Modified solid electrolyte as well as preparation method and application thereof

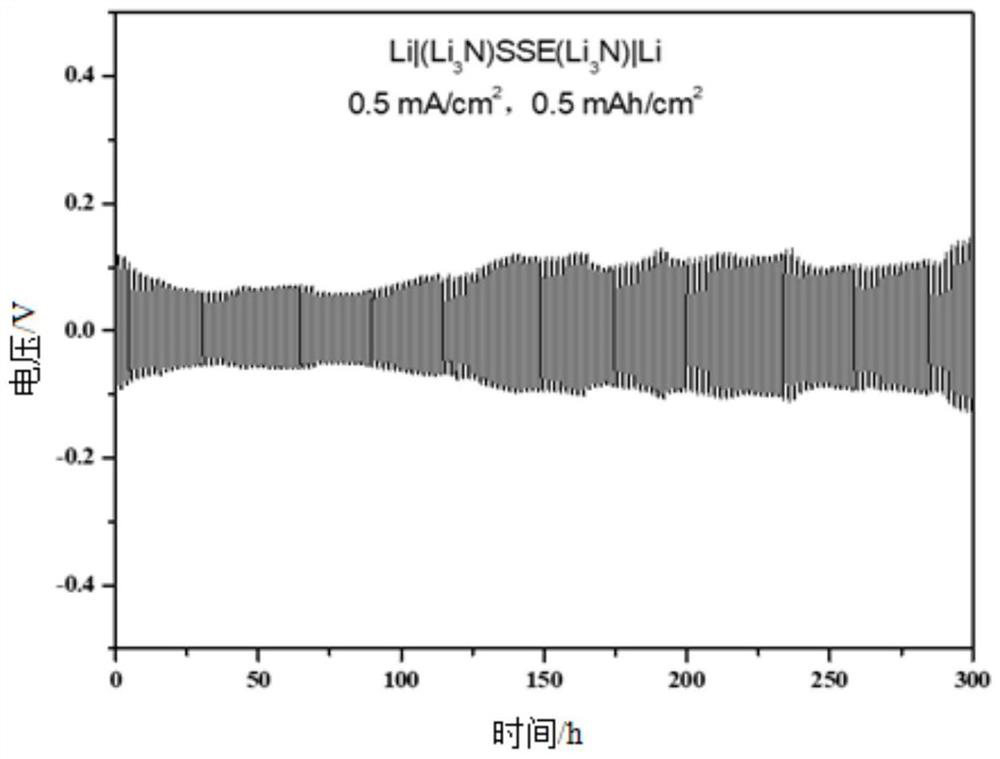

A solid electrolyte and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as uncontrollable safety, battery short circuit, poor safety, etc., achieve good versatility, improve stability, and benefit the industry Magnified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a modified solid electrolyte, and the preparation method of the modified solid electrolyte is as follows:

[0042] (1) Purge the PVDF-based polymer electrolyte with nitrogen before use to remove impurities and dust remaining on the surface, and use non-stick adhesive to fix the oxide electrolyte sheet on the substrate of the high-vacuum thermal evaporation coating device;

[0043] (2) Place the metal lithium sheet in a tantalum evaporation crucible, and control the vacuum degree to 10 -5 Pa, the steam flow rate is Evaporate onto the surface of the oxide electrolyte sheet, and control the thickness of the evaporated layer to 100nm;

[0044] (3) Pass the solid electrolyte deposited with metal lithium obtained in step (2) into high-purity nitrogen gas (99.999%) to react with lithium metal, and generate Li in situ on the surface of the electrolyte 3 The N protective layer is subjected to one isostatic cold pressing under 12Mpa to obtain the modif...

Embodiment 2

[0047] This embodiment provides a modified solid electrolyte, and the preparation method of the modified solid electrolyte is as follows:

[0048] (1) Before using the PEO-based polymer electrolyte, purge the electrolyte with nitrogen gas to remove impurities, dust, etc. remaining on the surface, and use non-stick adhesive to fix the oxide electrolyte sheet on the substrate of the high-vacuum thermal evaporation coating device;

[0049] (2) Place the metal lithium sheet in a tantalum evaporation crucible, and control the vacuum degree to 5×10 -5 Pa, the steam flow rate is , vapor-deposited on the surface of the oxide electrolyte sheet, and the thickness of the vapor-deposited layer is controlled to be 80nm;

[0050] (3) Pass the solid electrolyte deposited with metal lithium obtained in step (2) into high-purity nitrogen gas (99.999%) to react with lithium metal, and generate Li in situ on the surface of the electrolyte 3 The N protective layer is subjected to one isostatic...

Embodiment 3

[0052] The only difference between this embodiment and embodiment 1 is that the thickness of the evaporated layer in step (2) is 50 nm, and other conditions and parameters are exactly the same as those of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com