High-performance ceramic filler preparation method

A ceramic filler and high-performance technology, applied in the field of high-performance ceramic filler preparation, can solve the problems of equipment parts damage, affecting the service life of equipment, frequent switching of equipment, etc., and achieve the effects of improving processing efficiency, improving service life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

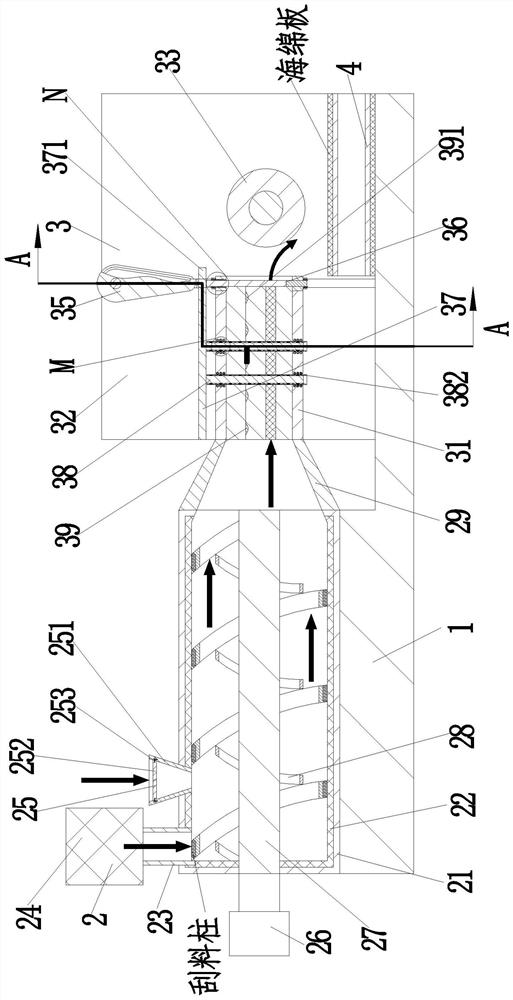

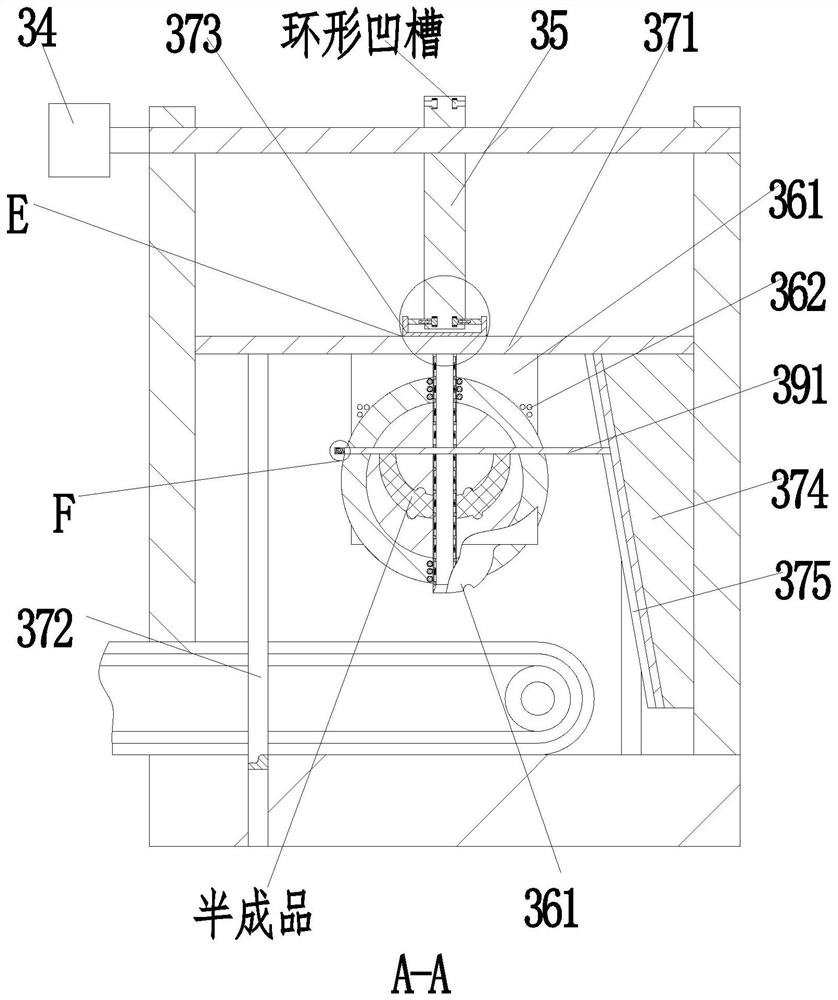

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

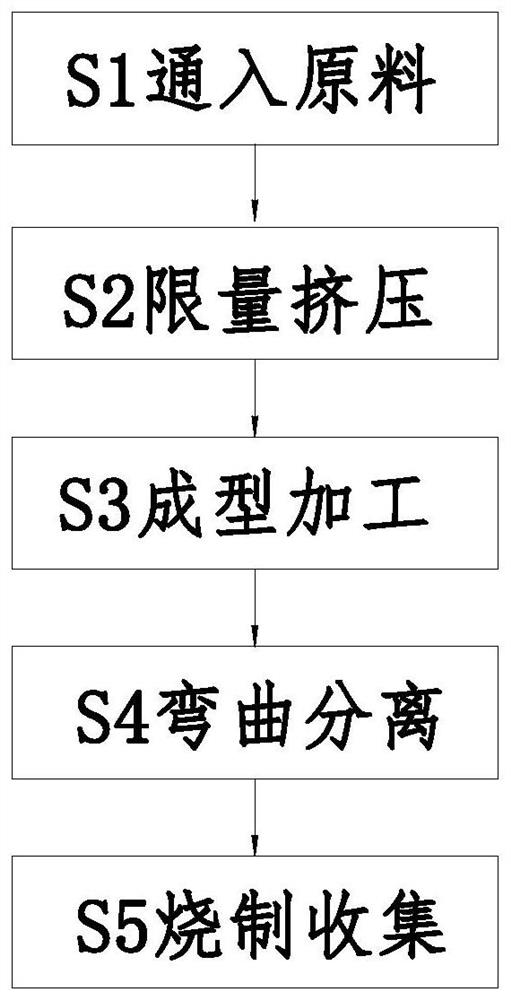

[0042] A high-performance ceramic filler preparation method, which uses a high-performance ceramic filler preparation equipment, the high-performance ceramic filler preparation equipment includes a fixed table 1, a processing device 2, an extrusion device 3 and a belt conveyor 4, using the above-mentioned High-performance ceramic filler preparation equipment The specific method for preparing high-performance ceramic filler is as follows:

[0043] S1. Feed raw materials: pass the raw materials into the feeding pipe 21 through the feeding pipe 23 and the feeding funnel 25, and at this time, the motor one 26 drives the screw rod 27 to evenly stir and transport the raw materials;

[0044] S2. Limited extrusion: through the conical cylinder 29, the unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com