Anti-deformation SPC floor and preparation method

A technology of anti-deformation and flooring, which is applied in the direction of architecture, building structure, floor, etc., can solve the problems that the substrate is prone to deformation, etc., and achieve the effects of good structural stability, high bonding strength, and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

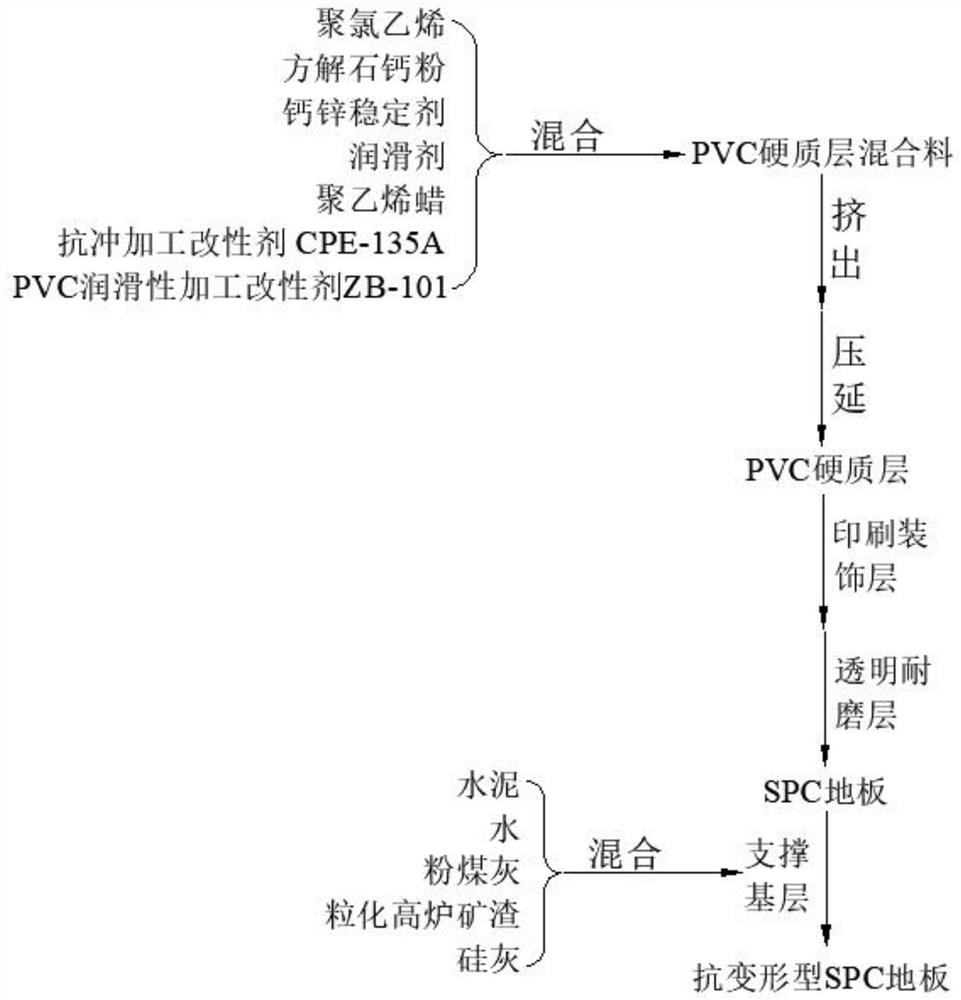

Method used

Image

Examples

Embodiment 1

[0029] A kind of anti-deformation type SPC floor, described anti-deformation type SPC floor comprises support base layer, PVC hard layer, printing decoration layer, transparent wear-resistant layer successively from bottom to top, described support base layer, PVC hard layer, printing decoration layer , The thickness of the transparent wear-resistant layer is 3mm, 6mm, 1mm, 0.5mm in turn;

[0030] The supporting base layer includes the following components in parts by weight: 10 parts of cement, 10 parts of water, 5 parts of fly ash, 4 parts of granulated blast furnace slag, and 2 parts of silica fume;

[0031] The PVC hard layer comprises the following components in parts by weight: 80 parts of polyvinyl chloride, 200 parts of calcite calcium powder, 5 parts of calcium zinc stabilizer, 1 part of lubricant, 1 part of polyethylene wax, 2 parts of impact modifier CPE-135A ACM, 2 parts of PVC lubricity processing modifier ZB-101;

[0032] The particle diameters of the fly ash, g...

Embodiment 2

[0039] A kind of anti-deformation type SPC floor, described anti-deformation type SPC floor comprises support base layer, PVC hard layer, printing decoration layer, transparent wear-resistant layer successively from bottom to top, described support base layer, PVC hard layer, printing decoration layer , The thickness of the transparent wear-resistant layer is 3mm, 6mm, 1mm, 0.5mm in turn;

[0040] The supporting base layer includes the following components in parts by weight: 20 parts of cement, 30 parts of water, 10 parts of fly ash, 10 parts of granulated blast furnace slag, and 5 parts of silica fume;

[0041] The PVC hard layer comprises the following components in parts by weight: 120 parts of polyvinyl chloride, 300 parts of calcite calcium powder, 8 parts of calcium zinc stabilizer, 2 parts of lubricant, 1 part of polyethylene wax, 3 parts of impact modifier CPE-135A ACM, 3 parts of PVC lubricity processing modifier ZB-101;

[0042] The particle diameters of the fly as...

Embodiment 3

[0049] A kind of anti-deformation type SPC floor, described anti-deformation type SPC floor comprises support base layer, PVC hard layer, printing decoration layer, transparent wear-resistant layer successively from bottom to top, described support base layer, PVC hard layer, printing decoration layer , The thickness of the transparent wear-resistant layer is 3mm, 6mm, 1mm, 0.5mm in turn;

[0050] The supporting base layer includes the following components in parts by weight: 16 parts of cement, 16 parts of water, 8 parts of fly ash, 7 parts of granulated blast furnace slag, and 4 parts of silica fume;

[0051] The PVC hard layer comprises the following components in parts by weight: 100 parts of polyvinyl chloride, 300 parts of calcite calcium powder, 5 parts of calcium zinc stabilizer, 1.5 parts of lubricant, 1 part of polyethylene wax, 3 parts of anti-impact processing modifier CPE-135AACM, 3 parts of PVC lubricity processing modifier ZB-101;

[0052] The particle diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com