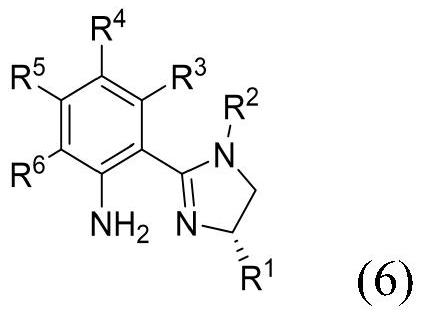

Chiral 2-imidazoline aniline compound as well as preparation method and application thereof

A technology of imidazoline aniline and compound is applied in the field of chiral catalysts and achieves the effects of mild conditions, simple synthesis method and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

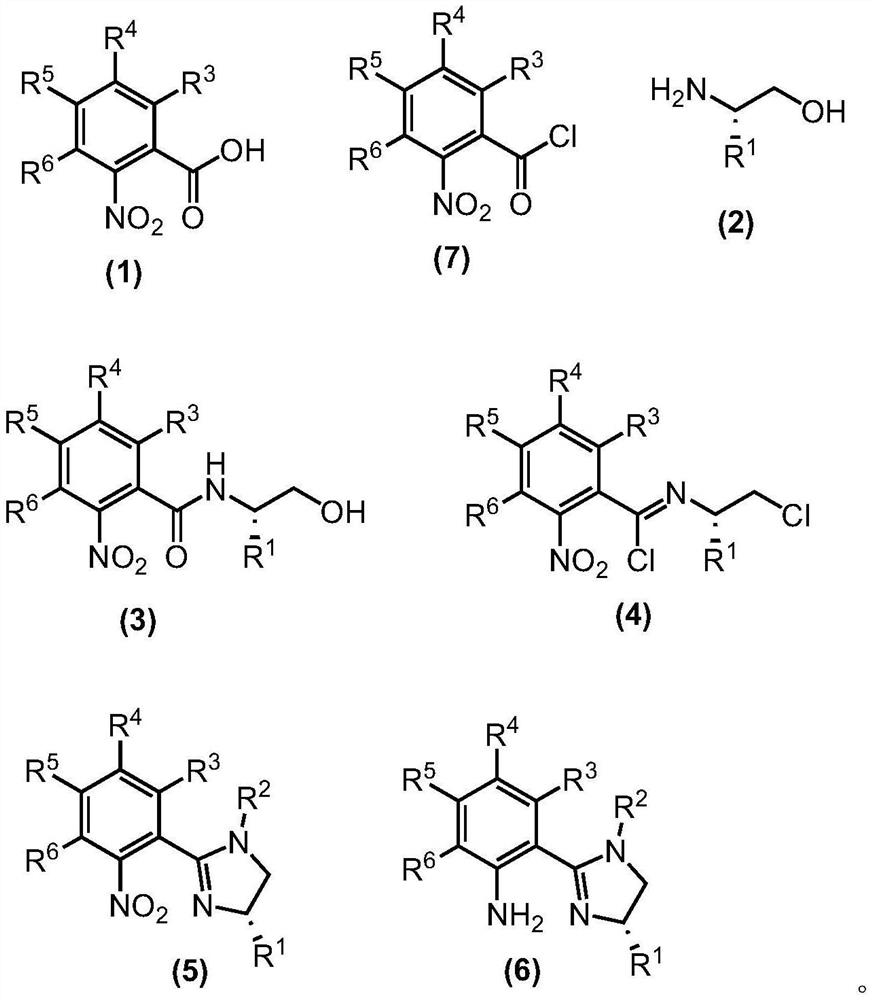

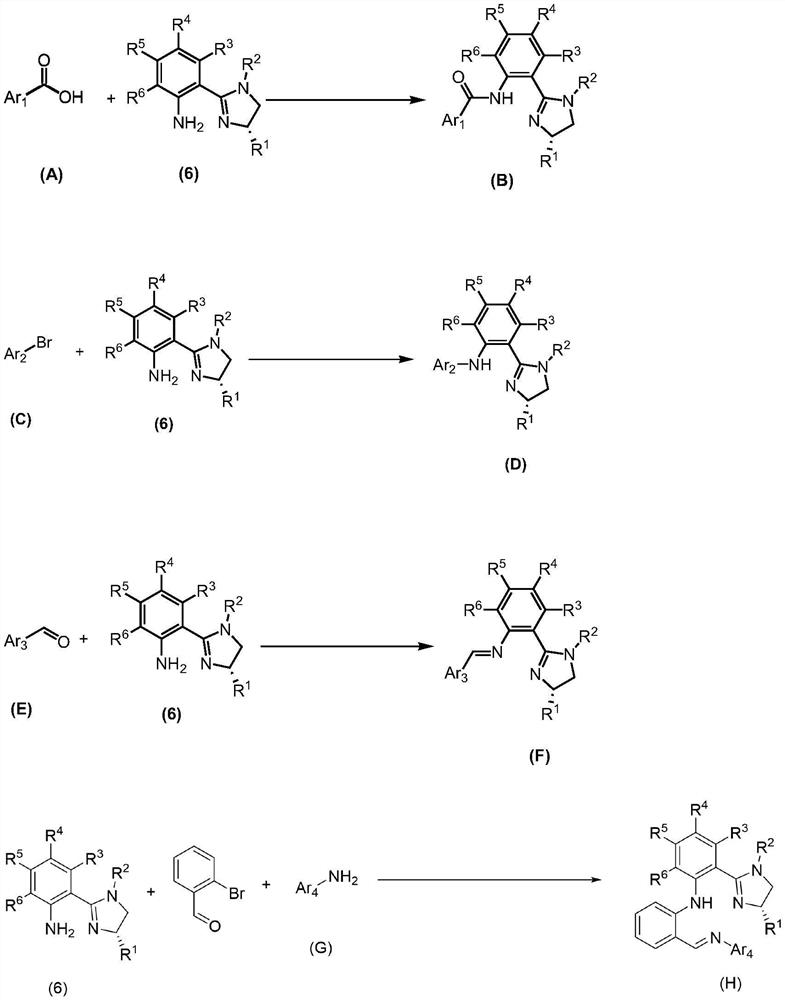

Method used

Image

Examples

Embodiment 1

[0055] (1) Add 16.7g (100mmol) of o-nitrobenzoic acid, 100mL of dichloromethane and 2 drops of N,N-dimethylformamide in a 250mL round bottom flask, slowly add oxalyl chloride (150mmol) dropwise at room temperature, After reacting for 5-8 hours, dichloromethane and excess oxalyl chloride were removed under reduced pressure to obtain o-nitrobenzoyl chloride without purification; the preparation reaction equation is as follows:

[0056]

[0057] (2) Add 0.5151g (5mmol) S-valinol, 20mL dichloromethane and 1.4mL (10mmol) triethylamine into a 100mL round bottom flask, stir well, add 0.6mL (5mmol) o-nitrate under ice bath Base benzoyl chloride, after the addition, was warmed up to room temperature and stirred for 8 hours; the reaction solution was washed with water and saturated brine successively, separated after washing, and the organic phase was dried with anhydrous sodium sulfate, and concentrated to obtain N-[(1S)-2 -Methyl-1-hydroxymethylpropyl]-2-nitrobenzamide (3b), withou...

Embodiment 2

[0064] (1) With step (1) in embodiment 1.

[0065] (2) Same as step (2) in Example 1, wherein the difference is that 0.5151g S-valinol is changed to 0.5948g (5mmol) S-isoleucinol to obtain N-[(1S)-1-isoleucinol Butyl-2-hydroxyethyl]-2-nitrobenzamide crude product (3c), without purification; white solid; the preparation reaction equation is as follows:

