Preparation method of natural biofilm carrier for surfactant wastewater treatment

A biofilm carrier and surfactant technology, which is applied in the field of preparation of natural biofilm carriers, can solve problems such as microplastic pollution, achieve fast film-hanging speed, high environmental friendliness, and improve the effect of film-hanging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Gelatin was extracted from waste leather scraps by alkaline hydrolysis, and 5 g of gelatin was added to 50 ml of phosphate buffer (pH=7.5), stirred in a water bath at 50 °C for 30 min to obtain a homogeneous gelatin aqueous solution. Then 0.2 g of methacrylic anhydride was added to it, and the reaction time was 3 h in a water bath at 50 °C. After the reaction, 100 ml of phosphate buffer was added to dilute to terminate the reaction, and the obtained product was used in a 40 °C constant temperature incubator. Dialyzed with deionized water for 3 days and freeze-dried to prepare methacrylylated modified gelatin containing carbon-carbon double bonds (C=C).

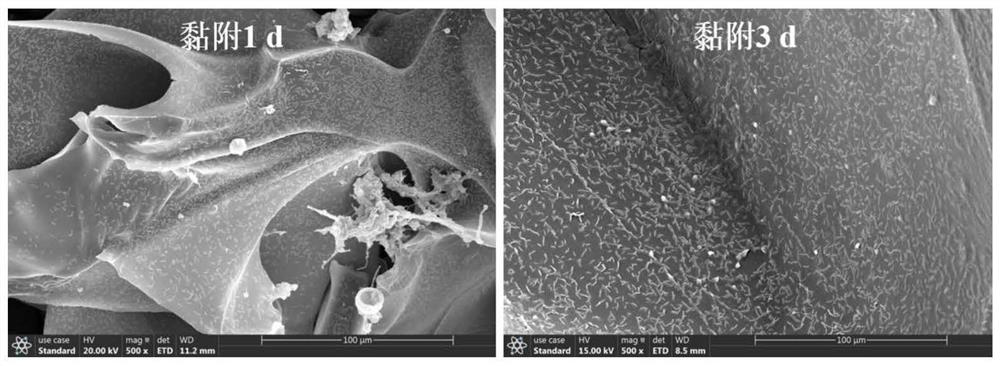

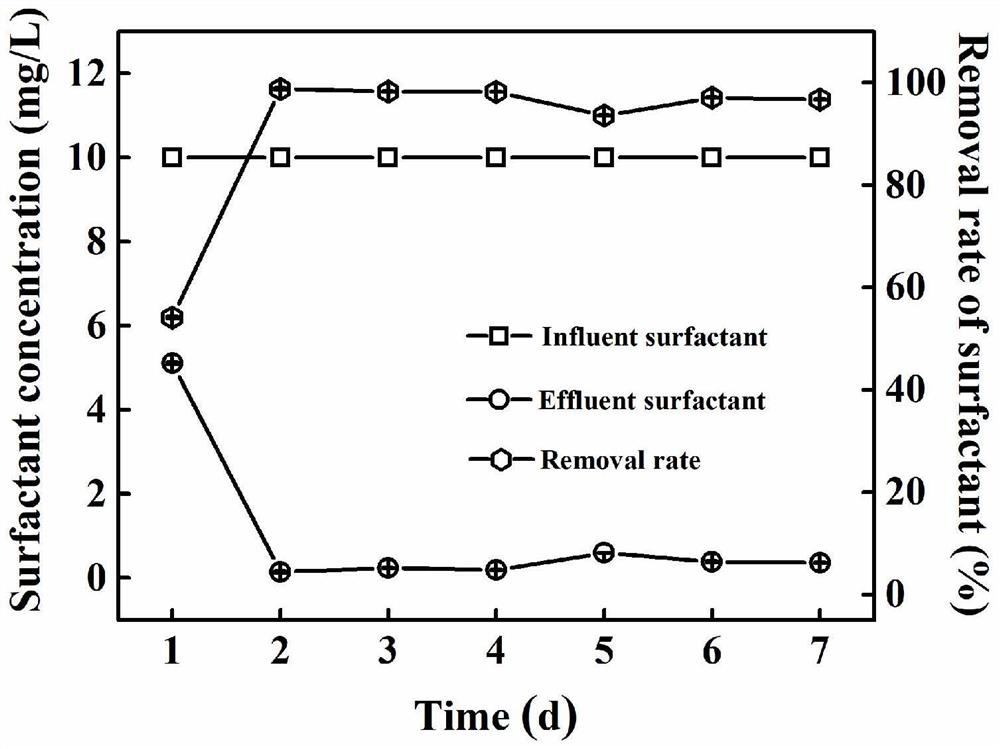

[0028] Prepare 20 ml of methacrylylated modified gelatin aqueous solution with a concentration of 2.5 % w / v, add 0.03 g of photoinitiator to it, and then freeze the mixed solution at -18 ℃ for 16 h; then freeze the frozen system Irradiated under ultraviolet light, the light intensity was 50 mw / cm2, and the irradiation t...

Embodiment 2

[0030] Gelatin was extracted from waste leather scraps by alkaline hydrolysis, and 5 g of gelatin was added to 50 ml of phosphate buffer (pH=7.5), stirred in a water bath at 50 °C for 30 min to obtain a homogeneous gelatin aqueous solution. Then 0.2 g of methacrylic anhydride was added to it, and the reaction time was 3 h in a water bath at 50 °C. After the reaction, 100 ml of phosphate buffer was added to dilute to terminate the reaction, and the obtained product was used in a 40 °C constant temperature incubator. Dialyzed with deionized water for 3 days and freeze-dried to prepare methacryloyl-modified gelatin containing carbon-carbon double bonds (C=C).

[0031] Prepare 20 ml of methacrylylated modified gelatin aqueous solution with a concentration of 2.5 % w / v, add 0.03 g of photoinitiator to it, and then freeze the mixed solution at -18 °C for 16 h; then freeze the frozen system Irradiated under ultraviolet light, the light intensity was 50 mw / cm2, and the irradiation tim...

Embodiment 3

[0033] Gelatin was extracted from waste leather scraps by alkaline hydrolysis, and 5 g of gelatin was added to 50 ml of phosphate buffer (pH=7.5), stirred in a water bath at 50 °C for 30 min to obtain a homogeneous gelatin aqueous solution. Then 0.4 g of methacrylic anhydride was added to it, and the reaction time was 3 h under the condition of 50 °C water bath. After the reaction was completed, 100 ml of phosphate buffer was added to dilute to terminate the reaction. Dialyzed with deionized water for 3 days and freeze-dried to prepare methacryloyl-modified gelatin containing carbon-carbon double bonds (C=C).

[0034]Prepare 20 ml of methacrylylated modified gelatin aqueous solution with a concentration of 2.5 % w / v, add 0.03 g of photoinitiator to it, and then freeze the mixed solution at -18 ℃ for 16 h; then freeze the frozen system Irradiated under ultraviolet light, the light intensity was 50 mw / cm2, and the irradiation time was 5 min to obtain the all-biomass-based gel; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com