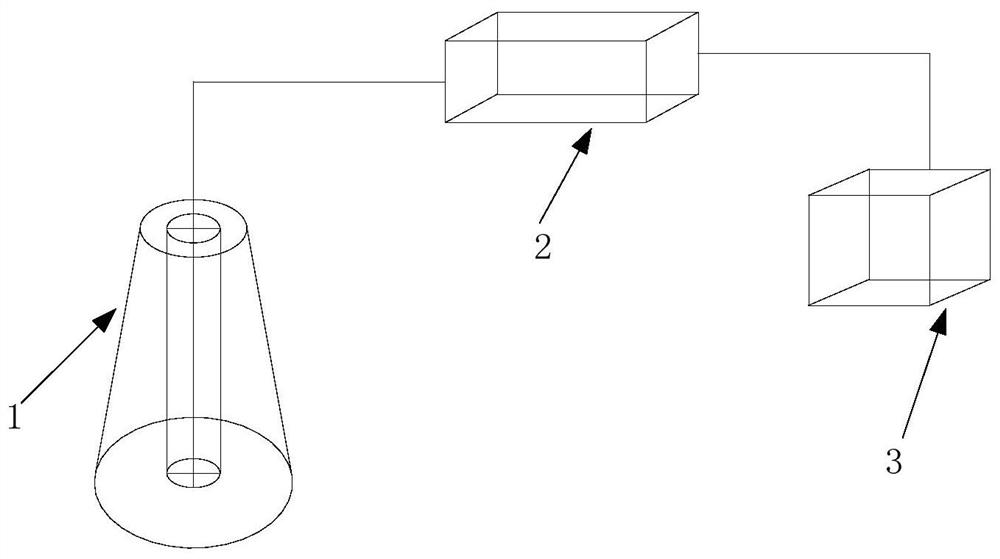

Portable closed gearbox detection device and abnormity judgment method

A detection device and portable technology, applied in the field of hoisting machinery, can solve problems such as potential safety hazards, abnormal jumping of cranes, and inconvenience of inspection, so as to prevent abnormal accidents, solve production safety problems, and improve the safe operation rate of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

