Microelectrode integrated sensing chip and application in rapid detection of organic pollutants in water

A sensor chip and micro-electrode technology, applied in the field of electrochemical detection, can solve the problems of long test time, untimely response, secondary pollution, etc., to shorten the detection time, improve the accuracy of detection data, and avoid easy deactivation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

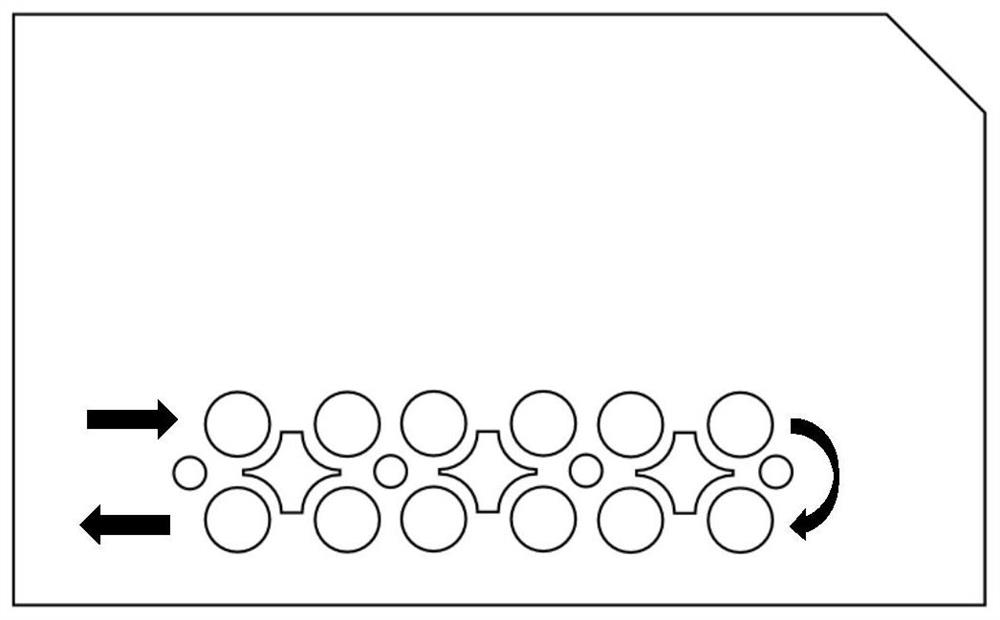

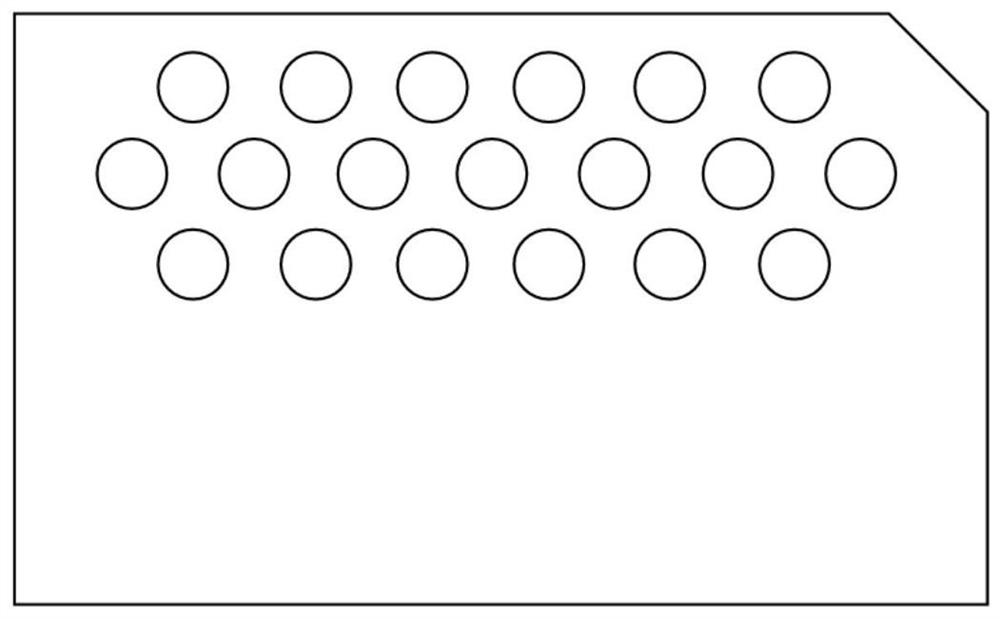

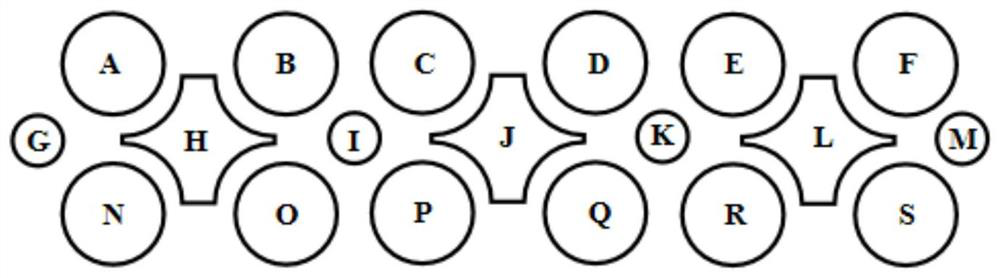

[0068] The front detection area of the microelectrode integrated sensor chip is integrated with multiple microelectrodes, including working electrodes, reference electrodes and counter electrodes. The working electrode includes an electrode layer and a modification layer, the electrode layer includes an electrode base, a conductive inner layer and a reaction layer from bottom to top, and the modification layer is a nanoporous metal modification layer. The electrode layer is specifically the Cu layer of the electrode base layer, the Ni layer of the conductive inner layer and the Au layer of the reaction layer, that is, the nickel-gold electrodeposited on the surface of the copper bottom layer, wherein the thickness of the Cu layer is 10.0-15.0 μm, and the thickness of the Ni layer is 2.0-5.0 μm. The thickness of the Au layer is 0.05-0.10 μm. The periphery of the microelectrode is provided with a circular dam formed by coating with polymer materials to form a micro electrolyti...

Embodiment 2

