Preparation method and application of mesoporous aluminum oxide supported noble metal rhodium dehydrogenation catalyst

A technology of aluminum oxide and dehydrogenation catalysts, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., which can solve the need for solvents and time-consuming preparation processes Energy, complex synthesis steps and other issues, to achieve the effect of low energy consumption, rich pore structure, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

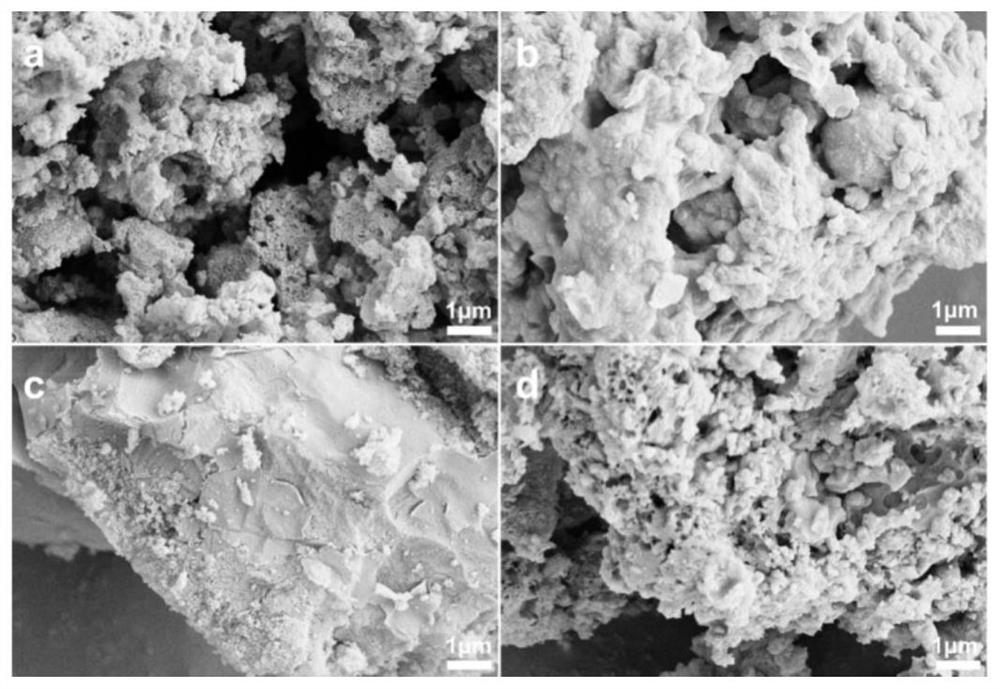

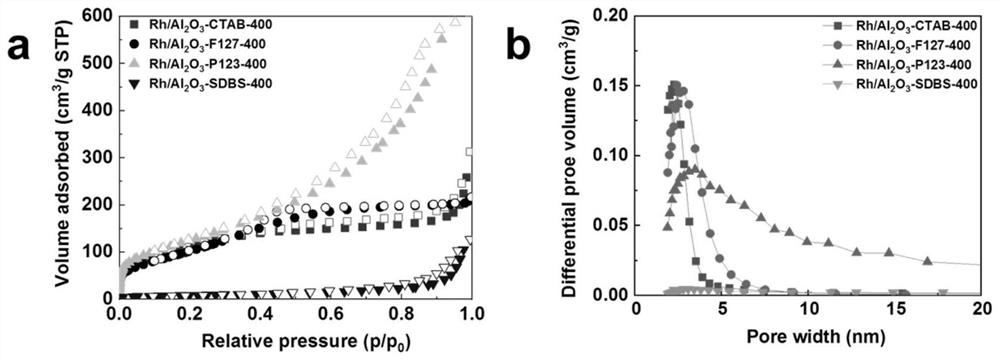

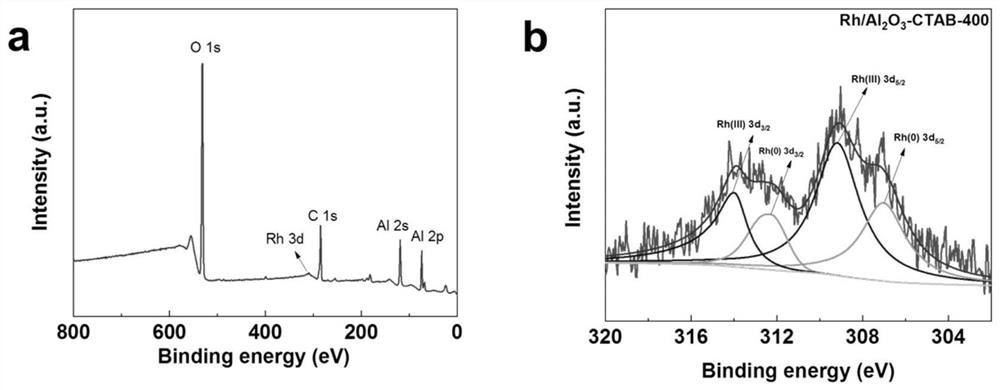

[0025] Embodiment 1: a kind of mesoporous aluminum oxide is responsible for the preparation method of noble metal dehydrogenation catalyst, comprises the following steps:

[0026] (1) Weigh 20mg rhodium trichloride hydrate (RhCl 3 ·3H 2 (2), 2g aluminum isopropoxide, 1gCTAB, mix homogeneously, form mixture;

[0027] (2) Pour the mixture in step (1) into a 50mL ball mill jar, add balls, and mill on a ball mill for 0.5h to obtain Rh / Al 2 o 3 composite materials;

[0028] (3) Put the composite material obtained in step (2) in a porcelain boat, put it into a tube furnace, raise the temperature to 400°C at a rate of 1°C / min in an air atmosphere, keep it warm for 4 hours, and finally cool to room temperature , ground evenly, and the target catalyst was prepared, coded as Rh / Al 2 o 3 -CTAB-400;

[0029] (4) weigh the catalyst Rh / Al prepared in the 5mg step (3) 2 o 3 -CTAB-400, placed in a reaction bottle, measure 2mL ammonia borane aqueous solution with a concentration of 0....

Embodiment 2

[0030] Embodiment 2: a kind of mesoporous aluminum oxide is responsible for the preparation method of noble metal dehydrogenation catalyst, comprises the following steps:

