A fuel cell catalytic layer slurry and its preparation method and application

A fuel cell and catalytic layer technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as unsuitable for large-scale production, poor dispersion of carbon nanotubes, poor performance of membrane electrodes, etc., to reduce total platinum The effects of loading capacity, optimizing pore structure, reducing contact resistance and mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention also proposes a method for preparing fuel cell catalyst layer slurry, which includes the following steps:

[0035] a, mixing carbon nanotubes, graphene and dispersant uniformly to obtain the first slurry mixture;

[0036]b, adding deionized water to the Pt / C catalyst to wet the catalyst, after mixing evenly, adding the solvent and the first slurry mixture obtained in step a in sequence, and performing ball milling to obtain the second slurry mixture;

[0037] c. Add a perfluorosulfonic acid resin solution to the second slurry mixture obtained in step b, and perform ball milling to obtain a catalytic layer slurry.

[0038] According to the preparation method of fuel cell catalyst layer slurry in the embodiment of the present invention, carbon nanotubes and graphene are mixed in advance to form the first slurry mixture, and a dispersant is added during the mixing process to make carbon nanotubes and graphene Can be well dispersed, ...

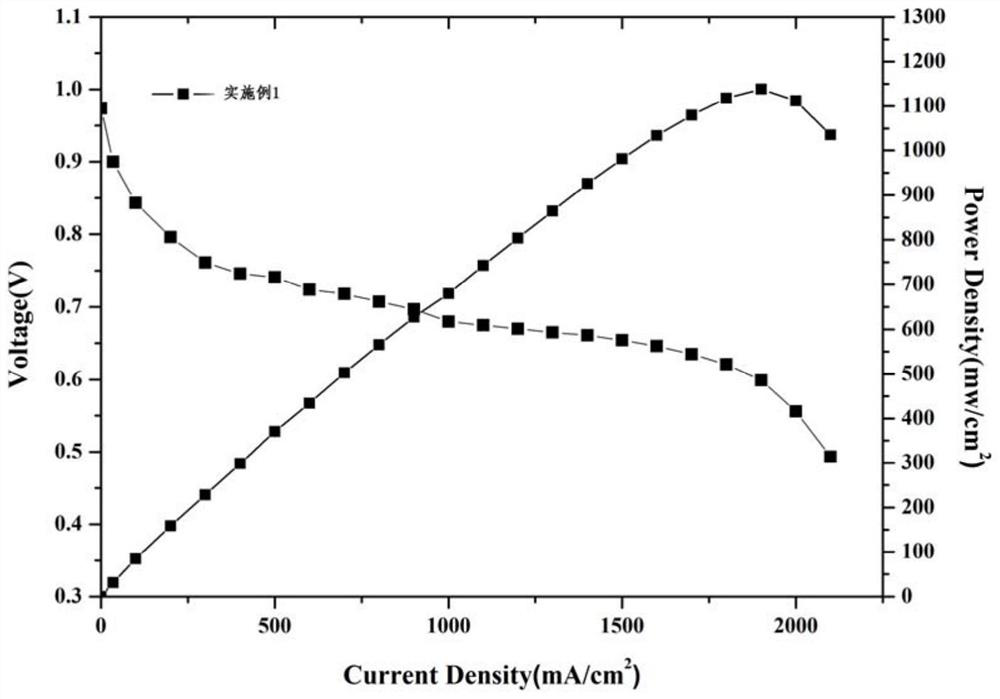

Embodiment 1

[0047] 1. Preparation of fuel cell catalyst layer slurry

[0048] 2.5 parts by weight of carbon nanotubes, 2.5 parts by weight of graphene and 2.5 parts by weight of dispersant polyvinyl alcohol are mixed and stirred evenly to obtain the first slurry mixture; 100 parts by weight of Pt / C (50%) catalyst is weighed and put into a ball mill In the tank, use a dropper to add 250 parts by weight of deionized water to fully wet the catalyst. After mixing evenly, add 800 parts by weight of n-propanol and the pre-mixed first slurry mixture in sequence, and add 500 parts by weight of zirconia grinding balls , after the ball milling tank is sealed, put it into an automatic ball mill for ball milling, the rotating speed is 300r / min, and the ball milling time is 4h to obtain the second slurry mixture; then take out the ball milling tank, and add 80 parts by weight to the second slurry mixture slurry For the perfluorosulfonic acid resin, the perfluorosulfonic acid resin was prepared into a ...

Embodiment 2

[0057] The preparation method is the same as in Example 1, except that the proportion of the catalyst layer slurry is different, specifically 100 parts by weight of Pt / C catalyst, 250 parts by weight of deionized water, 750 parts by weight of n-propanol, and 100 parts by weight of ethanol , 4 parts by weight of carbon nanotubes, 1 part by weight of graphene, 5 parts by weight of dispersant polyacrylic acid and 70 parts by weight of perfluorosulfonic acid resin.

[0058] The battery made in this embodiment has a current density of 900mA / cm at 0.7V 2 , at 0.6V, the current density is 1800mA / cm 2 , the maximum power density can reach 1120mw / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com