[0076] The front detection area of the microelectrode integrated sensor chip is integrated with multiple microelectrodes, including working electrodes, reference electrodes and counter electrodes. The working electrode includes an electrode layer and a modification layer, the electrode layer includes an electrode base, a conductive inner layer and a reaction layer from bottom to top, and the modification layer is a nanoporous metal modification layer. The electrode layer is specifically the Cu layer of the electrode base layer, the Ni layer of the conductive inner layer and the Au layer of the reaction layer, that is, the nickel-gold electrodeposited on the surface of the copper bottom layer, wherein the thickness of the Cu layer is 10.0-15.0 μm, and the thickness of the Ni layer is 2.0-5.0 μm. The thickness of the Au layer is 0.05-0.10 μm. The periphery of the microelectrode is provided with a circular dam formed by coating with polymer materials to form a micro electrolyti...

Embodiment 3

[0083] The front detection area of the microelectrode integrated sensor chip is integrated with multiple microelectrodes, including working electrodes, reference electrodes and counter electrodes. The working electrode includes an electrode layer and a modification layer, the electrode layer includes an electrode base, a conductive inner layer and a reaction layer from bottom to top, and the modification layer is a nanoporous metal modification layer. The electrode layer is specifically the Cu layer of the electrode base layer, the Ni layer of the conductive inner layer and the Au layer of the reaction layer, that is, the nickel-gold electrodeposited on the surface of the copper bottom layer, wherein the thickness of the Cu layer is 10.0-15.0 μm, and the thickness of the Ni layer is 2.0-5.0 μm. The thickness of the Au layer is 0.05-0.10 μm. The periphery of the microelectrode is provided with a circular dam formed by coating with polymer materials to form a micro electrolyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com