Method for preparing taurine from mussels

A technology of taurine and mussel, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low extraction rate and high extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

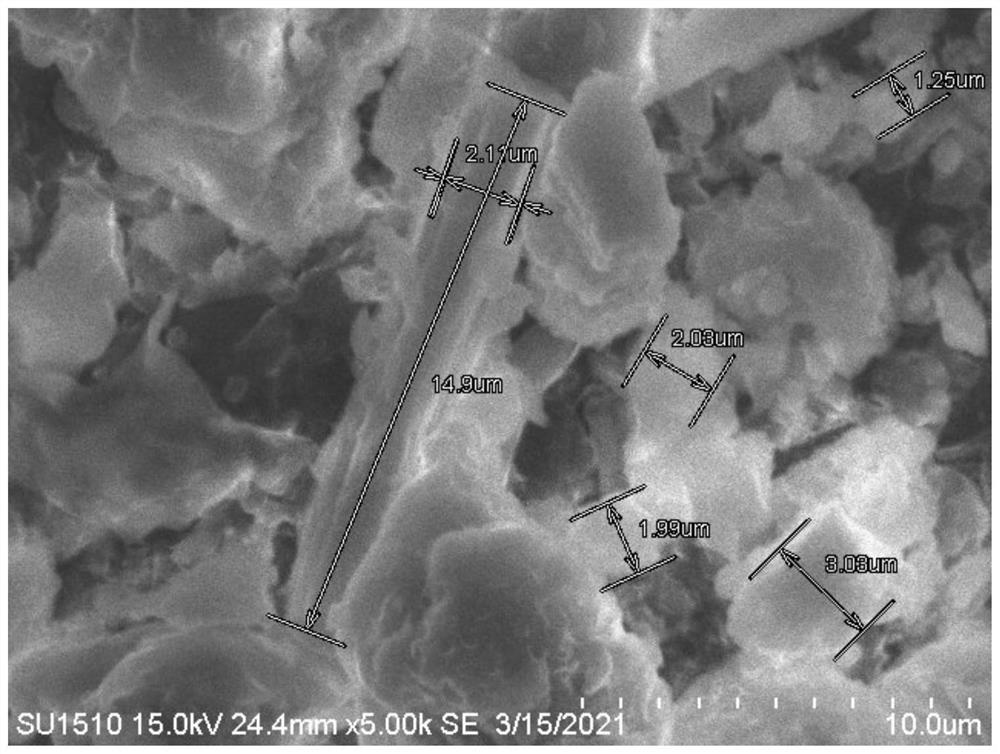

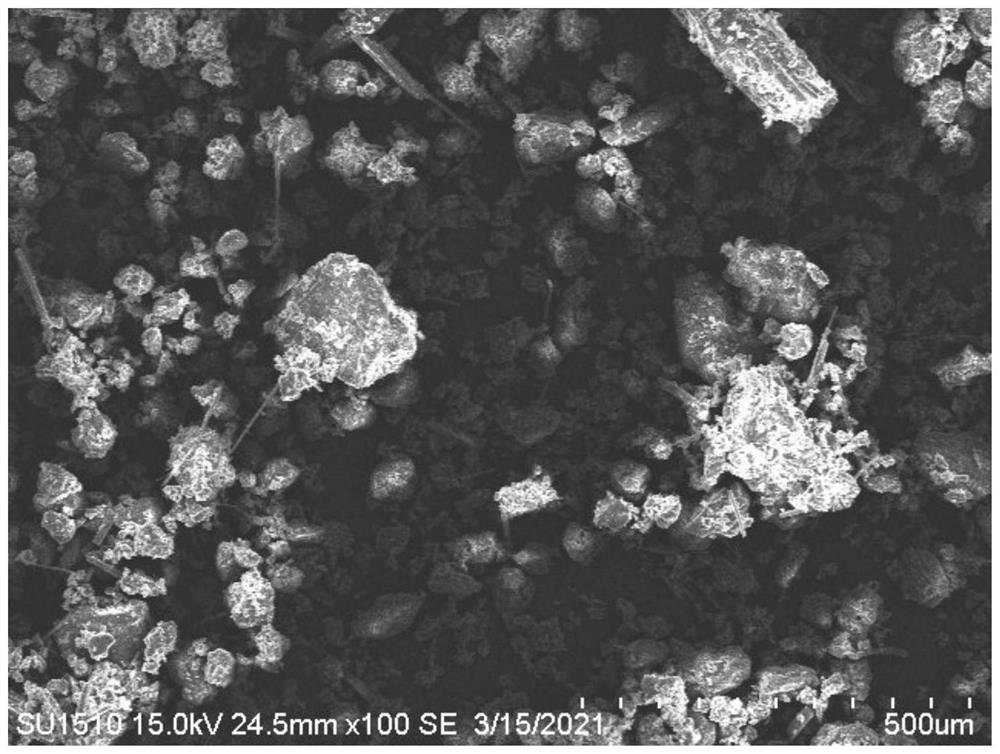

Image

Examples

Embodiment 1

[0038] (1) Freeze-drying: Take an appropriate amount of fresh mussel meat, weigh it, freeze it in a -20°C refrigerator for 4 hours, take it out, put it into a pre-cooled freeze dryer, dry it for 48 hours, and take it out. Freeze dryer model: FD-1A-50. Freeze-drying conditions: below -50°C, vacuum below 1000Pa.

[0039] (2) Grinding: crush the freeze-dried mussel meat with a small universal grinder, pass through an 80-mesh sieve to obtain freeze-dried mussel powder, weigh it, and calculate that the dry weight ratio is about 1:4, that is, 1g mussels The powder is equivalent to the quality of 4g mussel fresh meat, and the mussel powder is stored in a refrigerator at 4°C.

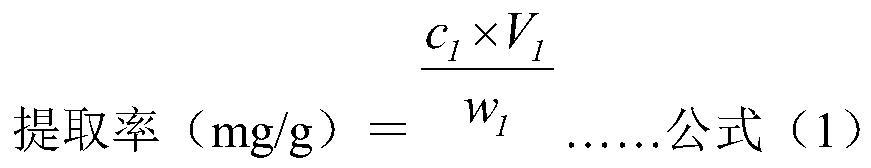

[0040] (3) Extraction: Take 25g of freeze-dried mussel powder, which is equivalent to about 100g of fresh mussel meat, add purified water at a ratio of 1:20, put it in a constant temperature water bath at 60°C, heat and extract for 2 hours, and cool to At room temperature, filter with 4 layers of gauze, and t...

Embodiment 2

[0047] (1) Homogenization: Weigh 100g of fresh mussel meat and put it into a tissue homogenizer for homogenization

[0048](2) Extraction: Add purified water to the homogenate at a material-to-liquid ratio of 1:5, place it in a constant temperature water bath at 60°C, heat and extract for 2 hours, cool to room temperature, filter with 4 layers of gauze, and concentrate the filtrate to its About 1 / 6 times the volume.

[0049] Subsequent steps such as protein removal, purification, determination of extraction amount, concentration, and recrystallization are consistent with steps (3) to (8) in Example 1, and the resulting sample solution has a maximum absorption wavelength at a wavelength of 400nm, which is similar to that of taurine. The standard is the same. After the standard curve of taurine was obtained by measuring taurine standard substance by spectrophotometry, the extraction amount of taurine in fresh mussel meat was determined to be 0.5988 mg / g. After recrystallizatio...

Embodiment 3

[0051] Same as the operation steps of Example 1, under the conditions of 1:5, 1:20, 1:100, and 1:150 respectively at the ratio of solid to liquid, the extraction rate of taurine obtained is respectively 0.7243mg / g, 0.9030mg / g, 0.8876mg / g, 0.7901mg / g. Therefore, the suitable ratio of solid to liquid in this experiment is 1:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com