Screw rod polishing and trimming all-in-one machine

An all-in-one machine and screw technology, applied in the direction of grinding frame, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of uncontrollable quality, poor polishing quality, low degree of automation, etc., and achieve polishing The effect of stable quality, controllable polishing quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

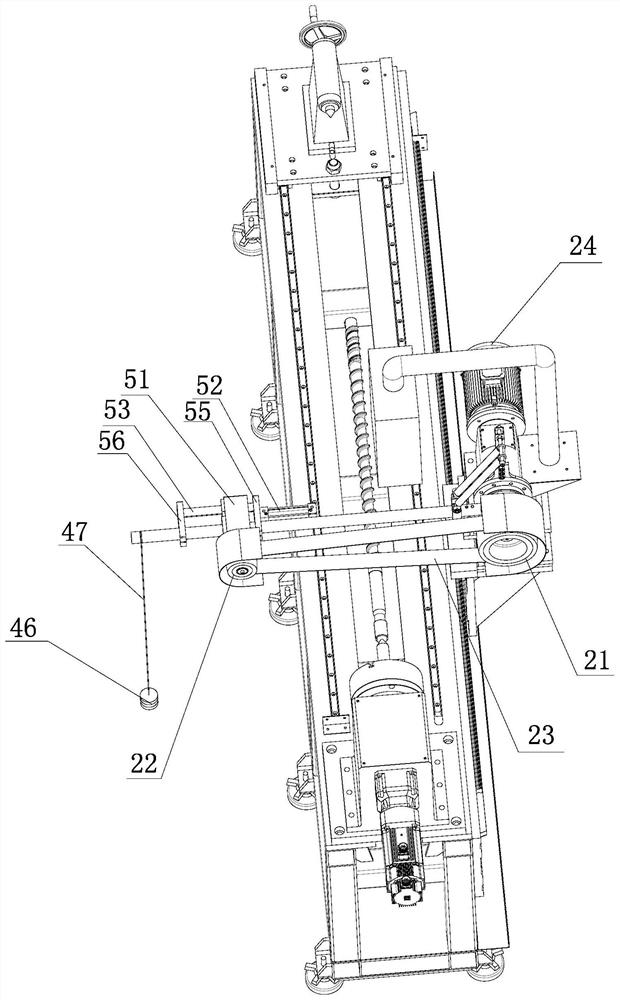

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] By studying the polishing process of the screw, it is concluded that the back angle of the screw and the bottom diameter of the screw are automatically polished by the CNC pitch through the abrasive belt tensioned by the cylinder and can be adjusted at any angle. The angle of 90 degrees or slightly less than 90 degrees; the surface polishing quality of the screw depends on the surface finish of the bottom diameter, rake angle, and rear angle, the consistency of the bottom diameter, and whether the angle between the rake angle and the bottom diameter is 90 degrees Angle or slightly less than 90 degree angle.

[0040] The processing principle of the integrated screw polishing and repairing machine proposed by the present invention is as follows: when the surface of the screw is polished, the main shaft mechanism rotates at a constant spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com