Photo-crosslinked chitosan-riboflavin edible film and preparation method thereof

A technology of chitosan and riboflavin, applied in the field of food packaging, can solve the problems of poor mechanical property barrier performance, weak bacteriostatic effect, weak antioxidant capacity, etc., and achieves improved antibacterial effect, improved molecular properties and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A 1% (v / v) acetic acid solution was prepared, chitosan powder was weighed and added into the acetic acid solution to form a 2% chitosan (w / v) solution, and magnetically stirred for 4 hours. Glycerin was added according to the glycerol: chitosan ratio of 0.28:1, and then riboflavin with a chitosan content of 1.25% (w / w) was added, and stirred in the dark for 30 minutes to obtain a uniform chitosan-riboflavin mixture.

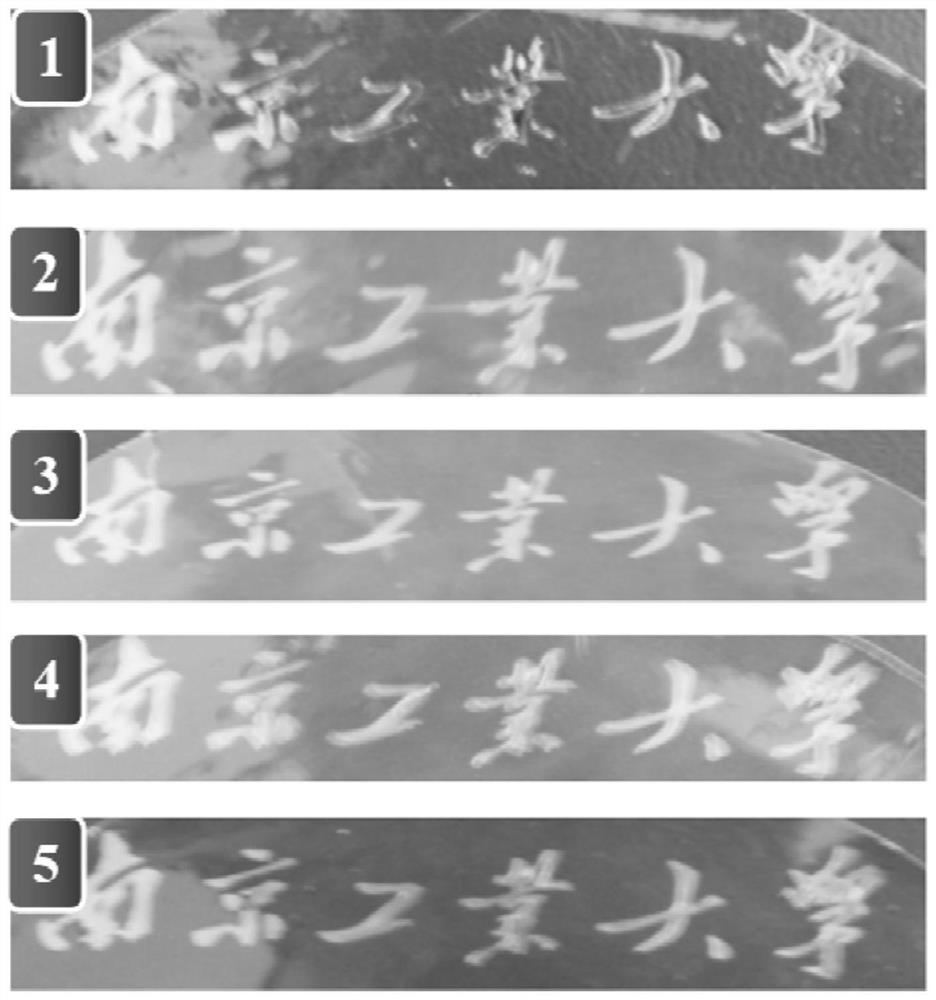

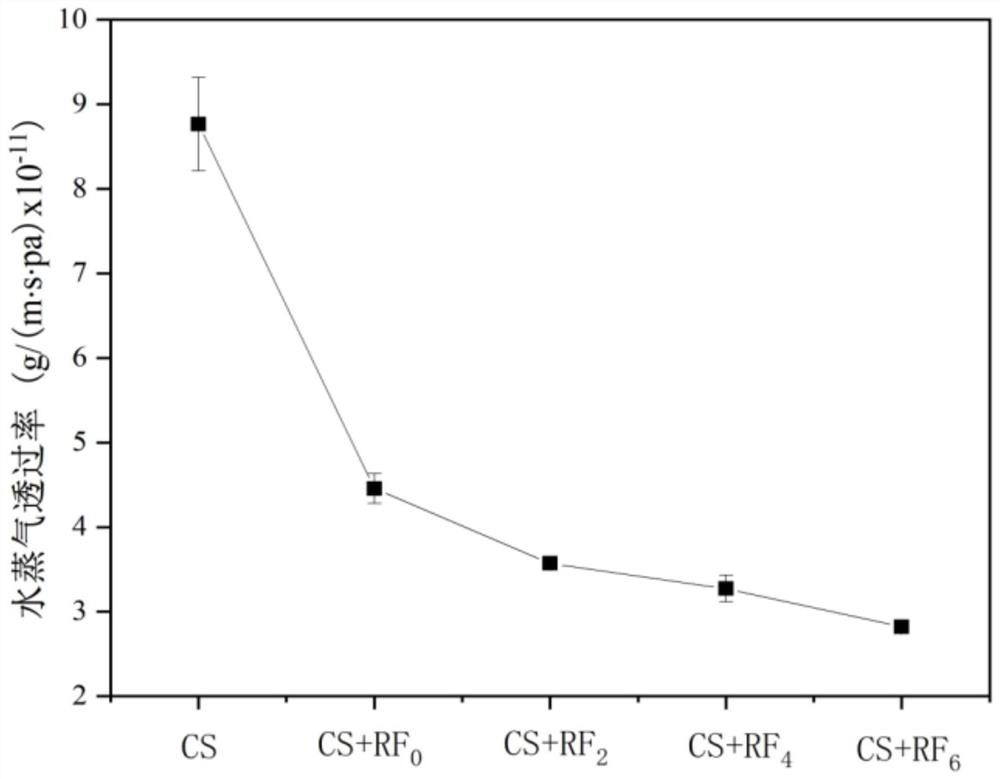

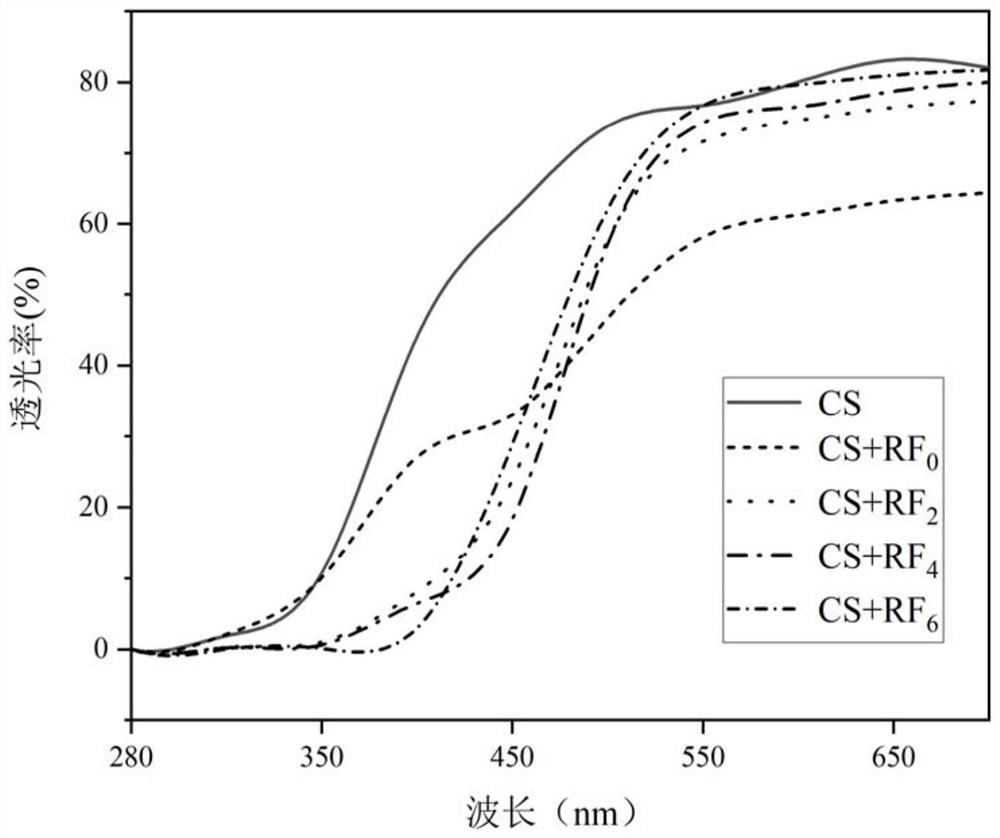

[0047] After the bubbles in the homogeneous mixture were removed by ultrasound, an appropriate amount of the mixture was cast on a flat plate with a diameter of 10 cm and irradiated with 255 nm ultraviolet light for different