PA4-66 copolymer material and preparation method thereof

A technology of copolymerization and hexamethylenediamine adipate, which is applied in the field of polymer materials, can solve the problems of poor comprehensive performance of polyamide materials, and achieve the effects of uniform performance, strong chemical bonding and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

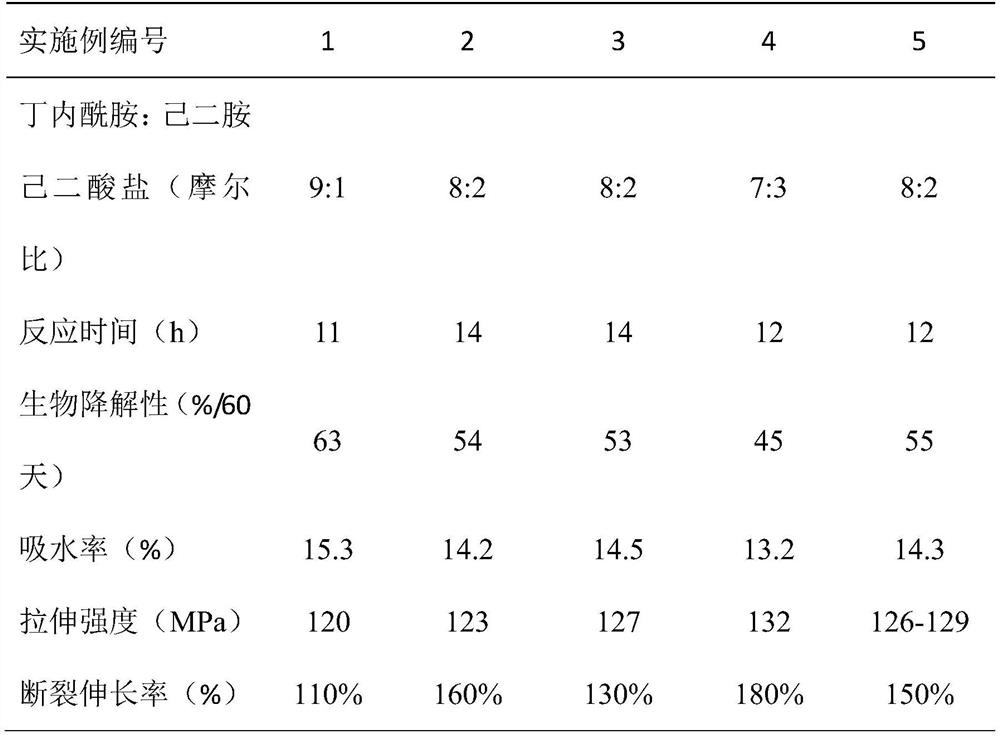

Embodiment 1

[0055] Liquid butyrolactam is mixed with 80% hexamethylenediamine adipate aqueous solution, the molar ratio of butyrolactam to hexamethylenediamine adipate is 9:1, under the condition of 240-250℃ and nitrogen protection Stir continuously in the reactor, and after reacting for 1 hour, turn on the vacuum pump to remove the excess water vapor escaping from the reactants, and keep the pressure of the reactor system constant at slight negative pressure or normal pressure, generally -0.1MPa~0.1MPa is suitable , After continuing the reaction for 10 hours, a PA4-66 copolymer was obtained. After testing, its tensile strength is 120MPa, and its elongation at break is 110%.

Embodiment 2

[0057] Liquid butyrolactam and 80% hexamethylenediamine adipate aqueous solution are mixed in a closed reactor with a molar ratio of 8:2, and the total mass ratio of butyrolactam and hexamethylenediamine adipate is added simultaneously. 0.6% N-ethyl o-toluene sulfonamide, o-p-toluene sulfonamide, under the conditions of 245-260 ℃ and nitrogen protection, keep stirring in the reactor, after 2 hours of reaction, turn on the vacuum pump to pump out the water vapor in the reactor In addition, the pressure of -0.1MPa-0.1MPa is maintained in the reactor, and the PA4-66 copolymer is obtained after 12 hours of reaction. After the copolymer is extruded and cooled, pelletized, hot water extracted and dried with hot nitrogen, PA4-66 is obtained. 66 copolymer slices, the relative viscosity of the copolymer is 2.4-2.7, the tensile strength is 110MPa after testing, and the elongation at break is 160%.

Embodiment 3

[0059] Liquid butyrolactam and 80% hexamethylenediamine adipate aqueous solution are mixed in a closed reactor with a molar ratio of 8:2, and the total mass ratio of butyrolactam and hexamethylenediamine adipate is added simultaneously. 0.3% terephthalic acid, and 0.4% stearic acid, polyethylene wax, under the condition of 245-260 ℃, nitrogen protection, keep stirring in a closed reactor, after 2 hours of reaction, turn on the vacuum pump to remove the water in the reactor The steam is extracted, and the pressure of -0.1MPa-0.1MPa is maintained in the reactor. After 12 hours of reaction, the PA4-66 copolymer is obtained. After extrusion cooling, pelletizing, hot water extraction and hot nitrogen drying, the copolymer is obtained. PA4-66 copolymer chips, the tensile strength of this copolymer is 115MPa, and the elongation at break is 130%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com