High-temperature and corrosion resistant aluminum-containing austenitic stainless steel and preparation method

A technology of austenitic stainless steel and high temperature corrosion resistance, which is applied in the field of materials to achieve the effects of good plasticity and strength, stable corrosion resistance and good mechanical behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention is an aluminum-containing austenitic stainless steel resistant to high temperature corrosion, comprising the following components in weight percentage: Ni: 25%, Cr: 18%, Al: 3%, Mo: 2%, Si: 0.3%, Nb: 0.6 %, C: 0.02%, Y: 0.2%, and the balance is Fe.

[0036] The preparation process is as follows:

[0037] 1) Vacuum smelting is used to prepare ingots;

[0038] 2) Homogenization treatment: raise the temperature of the sample to 1200°C with the furnace, and keep it warm for 2 hours;

[0039] 3) The ingot is forged at 1250°C, the forging ratio is 3:1, and the thickness of the sample after forging is 20mm;

[0040] 4) Solid solution treatment: heat up to 1250°C with the furnace in the heat treatment furnace, keep it warm for 1 hour, and immediately water quench;

[0041] 5) Cut the sample after solid solution, and then carry out anti-oxidation and basic mechanical properties experiments.

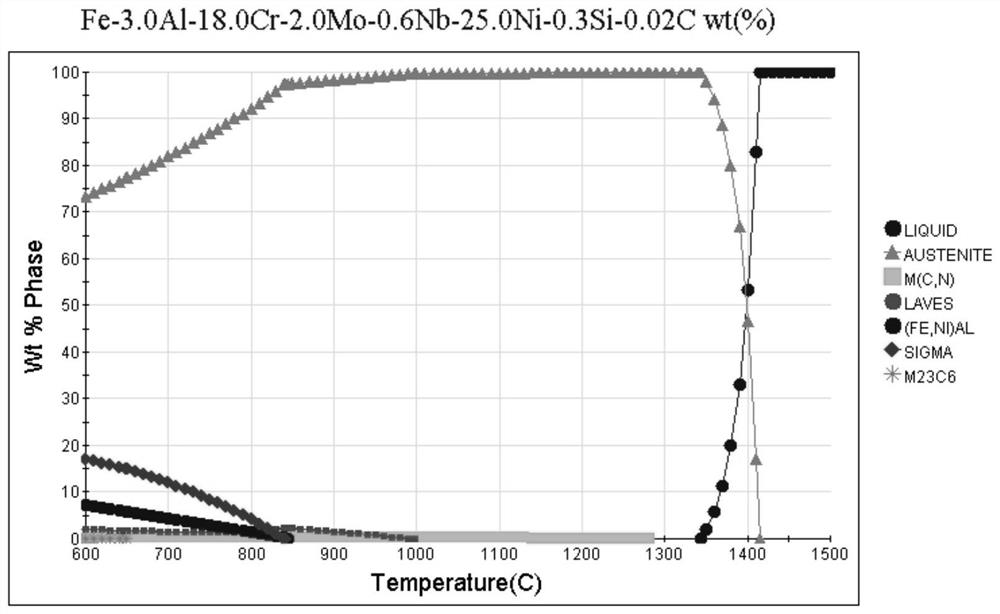

[0042] figure 1 This is the phase diagram of the alloy mater...

Embodiment 2

[0047] The present invention is an aluminum-containing austenitic stainless steel resistant to high temperature corrosion, comprising the following components in weight percentage: Ni: 25%, Cr: 18%, Al: 2.5%, Mo: 2%, Si: 0.3%, Nb: 0.6 %, C: 0.02%, Y: 0.2%, and the balance is Fe.

[0048] The preparation process is as follows:

[0049] 1) Vacuum smelting is used to prepare ingots;

[0050] 2) Homogenization treatment: raise the temperature of the sample to 1200°C with the furnace, and keep it warm for 2 hours;

[0051] 3) Forging the ingot at 1250°C, the forging ratio is 3:1, and the thickness of the sample after forging is 20mm; hot rolling: three times, the total reduction is 60%;

[0052] 4) Solid solution treatment: heat up to 1200°C for 0.5-2 hours, then water quench immediately;

[0053] 5) Cut the sample, and then carry out the basic mechanical property experiment.

[0054] Wherein, the rolling process of step 3) is as follows table 1:

[0055] Table 1 rolling proce...

Embodiment 3

[0058] The difference between this embodiment and embodiment 2 is that the Al content is 3.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com