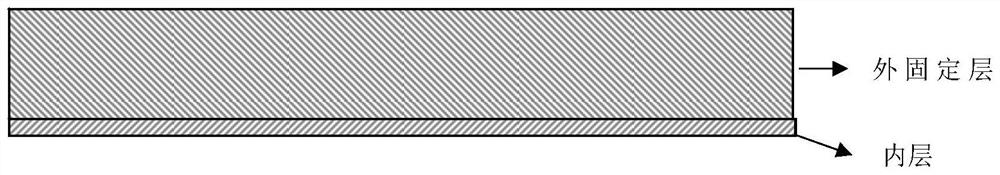

A kind of shape memory high thermal conductivity medical external fixation multi-layer material and preparation method thereof

A multi-layer material, external fixation technology, applied in the field of medical materials, can solve the problems of polycaprolactone tensile strength and elongation at break, low efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0024] (1) Take by weight 100 parts of polycaprolactone PDL-20A, 25 parts of polyethylene oxide WSR-303, 5 parts of glycerol, 1 part of nano-silver supported graphene microsheets, 0.5 part of 2 , 4,6-trimethylbenzoyl-diphenylphosphine oxide crosslinking agent and 0.1 part of photodecomposition accelerator UV-O, at a temperature of 23°C to 25°C, stir and mix at a speed of 100r / min Uniformly, premix A is prepared;

[0025] (2) Weigh 100 parts by weight of silicone rubber TPGC-MY-918, 1 part of graphene microflakes supported by nano-silver, 0.1 part of photodecomposition accelerator UV-O and 0.5 part of 2,4,6-tri Toluyl-diphenylphosphine oxide cross-linking agent, at a temperature of 23°C to 25°C, stir and mix at a speed of 100r / min to prepare premix B;

[0026] (3) Put premix A and premix B into the FJLBIII series multi-layer c...

Embodiment 2

[0031] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0032] (1) Take by weight 100 parts of polycaprolactone PDL-20A, 25 parts of polyethylene oxide WSR-303, 8 parts of glycerol, 3 parts of nano-silver loaded graphene microsheets, 0.5 parts of 2 -Hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone cross-linking agent and 0.08 parts of photodecomposition accelerator UV-9, at a temperature of 23°C to 25°C Under conditions, stir and mix evenly at a speed of 150r / min to prepare premix A;

[0033] (2) 2-methyl-2-(4) of 100 parts of silicone rubber TPGC-MY-918, 5 parts of nano-silver supported graphene microsheets, 0.1 part of photodecomposition accelerator RMB and 0.5 parts by weight -Morpholinyl)-1-[4-(methylthio)phenyl]-1-acetone cross-linking agent, under the temperature condition of 23 ℃ ~ 25 ℃, stir and mix evenly at a speed of 150r / min to prepare the pre- mixture B;

[0...

Embodiment 3

[0039] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0040] (1) Weigh 100 parts by weight of polycaprolactone Solvay 6800, 30 parts of PEO-90M, 10 parts of glycerin, 5 parts of nano-silver loaded graphene microflakes, 1 part of 2-dimethylamino- 2-benzyl-1-[4-(4-morpholinyl)phenyl]-1-butanone crosslinking agent and 0.3 parts of photodecomposition accelerator UVP-327, under the temperature conditions of 23°C to 25°C, Stir and mix evenly at a speed of 150r / min to prepare premix A;

[0041] (2) Weigh 100 parts by weight of silicone rubber MM71791 / 50U, 3 parts of nano-silver supported graphene microflakes, 0.3 parts of photodecomposition accelerator RMB and 1 part of 1-hydroxycyclohexyl phenyl ketone crosslinking agent, at a temperature of 23°C to 25°C, stir and mix evenly at a speed of 150r / min to prepare premix B;

[0042] (3) Put premix A and premix B into the FJLBIII series mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com