant, 12% film-forming aid, and the balance is organic solvent.

[0075] The green body raw materials of the ceramic particles P2 include 25 parts by weight of kaolin, 8 parts of quartz, 10 parts of bauxite, 30 parts of albite feldspar, and 15 parts of potassium feldspar. The reflective material is composed of the following components by weight percentage: Ingredients: 35% barium sulfate powder, 11% titanium dioxide powder, 16% pearl powder, 13% glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com