Semiconductor photoetching machine and use method thereof

A lithography machine and semiconductor technology, applied in the direction of optomechanical equipment, microlithography exposure equipment, optics, etc., can solve the problems of ineffective cooling and waste of water resources, and achieve the goal of increasing flexibility, ensuring effect and speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

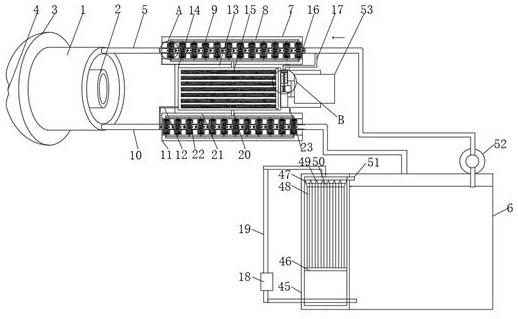

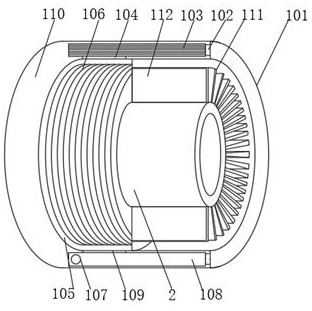

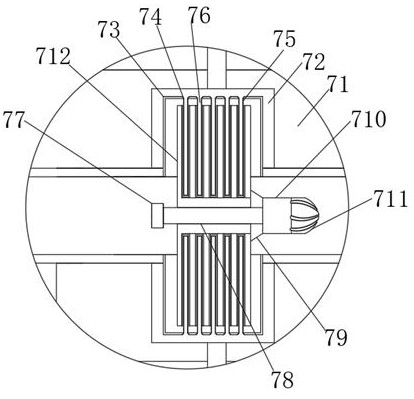

[0033] Such as Figure 1-5 As shown, the present invention provides a semiconductor lithography machine, including: an electrode cover 1, an EUV light emitting end 2 is provided through the inner axis of the electrode cover 1, and the left end of the EUV light emitting end 2 extends to the left of the electrode cover 1 side, the left end of the electrode cover 1 is fixedly connected with a light source lens 3, the middle part of the left side of the light source lens 3 is provided with an EUV light source hole 4, and the upper and lower sides of the right side of the electrode cover 1 are respectively connected with a water inlet pipe 5 and an outlet pipe 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com