times, namely 0 h, 2 h, 4 h and 6 h. Finally, the film solutions treated for different times were placed in an oven at 50°C and dried for 5 hours, and the dried film was peeled off from the plate, and placed in an environment of 25°C and 50% relative humidity for 48 hours for later use. A chitosan film without adding riboflavin and wi...

Embodiment 2

[0051] Configure 10% (v / v) acetic acid solution, weigh chitosan powder and add therein, configure 0.5%, 1%, 2%, 3% chitosan (w / v) solution, and magnetically stir for 4 hours. Glycerin was added according to the glycerol: chitosan ratio of 0.28:1, and then riboflavin with a chitosan content of 1.25% (w / w) was added, and stirred in the dark for 30 minutes to obtain a uniform chitosan-riboflavin mixture.

[0052] After the bubbles in the homogeneous mixture were removed by ultrasound, an appropriate amount of the mixture was cast on a flat plate with a diameter of 10 cm and irradiated with 255 nm ultraviolet light for 4 hours. Finally, the film solutions treated for different times were placed in an oven at 50°C and dried for 5 hours, and the dried film was peeled off from the plate, and placed in an environment of 25°C and 50% relative humidity for 48 hours for later use.

[0053] By comparison, it can be found that the thickness of the film prepared by 2% chitosan (w / v) reaches...

Embodiment 3

[0055] A 1% (v / v) acetic acid solution was prepared, chitosan powder was weighed and added into the acetic acid solution to form a 2% chitosan (w / v) solution, and magnetically stirred for 4 hours. Add glycerol according to glycerol: chitosan ratio of 0.1:1, 0.28:1, 0.5:1, 1:1, then add riboflavin with chitosan content of 1.25% (w / w), and stir for 30 minutes in the dark, A uniform chitosan-riboflavin mixture was obtained.

[0056] After the bubbles in the homogeneous mixture were removed by ultrasound, an appropriate amount of the mixture was cast on a flat plate with a diameter of 10 cm and irradiated with 255 nm ultraviolet light for 4 hours. Finally, the film solutions treated for different times were placed in an oven at 50°C and dried for 5 hours, and the dried film was peeled off from the plate, and placed in an environment of 25°C and 50% relative humidity for 48 hours for later use.

[0057] By comparison, it can be found that when the ratio of glycerol: chitosan is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com