Metal material machining device

A processing device and metal material technology, applied in the direction of metal processing equipment, metal processing machinery parts, sawing machine devices, etc., can solve problems that affect the use, cannot improve work efficiency, and rod body size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

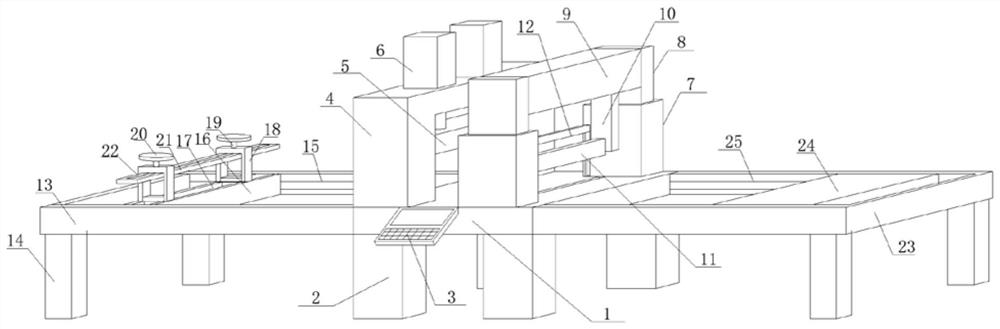

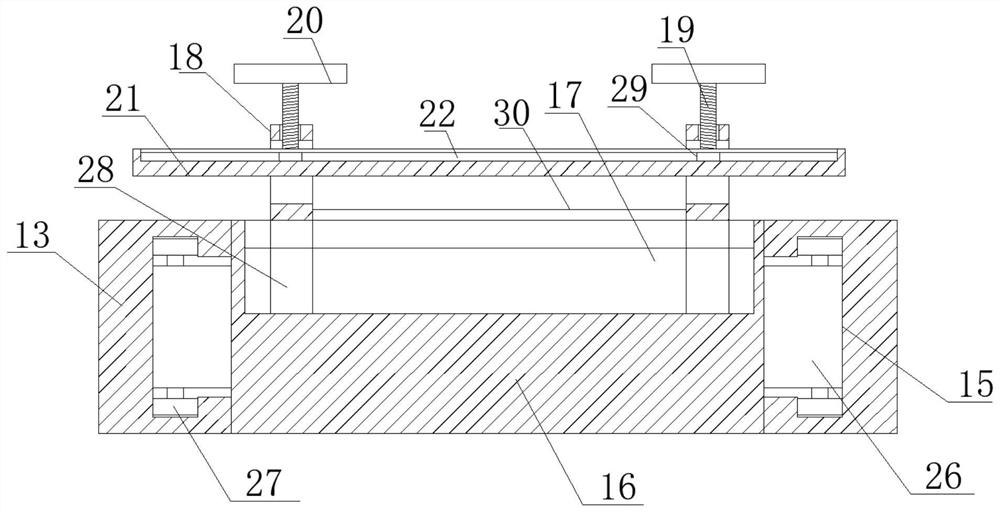

[0027] see figure 1, in an embodiment of the present invention, a metal material processing device includes a fixed base plate 1, a support pole 2 is welded vertically downward on the bottom surface of the fixed base plate 1, a control panel 3 is welded obliquely on one side of the fixed base plate 1, and the fixed base plate The top surface of 1 is welded with a fixed top block 4, and the inner side of the fixed top block 4 is horizontally provided with an extrusion plate 5, and the top surface bolt of the fixed top block 4 is connected with a pushing cylinder 6, and the number of supporting vertical rods 2 is Four, and four support vertical rods 2 are arranged parallel to each other, and the tops of the four support vertical rods 2 are fixed vertically upwards at the four corners of the bottom surface of the fixed base plate 1, and the fixed top block 4 is buckled and fixedly arranged on the fixed top. The top surface of the bottom plate 1 is close to one side, the extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com