[0066]

[0067] (3) With step (3) in embodiment 1, wherein difference is that the crude product of N-[(1S)-2-methyl-1-hydroxymethyl propyl]-2-nitrobenzamide is changed into N -[(1S)-1-Isobutyl-2-hydroxyethyl]-2-nitrobenzamide crude product to give 2-[(4S)-4-isobutyl-N-phenyl-2-imidazole Linyl] nitrobenzene crude product (5c), without purification; the preparation reaction equation is as follows:

[0068]

[0069] (5) Same as step (4) in Example 1, wherein the difference is that the crude product of [(4S)-4-isopropyl-N-phenyl-2-imidazolinyl]nitrobenzene is changed to [(4S) -4-isobutyl-N-phenyl-2-imidazolinyl]nitrobenzen...

Embodiment 3

[0072] (1) With step (1) in embodiment 1.

[0073] (2) With step (2) in embodiment 1, wherein different is that 0.5151g S-valinol is changed into 0.5948g (5mmol) S-secondary leucinol, obtains N-[(1S)-1-secondary Butyl-2-hydroxyethyl]-2-nitrobenzamide crude product (3d), without purification; white solid; the preparation reaction equation is shown in the following formula:

[0074]

[0075] (3) With step (3) in embodiment 1, wherein difference is that the crude product of N-[(1S)-2-methyl-1-hydroxymethyl propyl]-2-nitrobenzamide is changed into N -[(1S)-1-sec-butyl-2-hydroxyethyl]-2-nitrobenzamide crude to give 2-[(4S)-4-sec-butyl-N-phenyl-2-imidazole Linyl] nitrobenzene crude product (5d), without purification; the preparation reaction equation is shown in the following formula:

[0076]

[0077] (4) With step (4) in embodiment 1, wherein difference is that [(4S)-4-isopropyl-N-phenyl-2-imidazolinyl] nitrobenzene crude product is changed into [(4S) -4-sec-butyl-N-pheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com