Ink-jet printing perovskite light-emitting diode device based on introduction of dielectric layer and preparation method of ink-jet printing perovskite light-emitting diode device

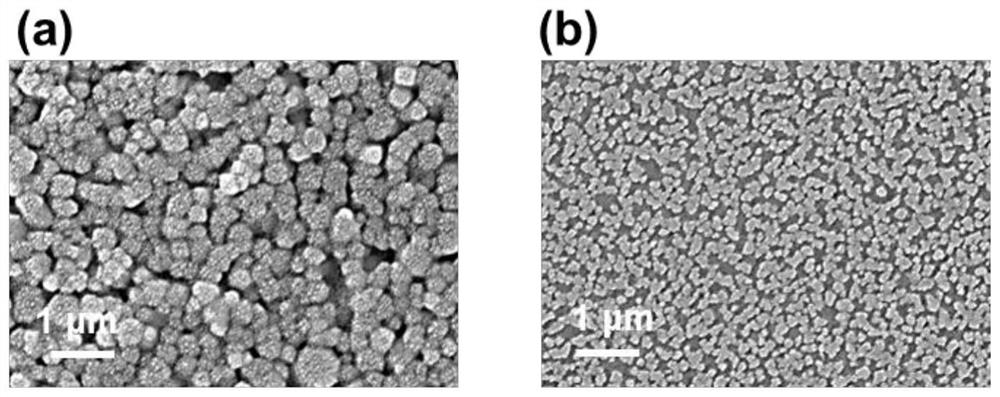

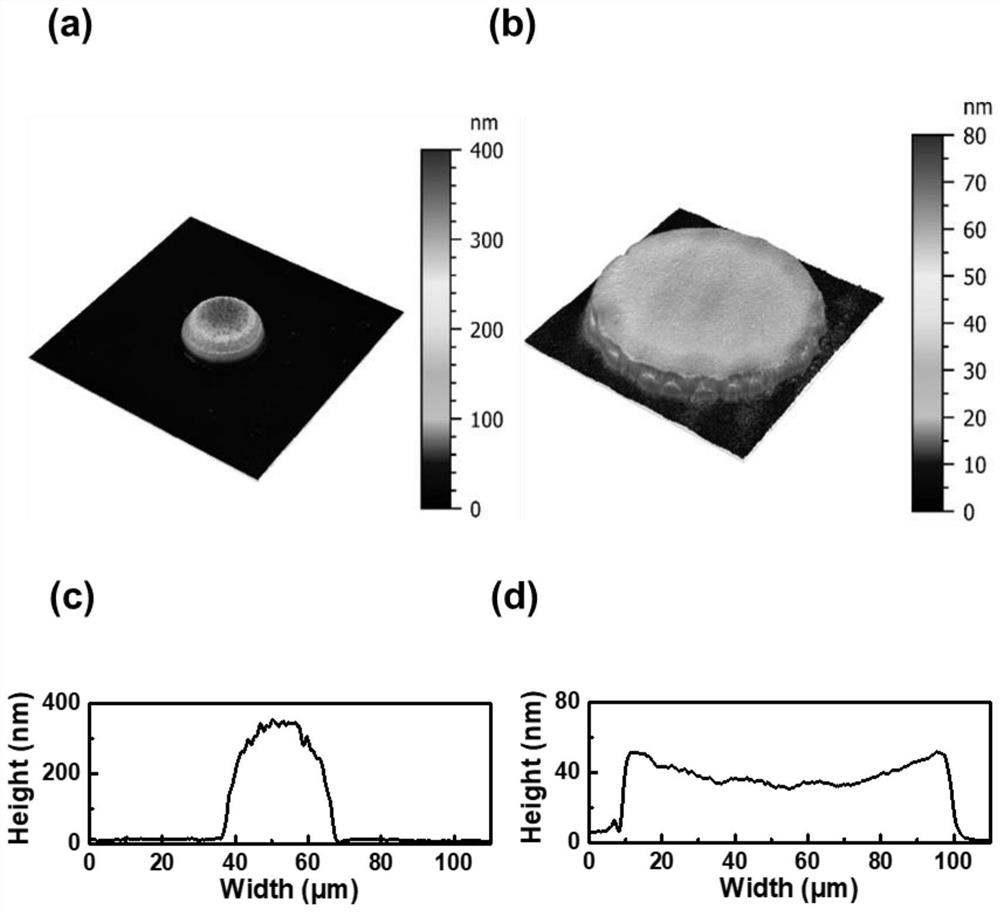

A light-emitting diode and inkjet printing technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problem of uneven morphology of perovskite printed by inkjet printing, so as to suppress adverse effects and induce vertical Effect of growth and reduction of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0048] This embodiment provides an inkjet printing perovskite light emitting diode, such as figure 1 As shown, it includes an anode substrate (thickness is 150nm), hole transport layer (thickness is 40nm), insulating medium layer, active light-emitting layer (thickness is 40nm), electron transport layer (thickness is 40nm) arranged in sequence from bottom to top. 40nm), cathode modification layer (thickness is 2nm) and cathode (thickness is 100nm).

[0049] The above-mentioned method for inkjet printing perovskite light-emitting diodes comprises the following steps:

[0050] 1. Add 0.2mmol PbBr 2 , 0.2mmol CsBr, 0.08mmol PEABr were added to the solution containing crown ether (3.5mg ml -1 ) and PEO (0.3mg ml -1 ) in DMSO (1ml), and stirred at 60°C for 2 hours to obtain a perovskite precursor ink. TFB was dissolved in chlorobenzene solution at a concentration of 8 mg / ml, PVK was dissolved in toluene solution at a concentration of 4 mg / ml, and PVP was dissolved in isopropano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com