[0031] (1) Weigh 20mg rhodium trichloride hydrate (RhCl 3 ·3H 2 (2), 2g aluminum isopropoxide, 1g F127, mix uniformly to form a mixture;

[0032](2) Pour the mixture in step (1) into a 50mL ball mill jar, add balls, and mill on a ball mill for 0.5h to obtain Rh / Al 2 o 3 composite materials;

[0033] (3) Put the composite material obtained in step (2) in a porcelain boat, put it into a tube furnace, raise the temperature to 400°C at a rate of 1°C / min in an air atmosphere, keep it warm for 4 hours, and finally cool to room temperature , ground evenly, and the target catalyst was prepared, coded as Rh / Al 2 o 3 -F127-400;

[0034] (4) weigh the catalyst Rh / Al prepared in the 5mg step (3) 2 o 3 -F127-400, placed in a reaction bottle, measure 2mL of ammonia borane aqueous solution with a concentration of...

Embodiment 3

[0035] Embodiment 3: a kind of mesoporous aluminum oxide is responsible for the preparation method of noble metal dehydrogenation catalyst, comprises the following steps:

[0036] (1) Weigh 20mg rhodium trichloride hydrate (RhCl 3 ·3H 2 O), 2g aluminum isopropoxide, 1gP123, mix well, form mixture;

[0037] (2) Pour the mixture in step (1) into a 50mL ball mill jar, add balls, and mill on a ball mill for 0.5h to obtain Rh / Al 2 o 3 composite materials;

[0038] (3) Put the composite material obtained in step (2) in a porcelain boat, put it into a tube furnace, raise the temperature to 400°C at a rate of 1°C / min in an air atmosphere, keep it warm for 4 hours, and finally cool to room temperature , ground evenly, and the target catalyst was prepared, coded as Rh / Al 2 o 3 -P123-400;

[0039] (4) weigh the catalyst Rh / Al prepared in the 5mg step (3) 2 o 3 -P123-400, placed in a reaction bottle, measure 2mL of ammonia borane aqueous solution with a concentration of 0.25mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com