Modified formaldehyde decomposition material taking shell powder as carrier and preparation method thereof

A formaldehyde decomposition and shell powder technology, which is applied in the field of modified formaldehyde decomposition materials and their preparation, can solve the problems of inability to realize formaldehyde decomposition, secondary release of formaldehyde, and high purification costs, so as to facilitate blood oxygen transport and improve oxygen content. , The effect of removing indoor odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

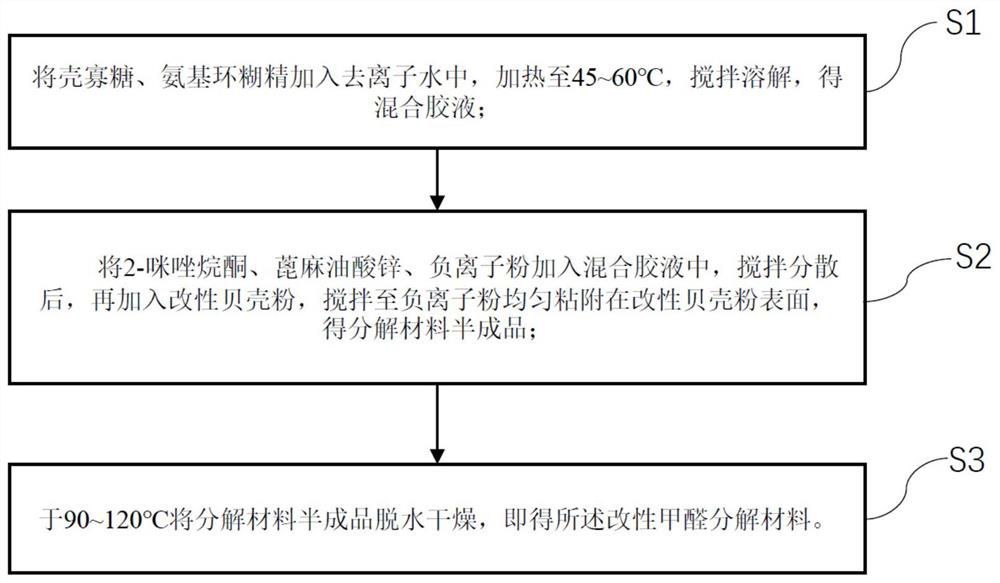

Method used

Image

Examples

Embodiment 1

[0026] A modified formaldehyde decomposition material using shell powder as a carrier, the decomposition material uses modified shell powder as a carrier, uses chitooligosaccharides and aminocyclodextrin as a binder, and loads 2-imidazolidinone and ricinoleic acid Zinc and negative ion powder specifically include the following raw materials in parts by mass:

[0027]

[0028] Described negative ion powder is mixed by the mass ratio of nano-hexacyclic stone powder, nano-tourmaline powder, nano-cerium oxide, nano-lanthanum oxide by 1:1.2:0.02:0.03;

[0029] The preparation method of described modified shell powder is:

[0030] 1: Shells are ground to 50 mesh, added in the dilute hydrochloric acid solution of 0.02mol / L, the solid-to-liquid ratio is controlled to be 0.5g / mL, stirred for 10min, filtered, washed, and dried to obtain shell powder;

[0031] II: the shell powder is placed in a muffle furnace, and calcined at 300° C. for 4 hours under a nitrogen atmosphere to obtain...

Embodiment 2

[0038] A modified formaldehyde decomposition material using shell powder as a carrier, the decomposition material uses modified shell powder as a carrier, uses chitooligosaccharides and aminocyclodextrin as a binder, and loads 2-imidazolidinone and ricinoleic acid Zinc and negative ion powder specifically include the following raw materials in parts by mass:

[0039]

[0040]

[0041] Described negative ion powder is mixed by the mass ratio of 1:2:0.03:0.05 by nano hexacyclic powder, nano tourmaline powder, nano cerium oxide, nano lanthanum oxide;

[0042] The preparation method of described modified shell powder is:

[0043] 1: Shells are ground to 75 orders, added in the dilute nitric acid solution of 0.02mol / L, the solid-to-liquid ratio is controlled to be 0.5g / mL, stirred for 15min, filtered, washed, and dried to obtain shell powder;

[0044] II: the shell powder is placed in a muffle furnace, and calcined at 400° C. for 5 hours under a nitrogen atmosphere to obtain...

Embodiment 3

[0051] A modified formaldehyde decomposition material using shell powder as a carrier, the decomposition material uses modified shell powder as a carrier, uses chitooligosaccharides and aminocyclodextrin as a binder, and loads 2-imidazolidinone and ricinoleic acid Zinc and negative ion powder specifically include the following raw materials in parts by mass:

[0052]

[0053] Described negative ion powder is mixed by the mass ratio of 1:3:0.04:0.07 by nano hexacyclic powder, nano tourmaline powder, nano cerium oxide, nano lanthanum oxide;

[0054] The preparation method of described modified shell powder is:

[0055] 1: Shells are ground to 100 orders, added in the formic acid solution of 0.02mol / L, the control solid-liquid ratio is 0.5g / mL, stirred for 15min, after filtering, washing and drying, shell powder is obtained;

[0056] II: the shell powder is placed in a muffle furnace, and calcined at 500° C. for 6 hours under a nitrogen atmosphere to obtain the pretreated she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com