High-thermal-reliability multi-unit power integration module and processing technology thereof

A technology of power integration and reliability, which is applied in the field of multi-unit power integrated module structure and its processing technology, can solve the problems of high heating temperature of IGBT chips and narrow chopper circuit space, so as to improve heat dissipation efficiency, heat dissipation performance and reliability Sexuality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

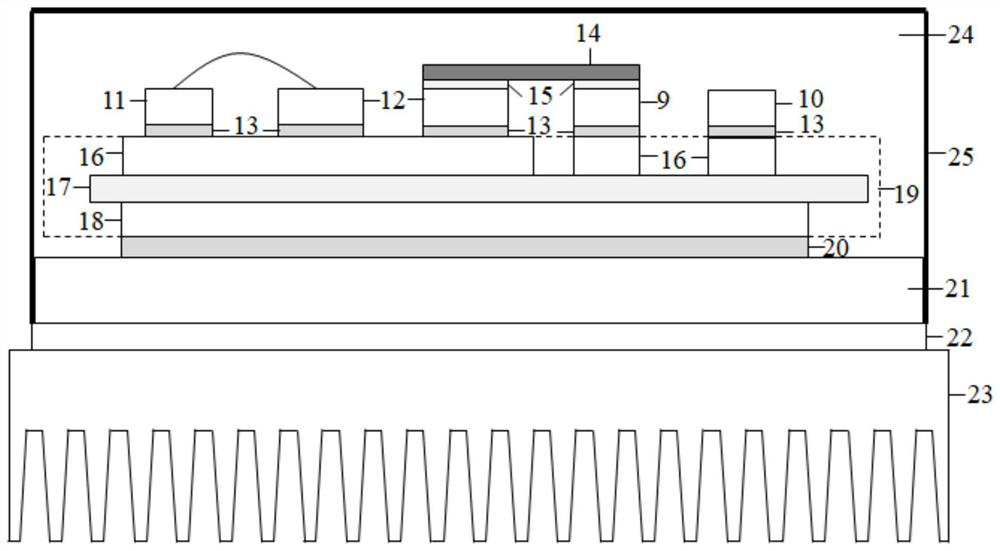

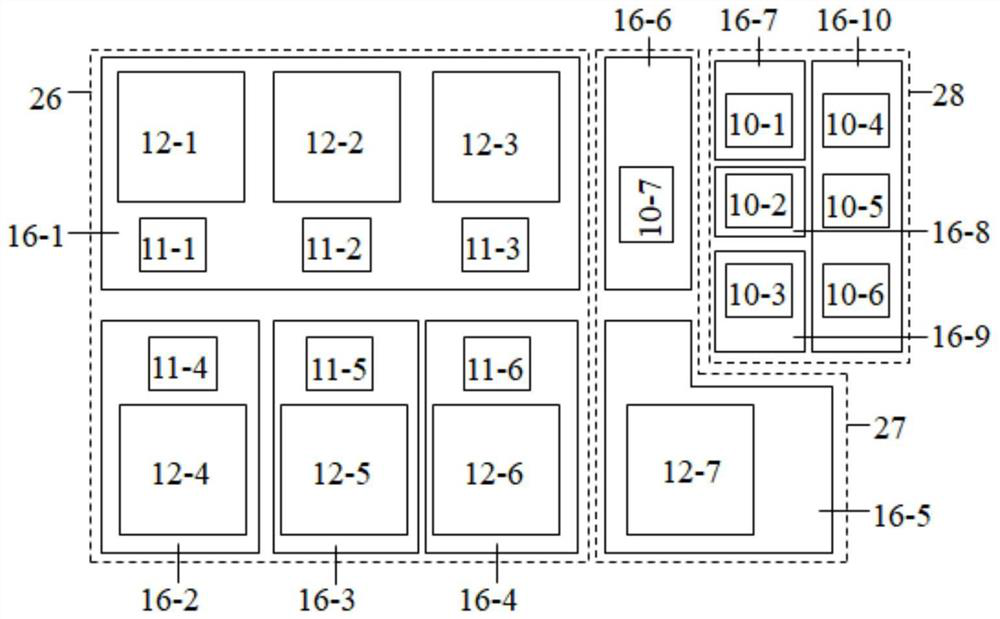

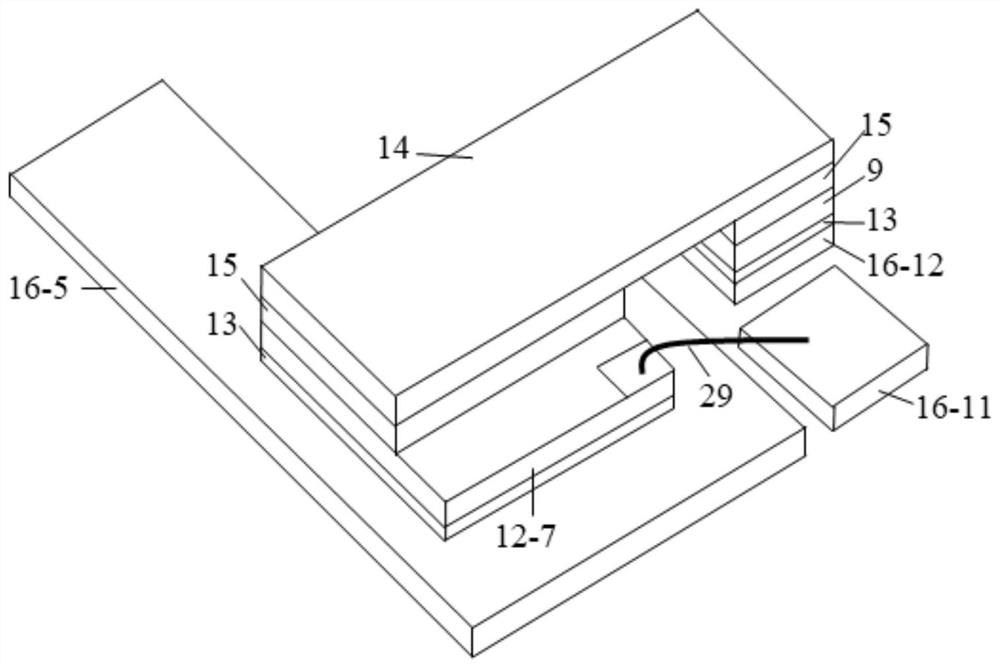

[0034] The present invention proposes a multi-unit PIM structure with high thermal reliability, such as figure 1 As shown, it generally includes from top to bottom: chip layer, upper solder layer 13, copper wiring layer 16, ceramic layer 17, lower copper layer 18, lower solder layer 20, aluminum silicon carbide substrate 21; the copper wiring layer 16, The ceramic layer 17 and the lower copper layer 18 form a DBC liner (copper-clad ceramic liner) 19; the chip layer includes a plurality of silicon-based diode chips 10, silicon carbide SBD chips 11 and silicon-based IGBT chips 12, wherein there are six A silicon-based IGBT (insulated gate bipolar transistor) chip 12 and six silicon carbide SBD (Schottky barrier diode) chips 11 are connected in parallel to form a three-phase bridge inverter circuit 26, which consists of an independent silicon-based IGBT chip 12 A chopper ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com