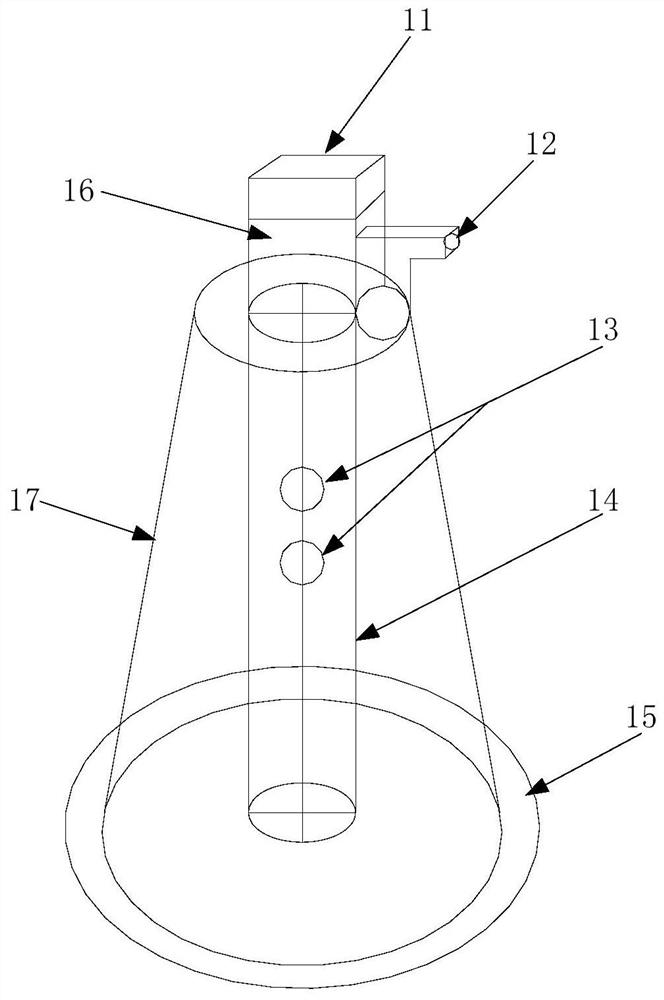

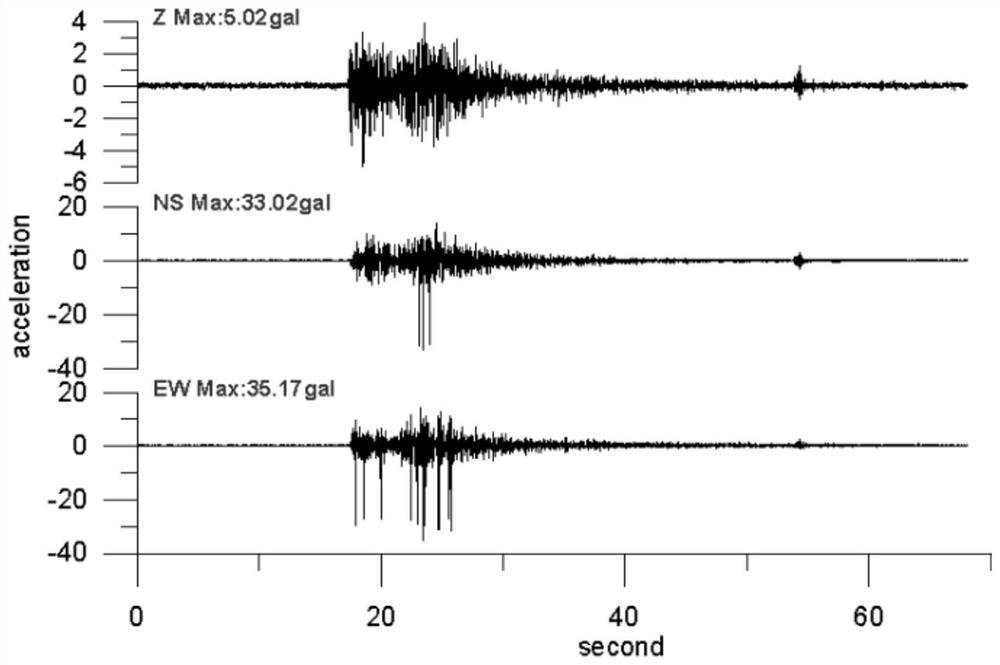

[0053] In the daily inspection, the detector is used to detect the gearbox of the crane. After the excess air is discharged by the air pump, the crane is running and the gear set in the gearbox is running. The detector detects that the vibration wavelength in the gear box is between E and "h<E<H", so the feedback is normal.

Embodiment 2

[0055] In the daily inspection, the detector is used to detect the gearbox of the crane. After the excess air is discharged by the air pump, the crane is running and the gear set in the gearbox is running. The detector detects that the vibration wavelength E in the reduction box exceeds the set range value "h<E<H", and judges that the E wavelength is within the grade 1 mild range, then the recorder starts to record the detection time and status, and The green signal light is on at the computer terminal, warning the detection party to follow up and check the gearbox.

Embodiment 3

[0057] In the daily inspection, the detector is used to detect the gearbox of the crane. After the excess air is discharged by the air pump, the crane is running and the gear set in the gearbox is running. The detector detects that the vibration wavelength E in the gear box exceeds the set range value "h<E<H", and judges that the E wavelength has exceeded the range of level 3. When the red signal light is on, it warns the testing party that the gearbox needs to be stopped immediately for parts replacement and maintenance.

[0058] In order to check the state of the closed reducer of the crane in operation, the present invention overcomes the disadvantages of difficulty in checking the reducer and the inability to visually detect it, and uses a vibration collector to collect the vibration waves generated by the reducer during operation, and uses this as a basis The processing and judgment are carried out to assist the inspectors to effectively monitor the status of the reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com